Anti-radiation garment fabric

A technology of anti-radiation and anti-radiation layer, which is applied in the field of anti-radiation fabrics, can solve the problems of airtightness, unsatisfactory anti-radiation effect, uncomfortable wearing, etc., achieve high comfort, excellent oil-proof function, and reduce repeated pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

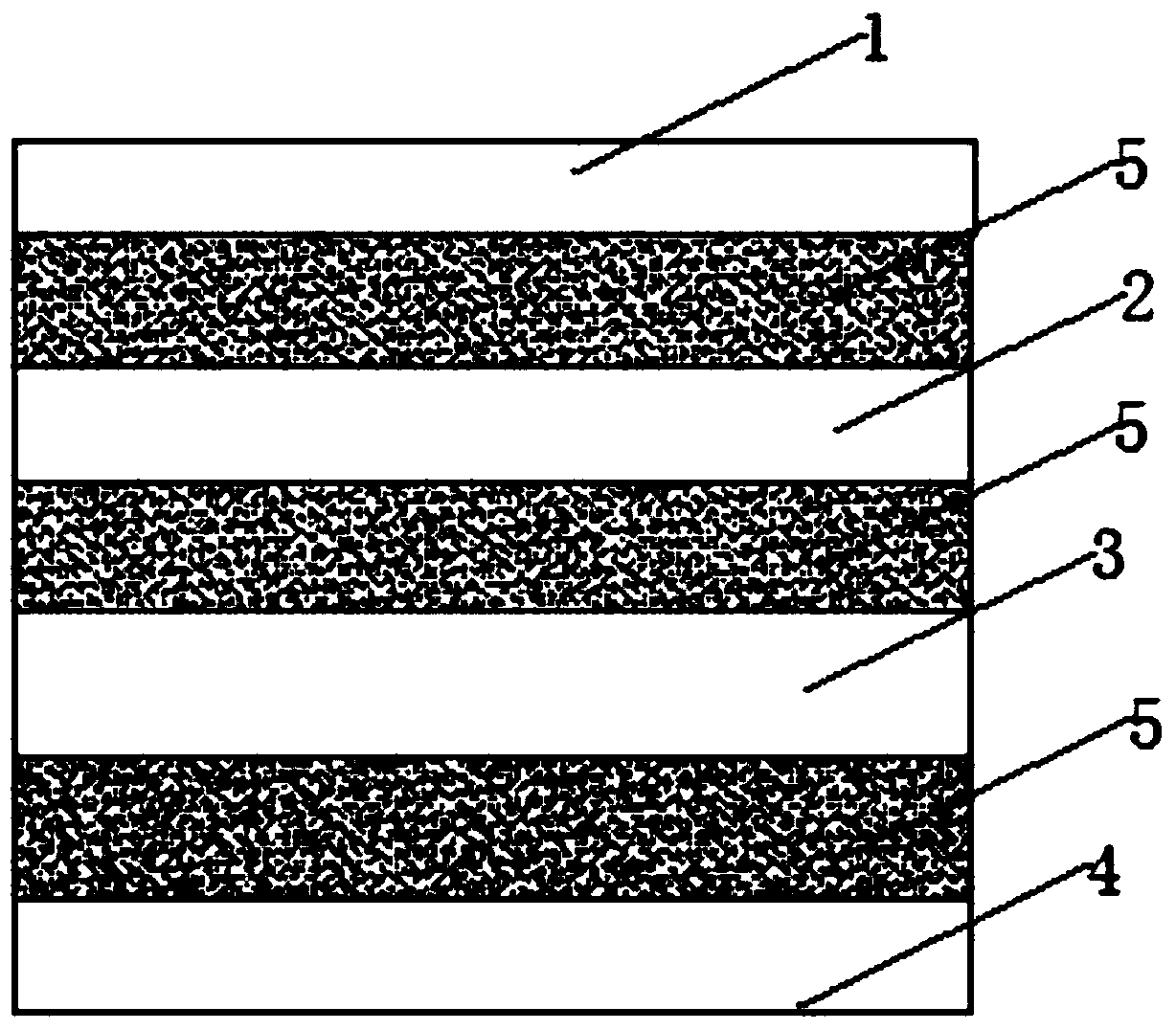

[0027] A kind of anti-radiation clothing fabric, comprises E-PTFE film layer 1, anti-radiation layer 2, knitted fabric layer 3, high temperature resistant layer 4 and bonding layer 5; The knot layer 5 is connected; the radiation protection layer 2 and the knitted fabric layer 3 are connected by an adhesive layer 5; the knitted fabric layer 3 and the high temperature resistant layer 4 are connected by an adhesive layer 5;

[0028] Wherein, the adhesive layer 5 includes an adhesive, and the adhesive includes the following raw materials in parts by weight: 10 parts of polyethylene oxide, 2 parts of auxiliary adhesive, 1.8 parts of defoaming agent and 20 parts of deionized water.

[0029] Specifically, the auxiliary binder is a mixture of styrene-butadiene rubber, polytetrafluoroethylene, and sodium carboxymethyl cellulose.

[0030] Specifically, the defoamer is a mixture of ethanol, ethylene glycol and propylene glycol.

[0031] Specifically, the preparation method of the binder...

Embodiment 2

[0042] A kind of anti-radiation clothing fabric, comprises E-PTFE film layer 1, anti-radiation layer 2, knitted fabric layer 3, high temperature resistant layer 4 and bonding layer 5; The knot layer 5 is connected; the radiation protection layer 2 and the knitted fabric layer 3 are connected by an adhesive layer 5; the knitted fabric layer 3 and the high temperature resistant layer 4 are connected by an adhesive layer 5;

[0043] Wherein, the adhesive layer 5 includes an adhesive, and the adhesive includes the following raw materials in parts by weight: 35 parts of polyethylene oxide, 5 parts of auxiliary adhesive, 3.5 parts of defoaming agent and 30 parts of deionized water.

[0044] Specifically, the auxiliary binder is a mixture of styrene-butadiene rubber, polytetrafluoroethylene, and sodium carboxymethyl cellulose.

[0045] Specifically, the defoamer is a mixture of ethanol, ethylene glycol and propylene glycol.

[0046] Specifically, the preparation method of the binder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com