Semi-automatic assembly equipment for wooden pallets

A semi-automated wooden pallet technology, which is applied in the direction of wood processing equipment, wooden veneer joints, manufacturing tools, etc., can solve the problems of poor strength of wooden pallets 7

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

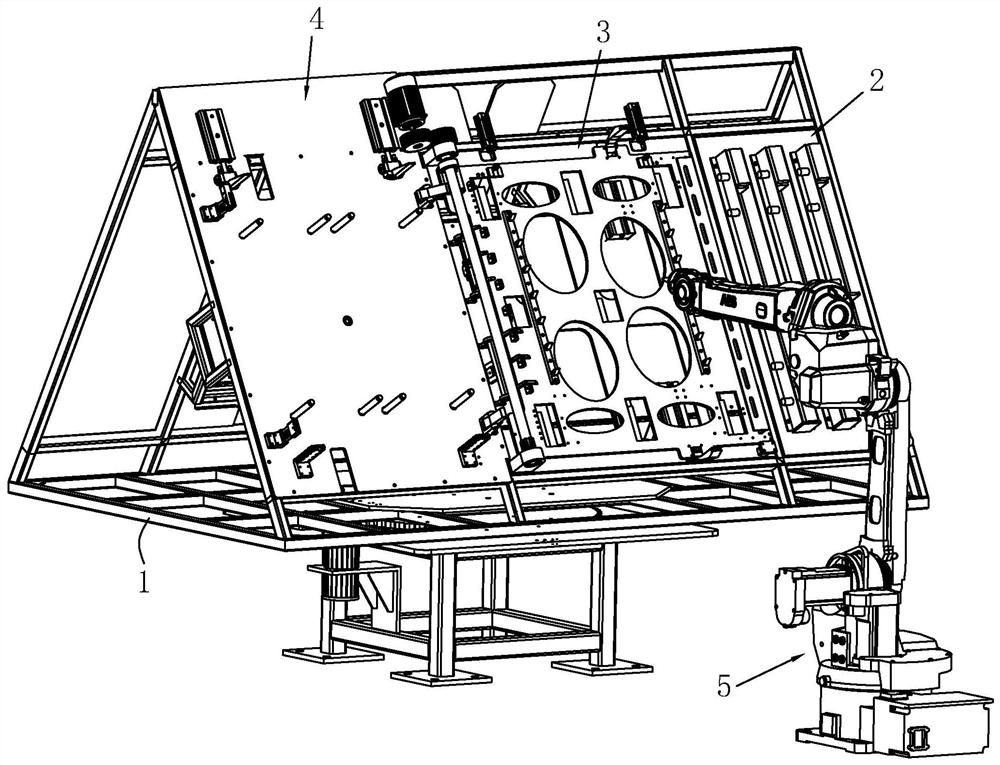

[0043] Such as figure 1 As shown, a wooden pallet semi-automatic assembly equipment includes a frame body 1. The cross section of the frame body 1 is arranged in a triangular shape. An assembly station 2, a second assembly station 3 and a third assembly station 4, the first assembly station 2, the second assembly station 3 and the third assembly station 4 are located on the same plane, and the side of the frame body 1 faces the first assembly station 2. A manipulator 5 is provided at the position where the second assembly station 3 and the third assembly station 4 are located. In this embodiment, by installing the nail gun on the manipulator 5, the manipulator 5 controls which nail gun is used for the first The wooden pallet 7 splicing parts on the assembly platform 2, the second assembly platform 3 and the third assembly platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com