High-temperature-resistant flame-retardant cable

A flame retardant cable, high temperature resistance technology, used in insulated cables, cables, power cables with shielding/conducting layers, etc., can solve the problems of poor high temperature resistance, unsatisfactory flame retardant effect, etc. , the effect of protecting other equipment and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the invention product will be further described in detail below in conjunction with the embodiments and accompanying drawings.

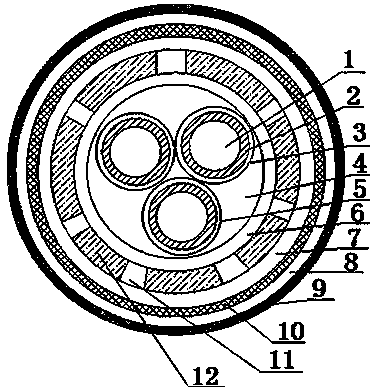

[0023] Such as figure 1 As shown, a high-temperature-resistant flame-retardant cable includes several cable cores 1, and the outside of the cable cores 1 is wrapped with a PLA layer 2 and a first shielding layer 3 in turn, and the first shielding layer 3 is provided with upper and lower corresponding settings. The fireproof cladding plate 4 is provided with accommodating groove 5 inside the fireproof cladding plate 4 correspondingly arranged up and down, the cable core 1 is placed in the accommodating groove 5, and the outer side of the fireproof cladding plate 4 is wrapped with The second shielding layer 6, the outer side of the second shielding layer 6 is wrapped with a halogen-free flame-retardant TPU layer 7, and the outer doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com