Gelation time measuring device and testing method

A technology of gelation time and measuring device, which is applied in the investigation phase/state change and other directions, can solve the problems of inability to automatically test the gelation time, different conditions for ending the timing, and great influence on the test results, so as to improve the measurement efficiency. , The effect of improving the measurement accuracy and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

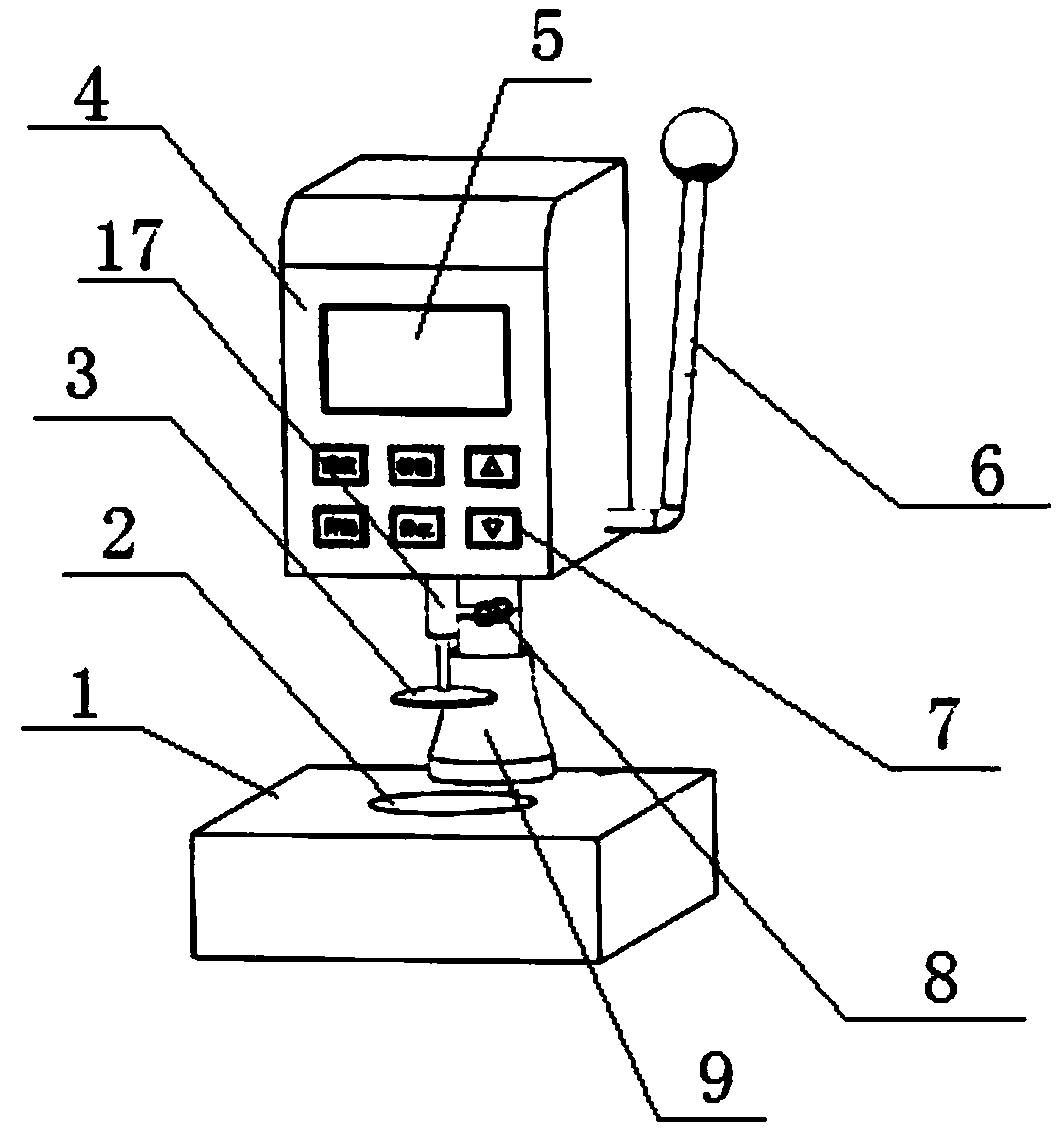

[0026] Embodiment 1, with reference to Figure 1-3 , a gelation time measuring device, comprising a base 1 and a test machine head, a column 9 is arranged behind the base 1, and a lifting mechanism for controlling the vertical movement of the test machine head is provided on the column 9;

[0027] Described test head comprises casing 4 and test head 3, is provided with the main motor that drives test head 3 to rotate in the casing 4, and test head 3 is contained on the output shaft of main motor, and test head 3 is equipped with on the base 1. The matching heating plate 2, the surface roughness of the heating plate 2 and the test head 3 is N10, the hardness is HRC60, and the casing 4 is provided with a control module for detecting the torque change of the main motor rotation to detect the curing degree of the sample;

[0028] The test head 3 is disc-shaped, and the center of the disc-shaped test head 3 is provided with a central rod inserted in the test head connecting rod 17....

Embodiment 2

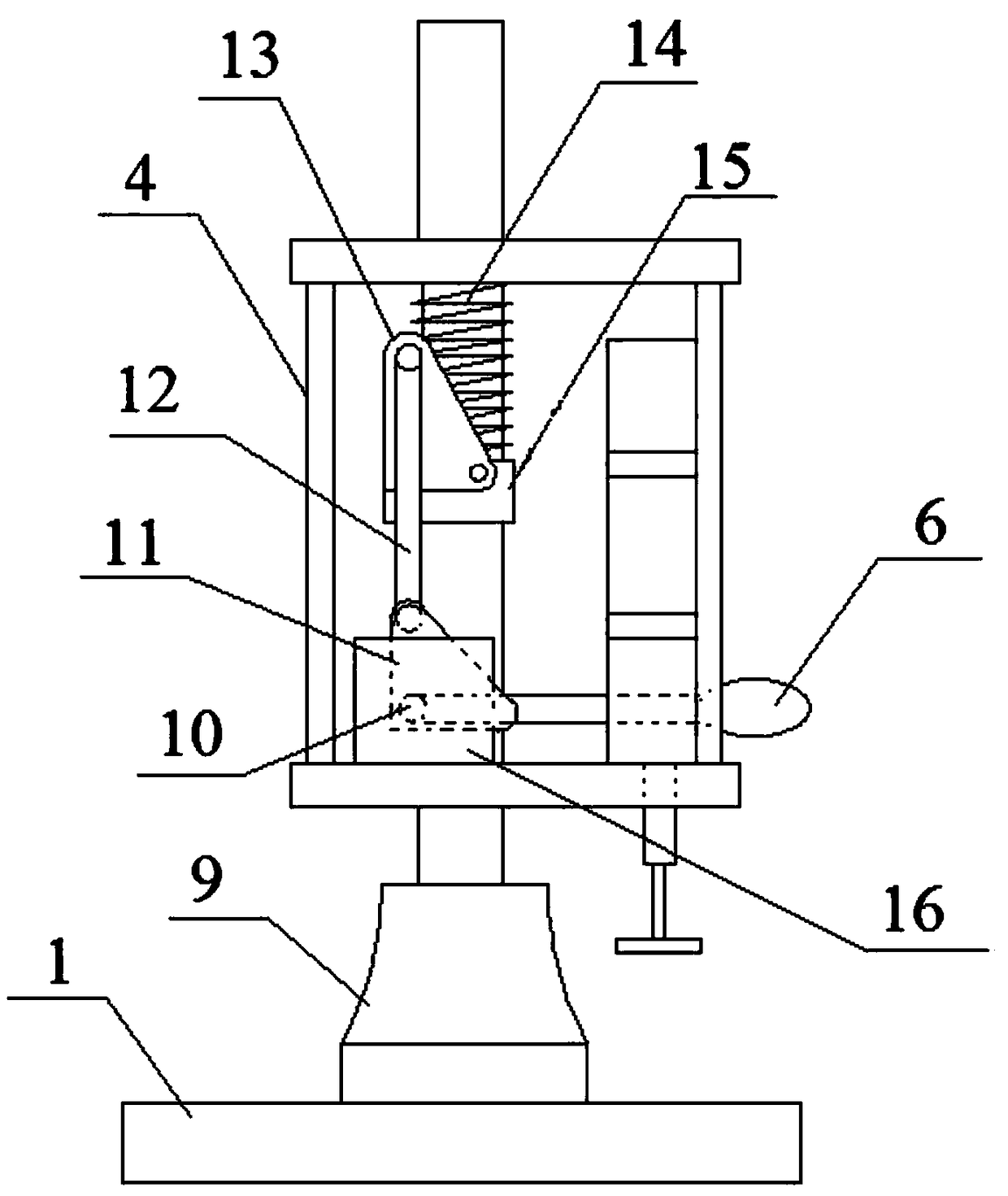

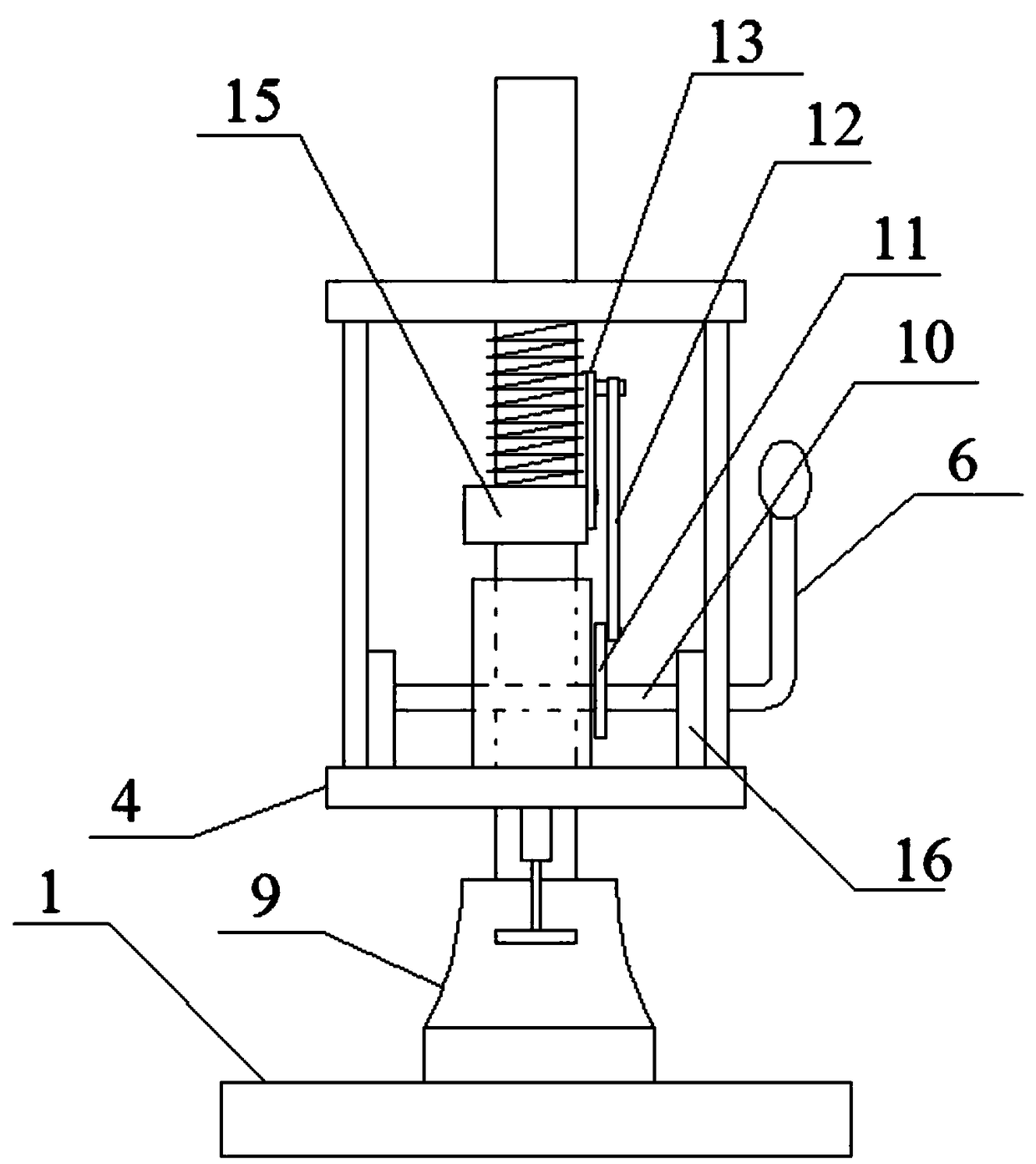

[0029] Embodiment 2, the gelation time measuring device described in Embodiment 1, the described lifting mechanism includes a fixed seat 15 mounted on the column 9, a traction mechanism is provided between the fixed seat 15 and the bottom of the casing 4, and the fixed seat 15 and the column 9 between the top of the casing 4 is equipped with a spring 14 for resetting the test machine head. 13 is hinged, and the lower end of the traction arm 12 is hinged with a lower triangular block 11, and the lower triangular block 11 is connected with the bearing seat 16 located at the bottom of the casing 4 through the horizontal rotating shaft 10.

Embodiment 3

[0030] Embodiment 3, the gelation time measuring device described in Embodiment 1-2, the handle 6 that drives the horizontal rotating shaft 10 to rotate is provided on the said casing 4;

[0031] The lower hinged end of the traction arm 12 is located on one of the corners of the lower triangular block, the horizontal rotating shaft 10 is installed on the other corner of the lower triangular block, and the upper triangular block is mounted on the fixed seat 15 by a bearing pin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com