Rotor speed monitoring processor

A rotor speed and processor technology, applied to devices using electric/magnetic methods, can solve problems such as inconsistent parameter values, signal load impedance mismatch, and complex wiring on the aircraft, so as to reduce operating costs and maintenance workload. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail, please refer to Figure 1 to Figure 3 .

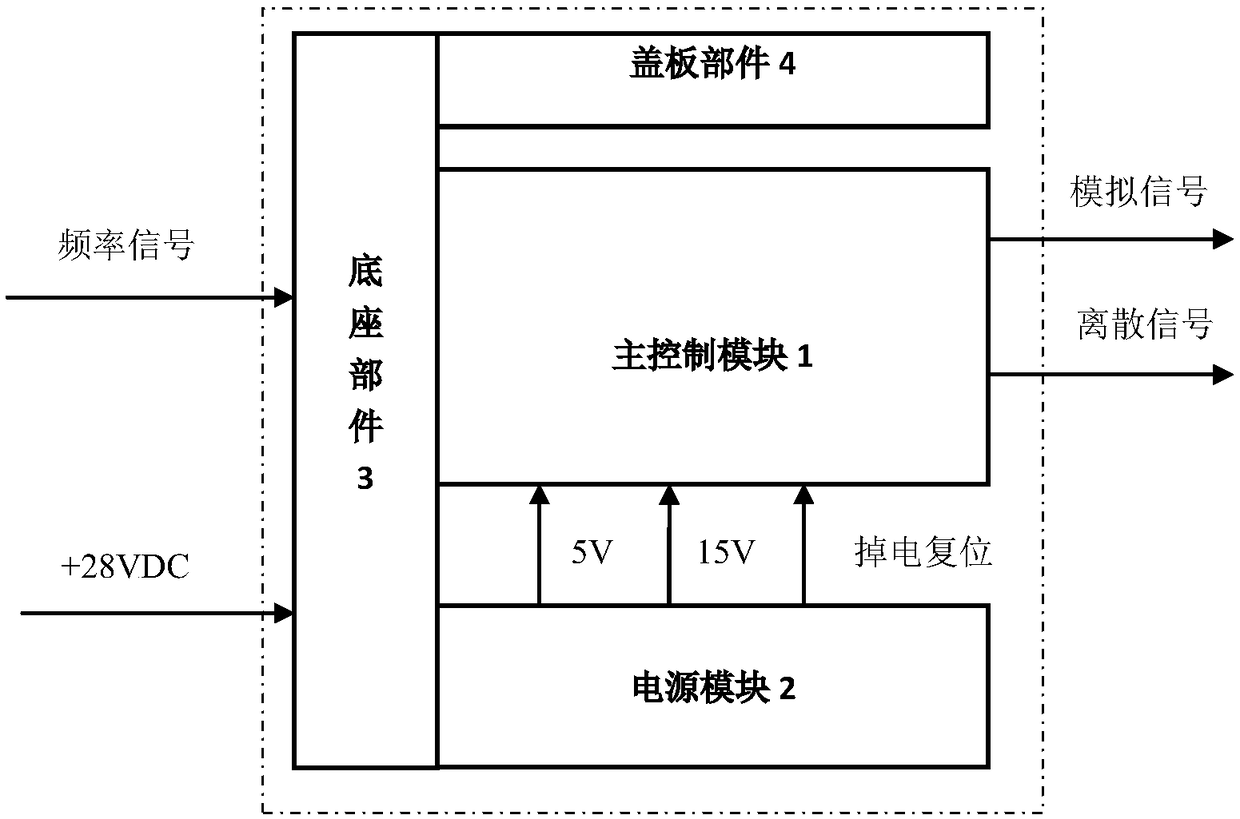

[0027] Such as figure 1 As shown, the rotor speed monitoring processor is composed of a main control module 1 , a power module 2 , a base part 3 and a cover part 4 .

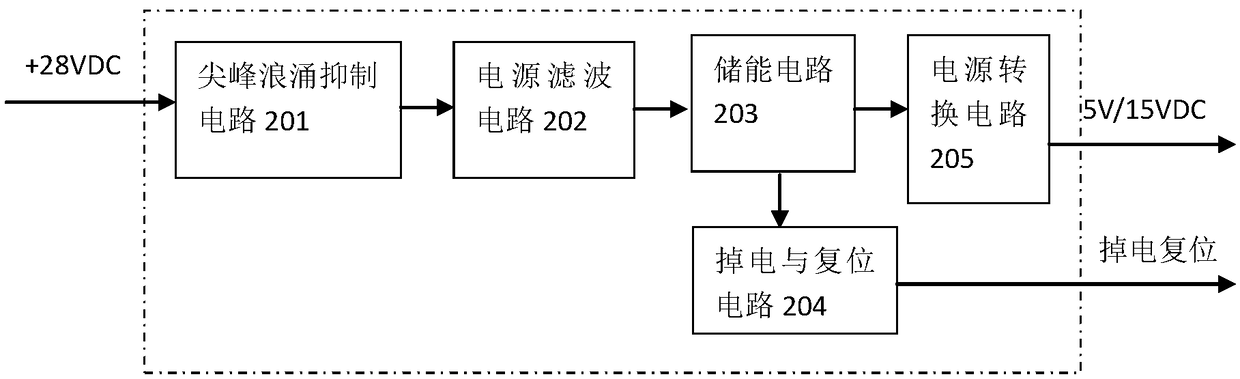

[0028] Such as figure 2 As shown, the main control module 1 includes a rotational speed interface circuit 101 , a discrete output drive circuit 102 , a frequency-voltage conversion circuit 103 , a DC output circuit 104 , a rotational speed comparison circuit 105 and a CPLD control circuit 106 . Wherein, the CPLD control circuit 106 is respectively connected with the rotational speed interface circuit 101, the discrete output drive circuit 102, the frequency-voltage conversion circuit 103 and the rotational speed comparison circuit 105; the rotational speed interface circuit converts the frequency signal into a square wave and outputs it to the CPLD control circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com