Portable rock mechanical experiment sample grinding machine

A rock mechanics, convenient technology, applied in the field of rock mechanics experiments, can solve the problems of short specimens, difficult to fix, increased constraints, increased use costs, etc., and achieves simple structure, strong adaptability to the use environment, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

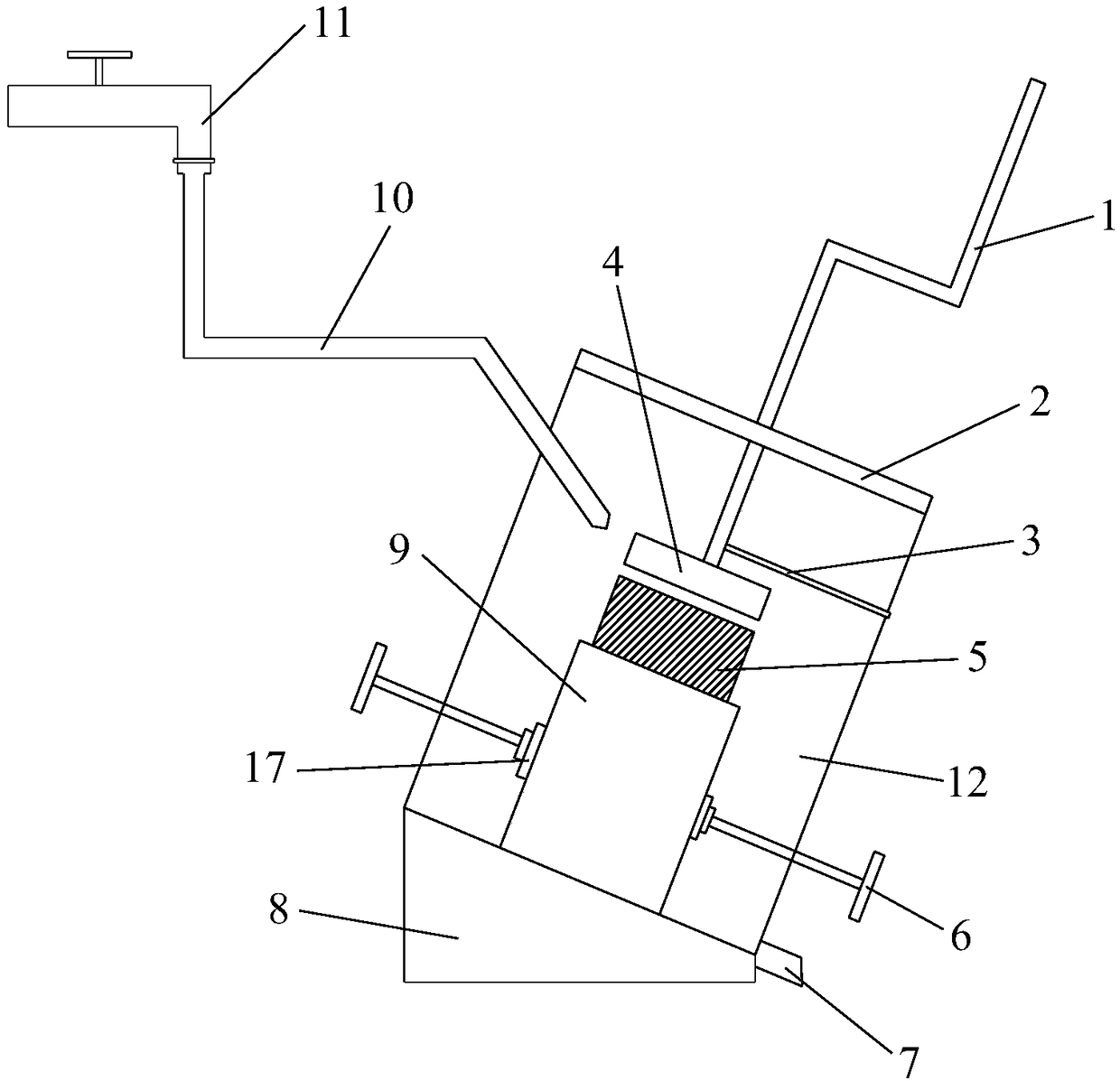

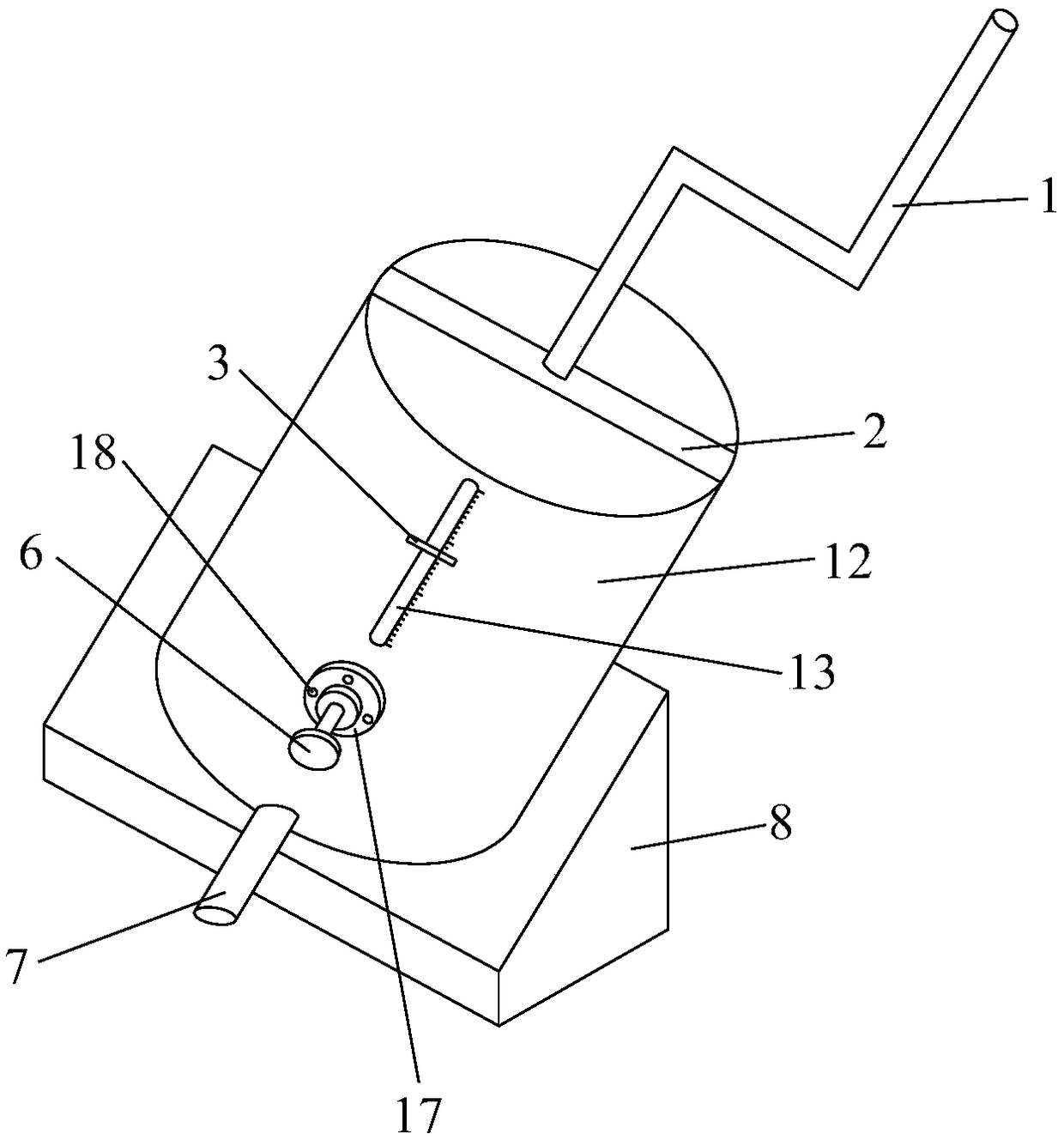

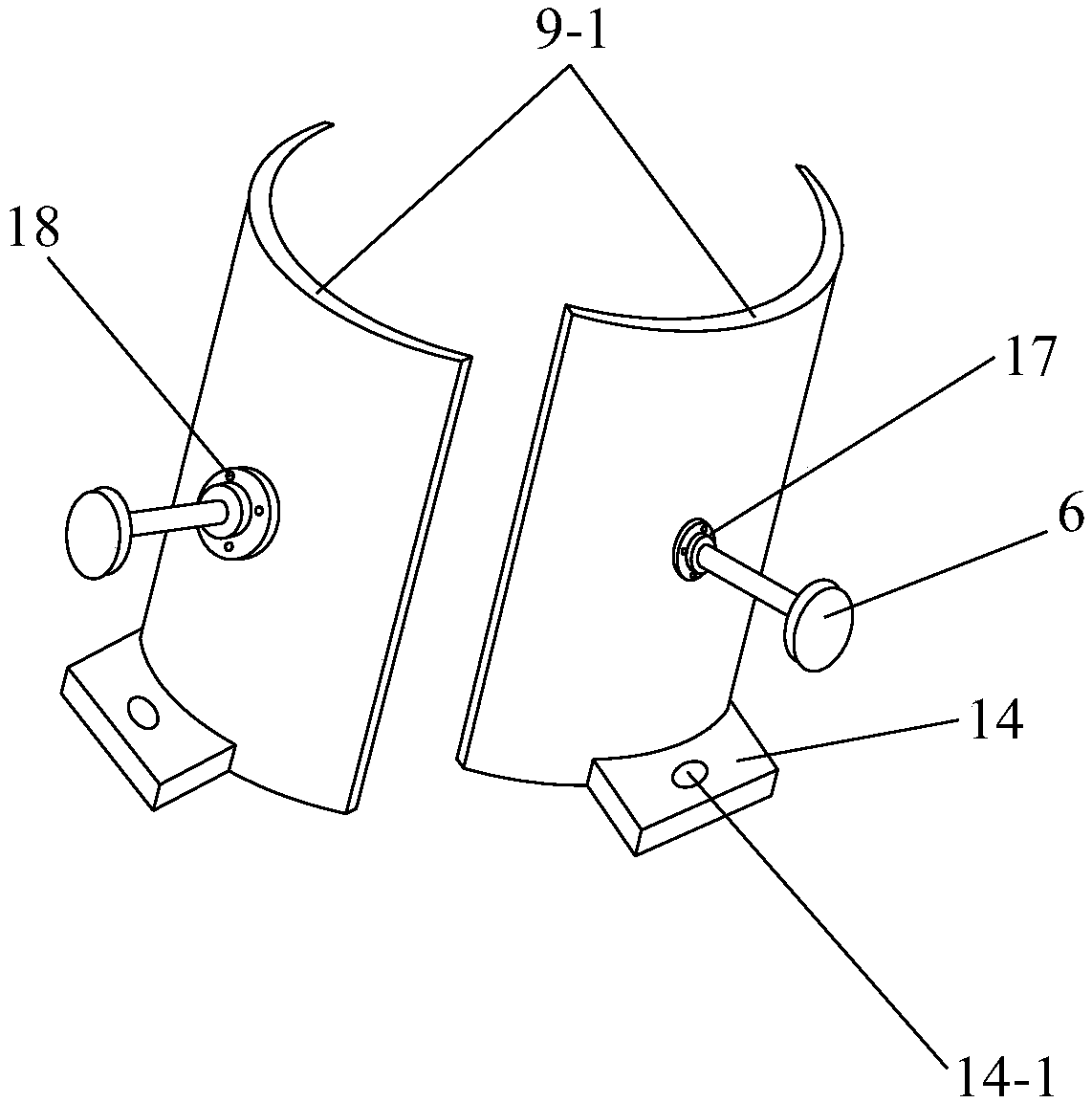

[0036] Such as figure 1 and figure 2As shown, the present invention includes a fixed frame, a sample fastening mechanism, a sample grinding mechanism and a sample watering mechanism, the sample fastening mechanism is arranged on the lower part of the fixed frame, and the sample grinding mechanism is arranged on the The upper part of the fixed frame, the test piece water spray mechanism is arranged on the side of the fixed frame, the fixed frame includes a base 8, a fixed cylinder 12 and a rocker support 2, and the base 8 is a top surface The wedge-shaped structure of the inclined surface, the fixed cylinder 12 is a cylindrical structure, the bottom of the fixed cylinder 12 is fixedly connected with the top of the base 8, and the rocker support 2 is installed on the top of the fixed cylinder 12, so The upper side of the fixed cylinder 12 is provided with a water inlet, the bottom of the fixed cylinder 12 is provided with a water outlet 7, and the fixed cylinder 12 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com