Hybrid tractor continuously variable transmission

A continuously variable transmission and hybrid technology, which is applied to the arrangement of multiple different prime movers of power units, general power units, and pneumatic power units, etc. Torque change and other issues, to achieve the effect of wide speed change range, compact transmission structure and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

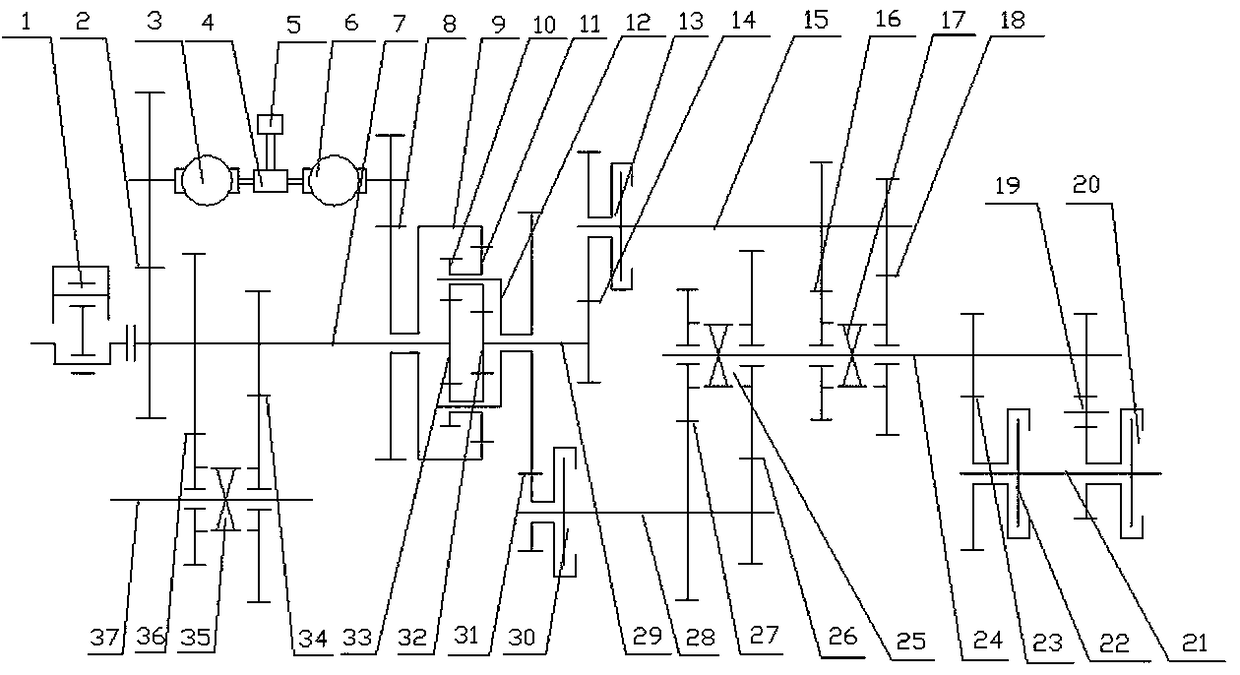

[0017] Such as figure 1 As shown, a kind of hybrid tractor continuously variable transmission of the present invention comprises electric power system, transmission input shaft 7, transmission output shaft 21 and compound planetary gear mechanism, transmission input shaft 7 and transmission output shaft 21 are mutually flat and the ends are uniform The rotation is arranged on the casing of the speed change device.

[0018] The electric power system includes a first motor generator 3 and a second motor generator 6 , both of which are electrically connected to a battery 5 through a power controller 4 . The power controller 4 can be switched to make the storage battery 5 supply power to the first generator motor or the second generator motor to output torque, and the power controller 4 can also be switched to make the first generator motor and or the second generator motor generate electricity and charge the battery 5 in.

[0019] The compound planetary gear mechanism includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com