White tea cake-pressing device

A technology of white tea and steamed tea, which is applied in tea processing before extraction, etc., can solve the problems of inability to guarantee the quality of tea products, high workshop temperature, and inability to form tea leaves, so as to achieve uniform and stable tea product quality, lower workshop room temperature and humidity, and product quality Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

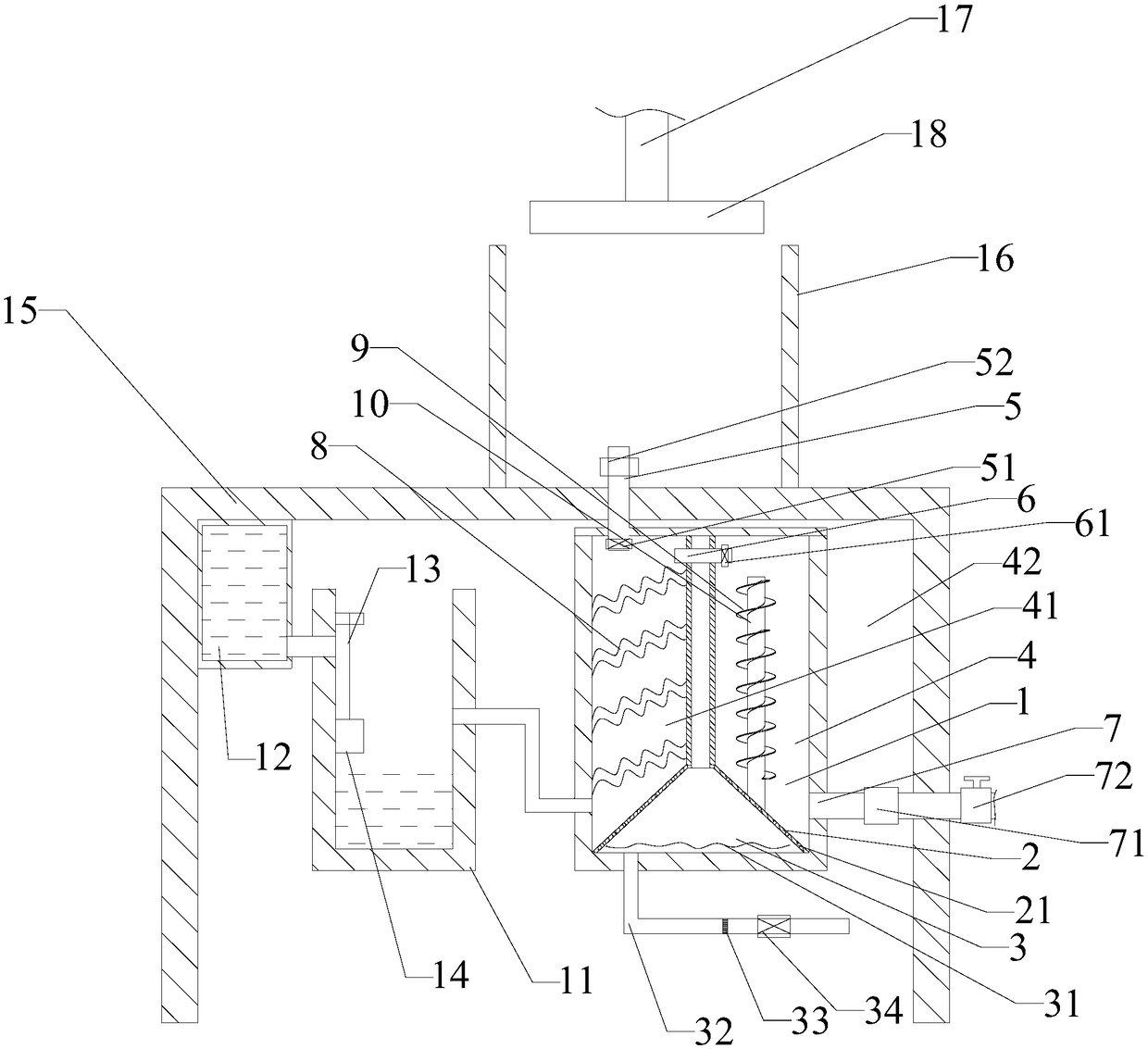

[0036] A white tea cake pressing device, comprising a steam boiler 11, a gas-liquid separator 1, a tea steaming device 16, a condensed water filter 33 and a steam trap 34, the steam boiler communicates with the gas-liquid separator through a pipeline, the The gas-liquid separator is connected with the tea steaming device through a pipeline;

[0037] The lower end of the gas-liquid separator 1 is provided with a conical hydrophobic cover 2, and a plurality of water leakage holes 21 are provided on the hydrophobic cover 2, and the area below the hydrophobic cover 2 is a water storage cavity 3, and the storage A heating wire 31 is provided in the water chamber 3, and the area above the hydrophobic cover 2 is a separation chamber 4 for gas-liquid separation;

[0038] The separation chamber 4 is divided into a first separation chamber 41 and a second separation chamber 42 by a partition plate, and the second separation chamber 42 is arranged on one side of the first separation cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com