A firefighting robot that closes a fire valve

A fire-fighting robot and valve technology, applied in the directions of manipulators, manufacturing tools, claw arms, etc., can solve the problems of complicated and difficult to observe the valve, unable to close the valve, difficult for personnel to approach, etc., achieve excellent fireproof and explosion-proof performance, shorten clamping time , Reliable performance of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

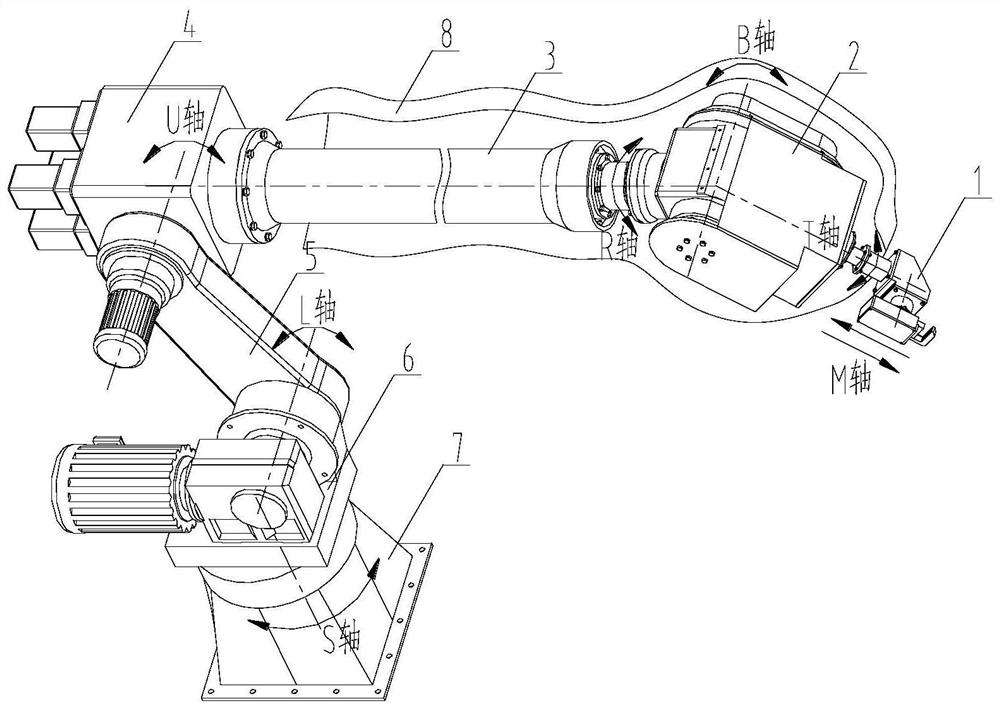

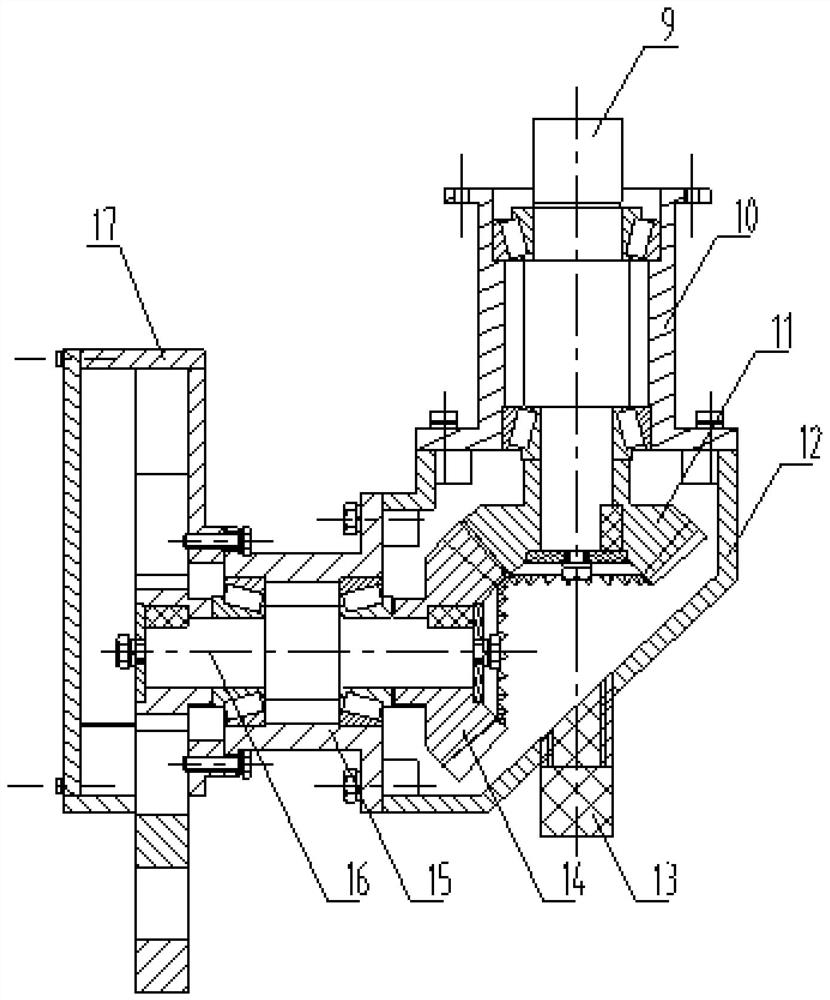

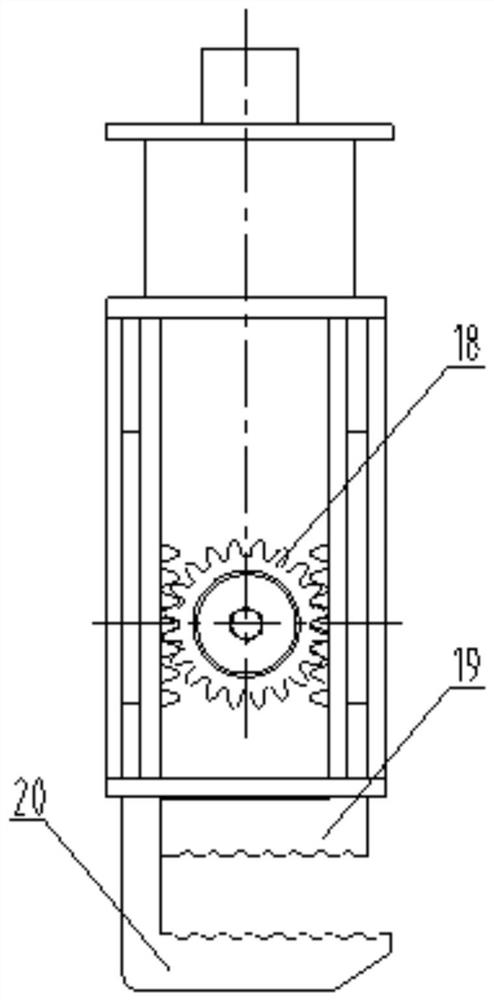

[0026] The invention is as figure 1 As shown, it mainly consists of an end effector 1, a wrist unit 2, an upper arm unit 3, an upper arm drive unit 4, a lower arm unit 5, a waist unit 6, a base 7, a high temperature protective suit 8, and the like. The end effector 1 realizes the opening and closing of the valve by clamping the valve handle and rotating around the center of the valve. The end effector 1 has two actions: rotating around the T axis and moving up and down along the M axis. The end effector 1 is connected with the wrist unit 2 by splines and bolts. The wrist unit 2 plays the role of transmitting the motion of the end effector 1 and adjusting the position of the end effector 1. The wrist unit 2 can drive the end effector 1 to rotate around the B axis and rotate around the R axis. The wrist unit 2 passes the spline. And bolts are connected with the upper arm unit 3 together. The upper arm unit 3 functions to transmit the motion of the end effector 1 and the wrist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com