Gravity shaft depth measuring device and method

A technology of depth measurement and sliding well, which is applied in mining equipment, earth-moving mining, transportation and packaging, etc., can solve the problems of grid-like barriers, irregular shape of sliding well, low degree of automation, etc., to facilitate centralized management, Excellent durability and reliability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

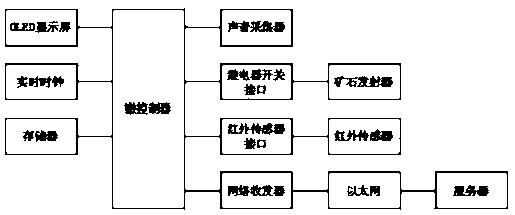

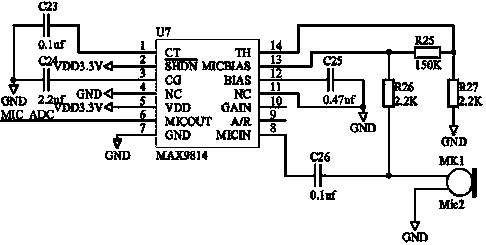

[0029] The chute depth measuring device provided by the present invention comprises a housing, which is provided with a display screen, a sensor interface, a relay switch interface, a network transceiver, a sound collector interface, and a real-time clock. The housing is provided with a microcontroller, and The microcontroller is electrically connected to the memory, wherein the display screen on the housing, the sensor interface, the relay switch interface, the network transceiver, the sound collector interface, and the real-time clock are all electrically connected to the microcontroller, and the sensor interface and the sound collector interface They are respectively electrically connected to the sensors and sound collectors installed in the measured area, the network transceiver is connected to the server signal through Ethernet, and the relay switch interface is el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com