Pull-down and roll-up type solar greenhouse roller shutter device and using method

A technology for solar greenhouses and roller blinds, which is applied in the directions of greenhouse cultivation, botanical equipment and methods, and applications, can solve the problems of reducing the structure and operation reliability of the roller blind device, and the uneven stress, so as to avoid the phenomenon of rope disorder, Avoid the effect of uneven force and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

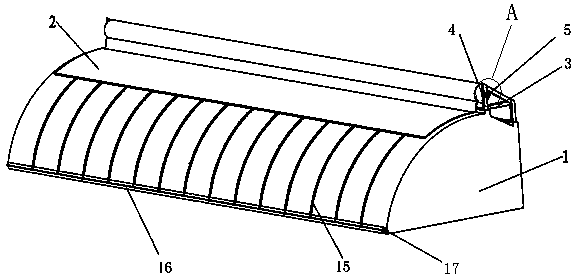

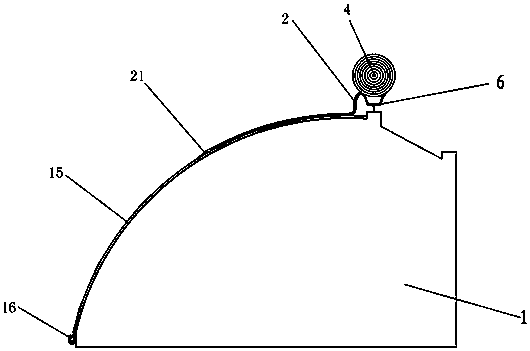

[0024] See Figure 1-Figure 7 , a pull-down and roll-up solar greenhouse roller blind device, comprising a main body of a greenhouse 1 and a thermal insulation quilt 2, a support frame 3 is arranged above the main body of the greenhouse 1, and a roller blind shaft 4 and a deceleration motor I5 are arranged on the support frame 3 to reduce the speed. The motor I5 drives the shutter shaft 4 to rotate, the support frame 3 is placed at the left and right ends of the main body of the greenhouse 1, and the support frame 3 and the shutter shaft 4 are connected by bearings; the material of the shutter shaft 4 is steel pipe; the support The frame 3 is welded to a square pipe;

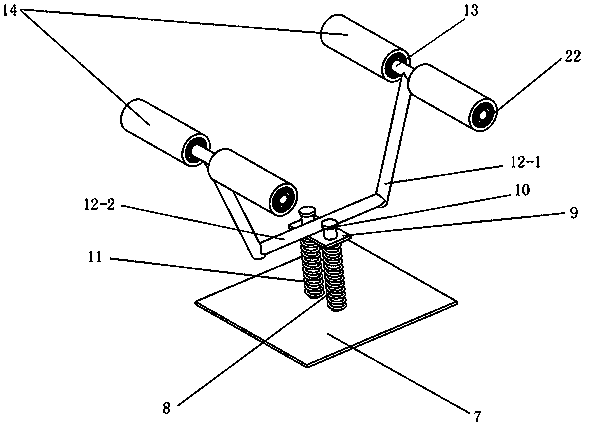

[0025] Above the main body of the greenhouse 1, there are multiple auxiliary bearing devices 6 directly below the shutter shaft 4, and the heat preservation quilt 2 wrapped around the shutter shaft 4 is placed on a plurality of auxiliary bearing devices 6, and the auxiliary bearing devices 6 include embedded ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com