Optical non-contact high-speed detection system

A detection system, non-contact technology, applied in sorting and other directions, can solve the problems of screw gauge breakage, injury, low pass rate, etc., and achieve the effect of preventing jamming and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

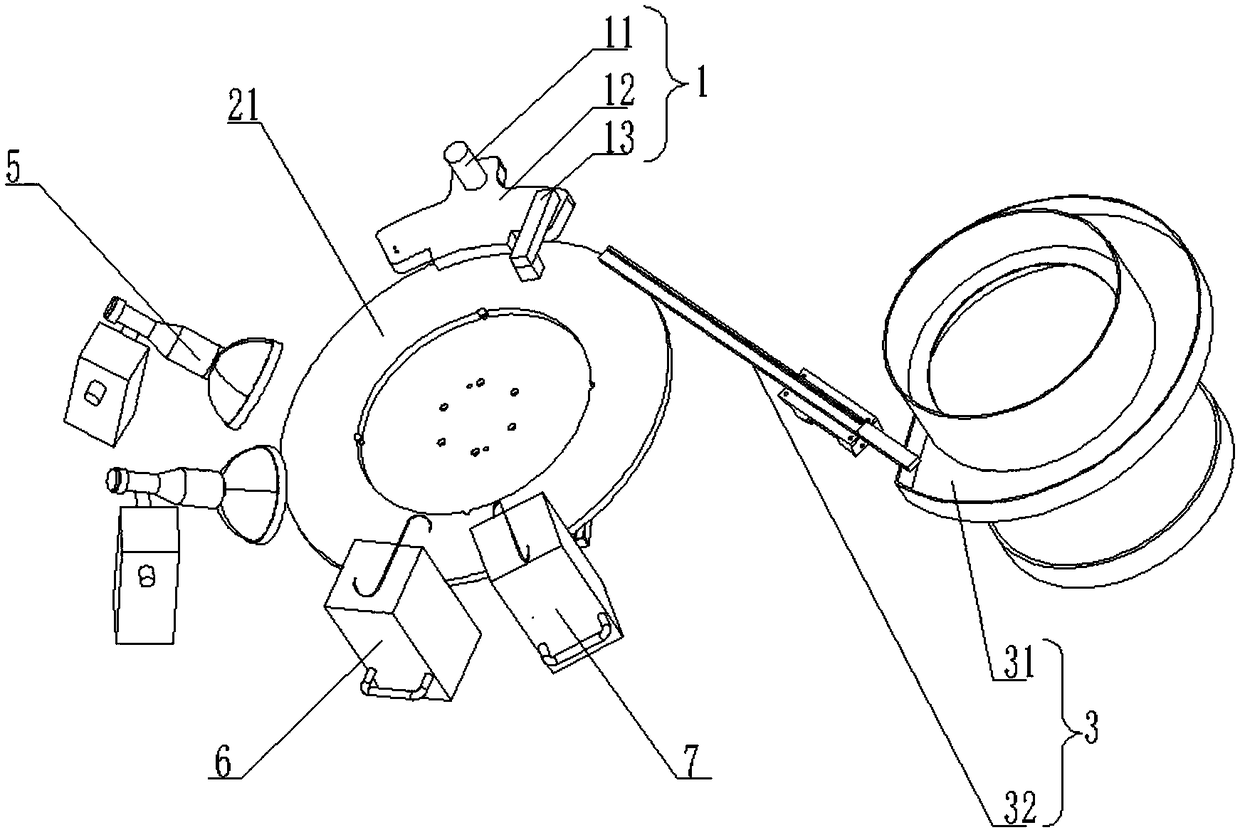

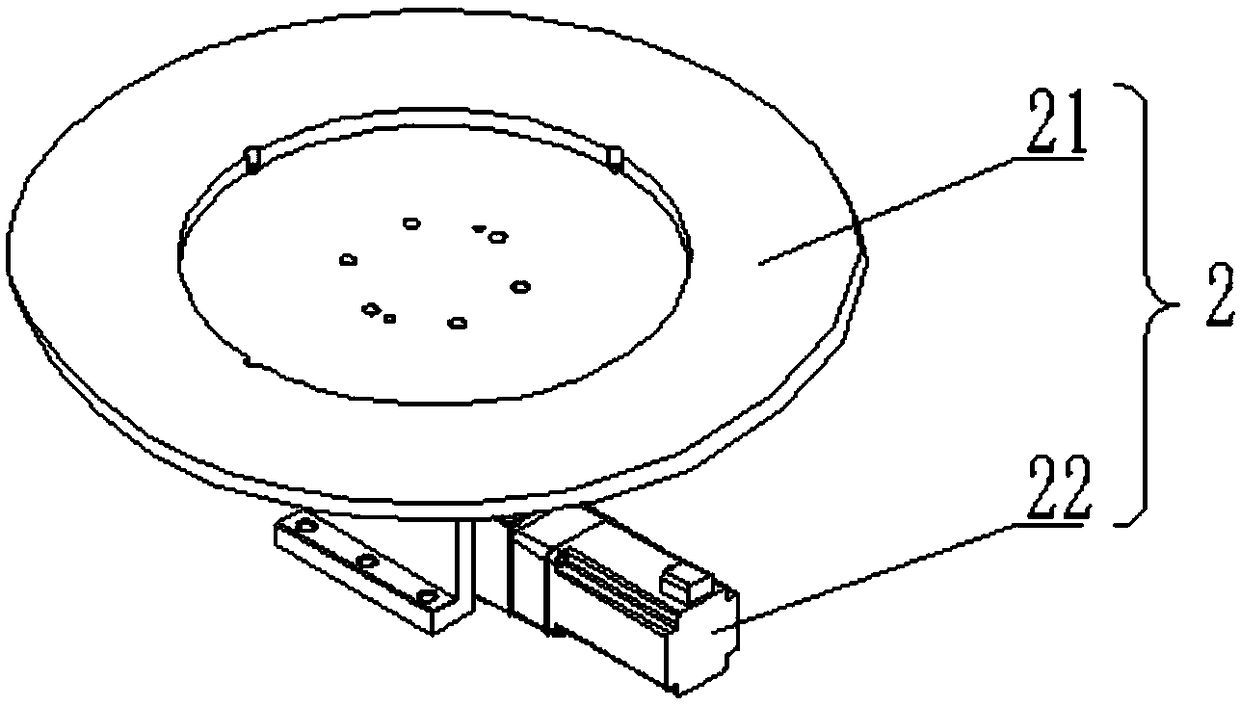

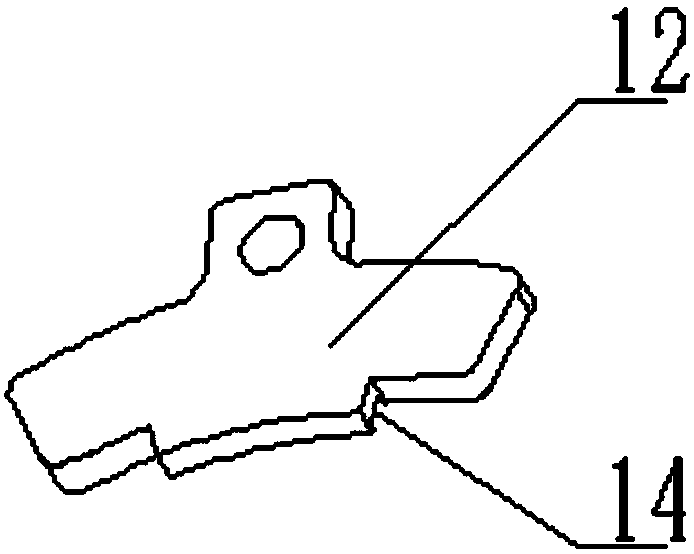

[0038] See Figure 1 to Figure 6 , the present invention has feeding station, detection station, sorting station and the turntable 21 that workpiece passes through feeding station, detection station and sorting station successively, and turntable 21 is driven to rotate by motor 22, and described feeding worker A discharge pipe 32 for transporting the workpiece to the turntable 21 is fixed on the position, and an L-shaped groove 321 for fixing the moving path of the workpiece is provided on the discharge pipe 32. The feeding station is provided with a vibrating plate 31, and the discharge One end of the tube 32 corresponds to the discharge port of the vibrating plate 31, and the other end is arranged above the turntable 21. A video recording device 5 for recording the shape of the workpiece is provided on the detection station, and the video recording device 5 is fixedly arranged on the turntable. The outside of 21, video-recording device 5 comprises a telecentric lens and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com