Clamping device and method for two-for-one twister winding bobbin

A double twister and bobbin technology, which is applied to the winding bobbin clamping device and the clamping field of the double twister, can solve the problems of high labor repetition, cumbersome bobbin taking process, low production efficiency, etc., and achieves compact size and control accuracy. High and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

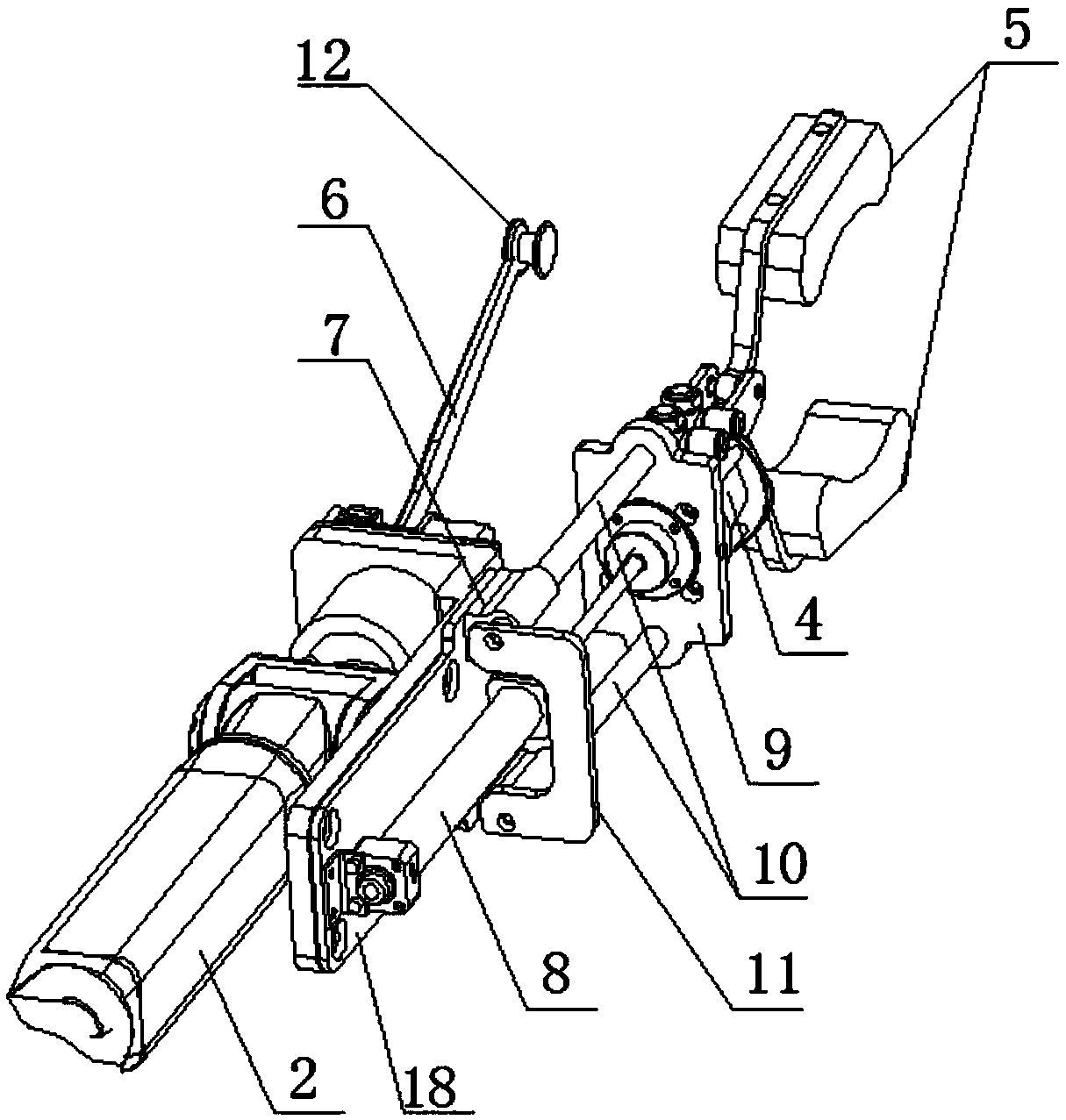

[0033] Such as figure 1 , image 3 and Figure 4 As shown, the winding bobbin clamping device of the two-for-one twister of this embodiment includes an electric cylinder trolley 1 provided with a lifting platform, a robot 2 is installed on the lifting platform, and a telescopic mechanism 3 is fixedly installed on one side of the operating arm of the robot 2. The front end of the telescopic mechanism 3 is equipped with a clamping mechanism 4, and two grippers 5 are installed on its head, and the front end of the robot 2 operating arm is equipped with a lifting operator 6; it also includes a two-for-one twister winding mechanism 13, on which the upper bobbin The coupling 16 is fitted with a plurality of winding bobbins 14 .

[0034] Such as figure 2 As shown, the installation structure of the telescopic mechanism 3 is as follows: a moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com