Manufacturing process of mud whistle sound chamber

A technique for producing craft and whistle sounds, which is applied to whistles, musical instruments, sounding instruments, etc. It can solve problems such as time-consuming, complex production process, and slow production speed, and achieve long service life, simple sound chamber production process, and loud sound quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

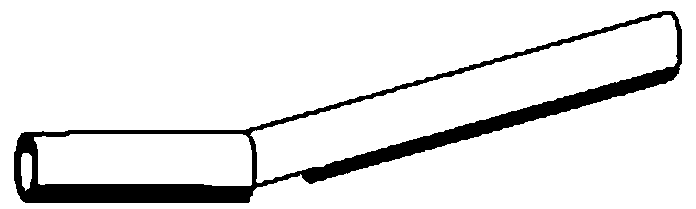

[0019] A manufacturing process of a mud whistle cavity, comprising the following steps:

[0020] S1. Complete the 3D modeling of the mud whistle sound cavity based on 3DMax, in which, the length of the front section of the air hole is 22mm; the length and width of the air hole are both 5mm; the length of the rear section of the air hole is 12mm; the wall thickness of the air hole is 1mm; °;

[0021] S2. Import the model into Maya software, "partition" into layer-by-layer sections, that is, slices, and drive the MakerbotReplicator printer to print layer by layer using PLA 1.75mm 3D lines. The printing sequence: the inner wall of the sound cavity → the sound of the sound cavity → the sound cavity Terminal port→sound cavity whistle→sound cavity outer wall;

[0022] S3. After the printing is completed, use a 3*140mm pointed round file to polish the inner wall, and a 3*140mm flat file to polish the outer wall, and remove the auxiliary support structure and burrs until the sound ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com