Preparation method of dried nectarines

A nectarine and drying technology, which is applied to the functions of food ingredients, food preservation, and fruit and vegetable preservation, etc., can solve the problems of nutrient loss and low nutrient content, and achieve the effect of avoiding loss, rich nutrition, and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

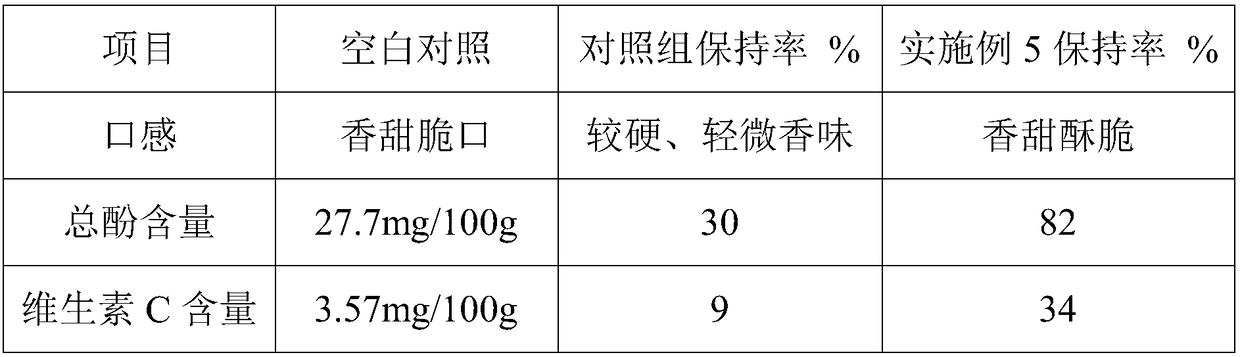

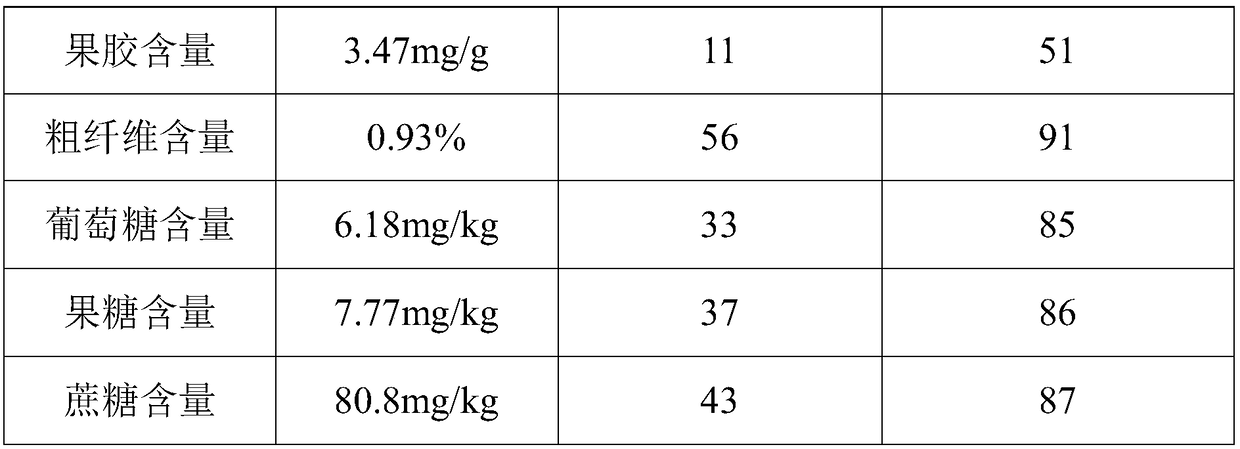

Examples

Embodiment 1

[0017] A method for preparing dried nectarines, comprising the following steps: taking nectarine slices and immersing them in a color-protecting agent solution, soaking them, taking out the nectarine slices and then immersing them in xylitol-milk aqueous solution, soaking them, then freeze-drying in vacuum, and finally changing the temperature and pressing The dried nectarines were obtained by differential expansion and drying.

Embodiment 2

[0019] A method for preparing dried nectarines, comprising the steps of: washing the nectarines with water, soaking the nectarines in an aqueous solution of 0.05 wt% citric acid for 4 minutes, removing the pits and slicing to obtain nectarine slices with a thickness of 5-6mm, and taking the nectarine slices Immerse in the color-protecting agent solution, soak for 30 minutes, take out the nectarine slices and immerse them in the xylitol-milk aqueous solution, soak for 6.5 hours, then adjust the temperature to -10°C, freeze and vacuum-dry until the water content of the nectarine slices is 30wt%, Finally, dried nectarines were obtained by puffing and drying with variable temperature and pressure difference. The puffing temperature was 70°C, the puffing pressure was 0.3MPa, the evacuation temperature was 50°C, the stagnation time was 7min, and the evacuation time was 2.8h.

Embodiment 3

[0021] A method for preparing dried nectarines, comprising the steps of: washing the nectarines with water, soaking the nectarines in an aqueous solution of 0.07 wt% citric acid for 3 minutes, removing the pits and slicing them into slices to obtain nectarine slices with a thickness of 5-6 mm, and taking the nectarine slices Immerse in the color-protecting agent solution, soak for 40min, take out the nectarine slices and then immerse in the xylitol-milk aqueous solution, soak for 5.5h, then adjust the temperature to -15°C, freeze and vacuum-dry until the water content of the nectarine slices is 25wt%, Finally, dried nectarines are obtained by puffing and drying with variable temperature and pressure difference. The puffing temperature of puffing and drying with variable temperature and pressure difference is 75°C, the puffing pressure is 0.25MPa, the evacuation temperature is 55°C, the stagnation time is 5min, the evacuation time is 3.2h, and the color is preserved. The agent s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com