A mold structure for automatic shear gate of plastic pipe fittings

A plastic pipe fitting, automatic technology, applied in the direction of tubular items, household appliances, other household appliances, etc., can solve the problems of easily scratching the molding surface of the pipe fittings, increase the outer size of the mold, increase the cost, etc., to save costs and cut off the position. Stable and labor-saving assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

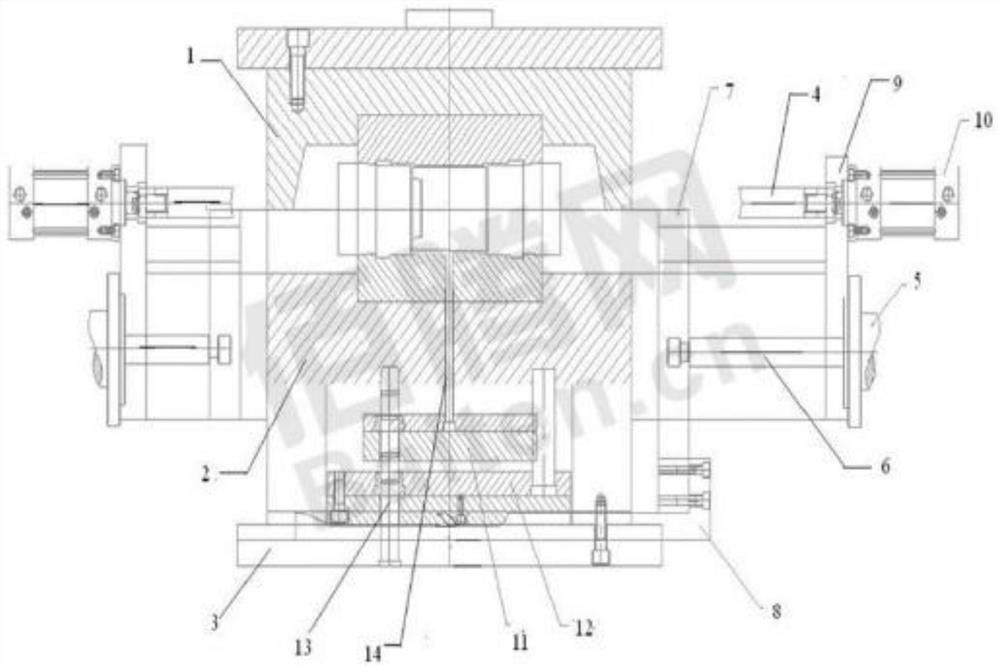

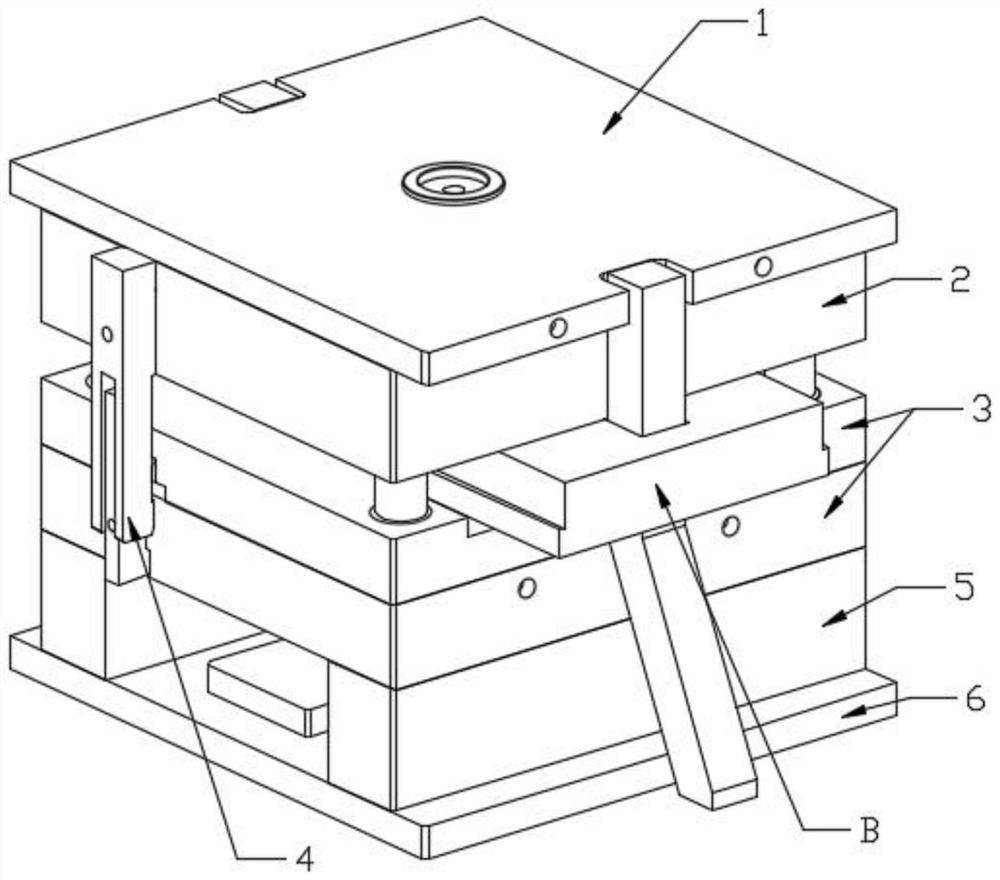

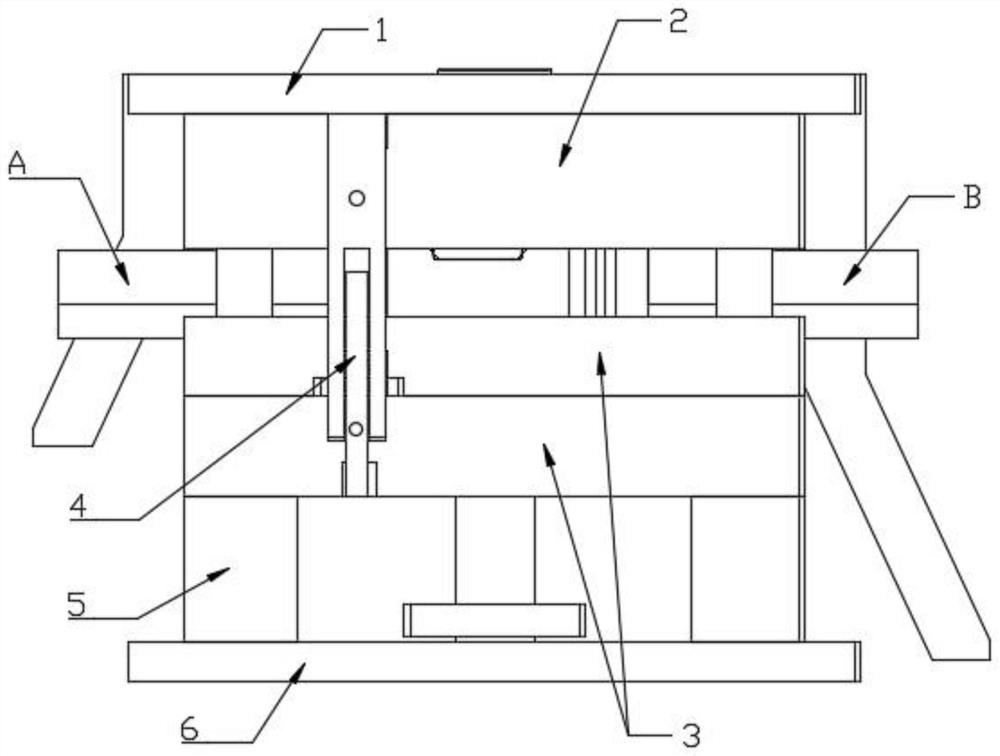

[0039] See Figure 2-6 The in-mold automatic shear gate mold structure of the plastic pipe fitting of the first embodiment of the present invention comprises: an upper double plate 1, a fixed mold 2, a movable mold 3, a core-pulling A and a core-pulling B which are slidably connected with the movable mold 3, Pull hook 4, die foot 5, lower double board 6.

[0040] The upper double plate 1 is connected and fixed with the fixed mold 2 . The movable mold 3 is connected and fixed with the lower double plate 6 through the mold foot 5 . The fixed mold 2 is fixed with a first bent pin 2A and a second bent pin 2B for respectively driving the core-pullin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com