Hanging system guide rail

A suspension system and guide rail technology, applied in the field of clothing production, can solve the problems of easy shaking and easy falling of down jackets, and achieve the effects of small footprint, reduced efficiency and short length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

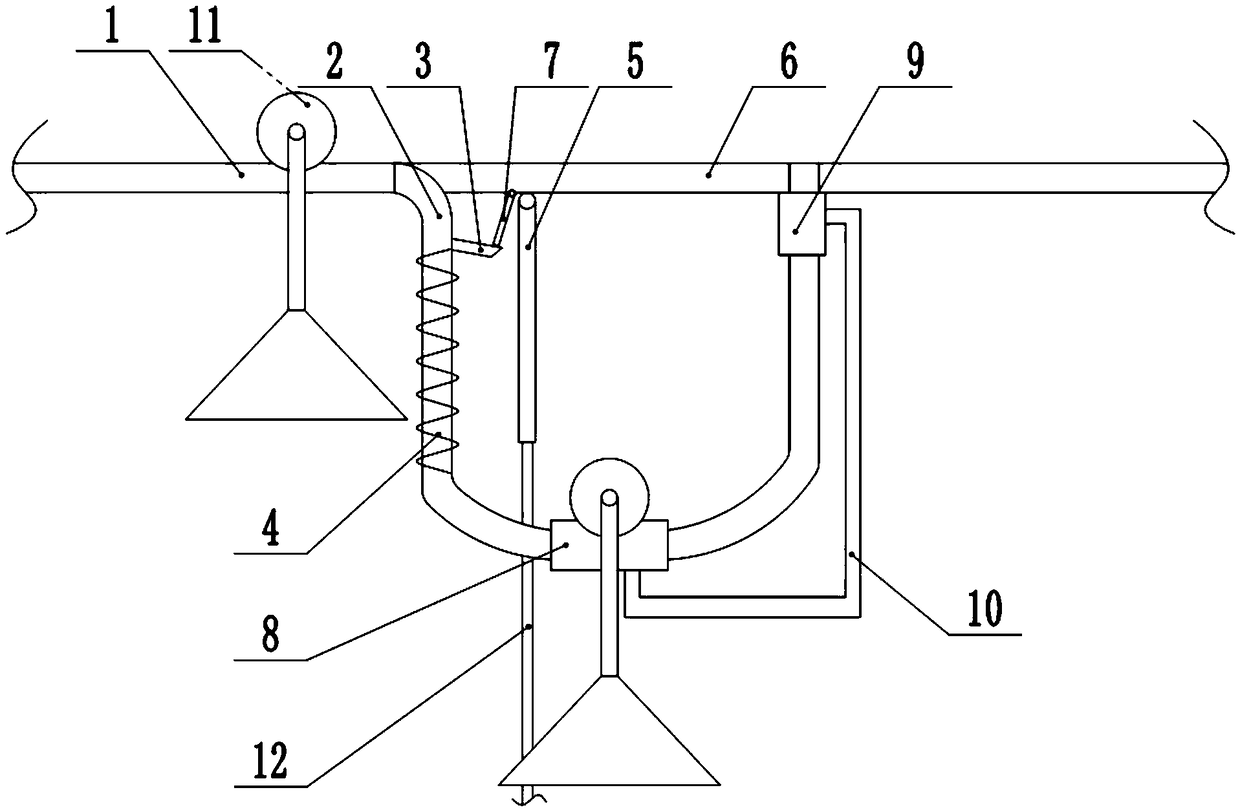

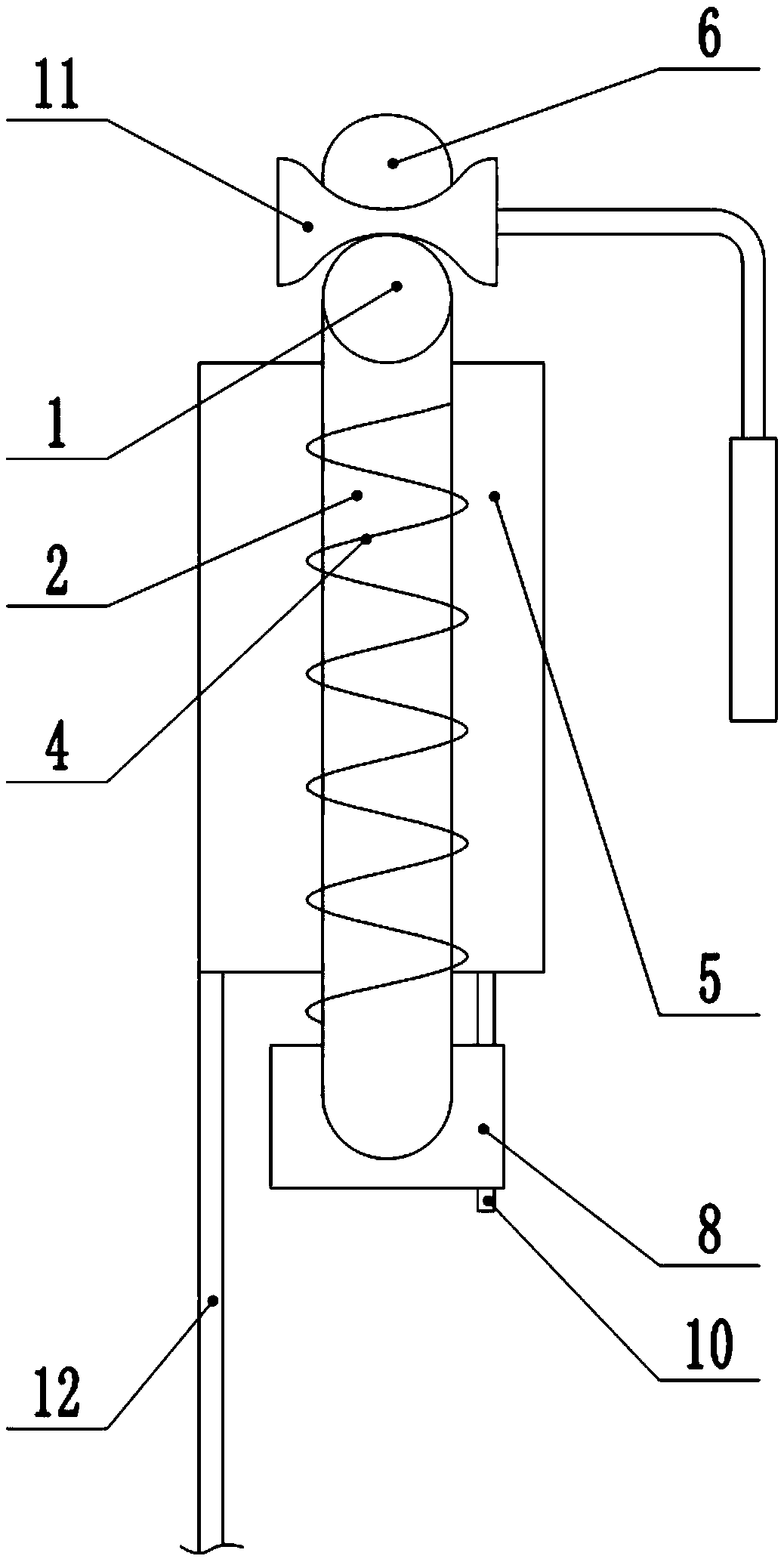

[0026] The reference signs in the drawings of the description include: conveying guide rail 1, station guide rail 2, inclined plate 3, spring 4, baffle plate 5, track changing guide rail 6, blade 7, buffer air bag 8, support air bag 9, pipe 10, roller 11, pole 12.

[0027] The embodiment is basically as attached figure 1 and image 3 Shown:

[0028] A suspension system guide rail, including several conveying guide rails 1, U-shaped station guide rails 2 are welded between adjacent conveying guide rails 1, a spring 4 is welded to the left end of the bottom of the station guide rail 2, and the spring 4 is vertically wound around the station On the guide rail 2, the top of the spring 4 is welded with an inclined plate 3 slidingly connected to the station guide rail 2, and the right end of the inclined plate 3 is in contact with a baffle 5, which is fixed on the ground through a pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com