Preparation method of carbon black doped liquid crystal microcapsules

A microcapsule and liquid crystal technology, applied in the fields of fine chemical industry and material science, can solve the problems of reduced color brightness, insufficient color, poor brightness of liquid crystal microcapsules, etc., and achieves the effects of improved brightness, simple operation and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

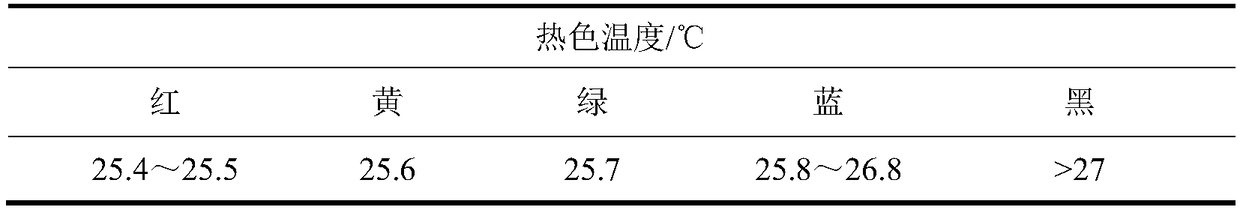

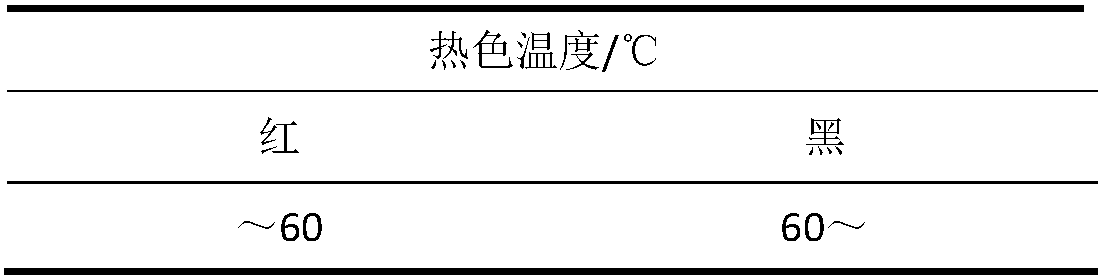

[0027] (1) Mix 3g of cholesteryl nonanoate and 7g of cholesteryl oleyl carbonate and heat until they are completely dissolved and become transparent. After stirring for 2 hours at this temperature, cool down until the mixed liquid crystal appears color or turbid, and then heat up to just Transparent, stirred at a constant temperature for 4 hours, added 0.02 g of carbon black modified with γ-aminopropyltriethoxysilane, and continued to stir at a constant temperature for 4 hours to obtain a liquid crystal mixture;

[0028] (2) Microencapsulation: Keep the liquid crystal mixture at a certain temperature and add it dropwise to the aqueous solution of gum arabic at the same temperature under the action of mechanical stirring, emulsify at a high speed to prepare a liquid crystal dispersion, and then slowly add the aqueous gelatin solution dropwise to obtain a liquid crystal reaction system , wherein the liquid crystal mixture accounts for 5% of the mass fraction of the liquid crystal...

Embodiment 2

[0033] (1) Mix 1g of cholesteryl propionate, 1.5g of cholesteryl oleate, 2g of cholesteryl benzoate, and 0.5g of cholesteryl ethyl carbonate and heat until just completely dissolved. After stirring for 2 hours at this temperature, After the temperature is lowered until the mixed liquid crystal is colored or turbid, the temperature is raised until it is just transparent, and stirred at a constant temperature for 4 hours, and 0.05 g of carbon black modified with γ-glycidyloxypropyltrimethoxysilane is added thereto, and the constant temperature is stirred for 4 hours. Obtain liquid crystal mixture;

[0034] (2) Microencapsulation: Keep the liquid crystal mixture at a certain temperature and add it dropwise to the gum arabic and dispersant aqueous solution at the same temperature under mechanical stirring, emulsify at a high speed, and prepare a liquid crystal dispersion, then slowly add the gelatin aqueous solution dropwise to obtain Liquid crystal reaction system, wherein the li...

Embodiment 3

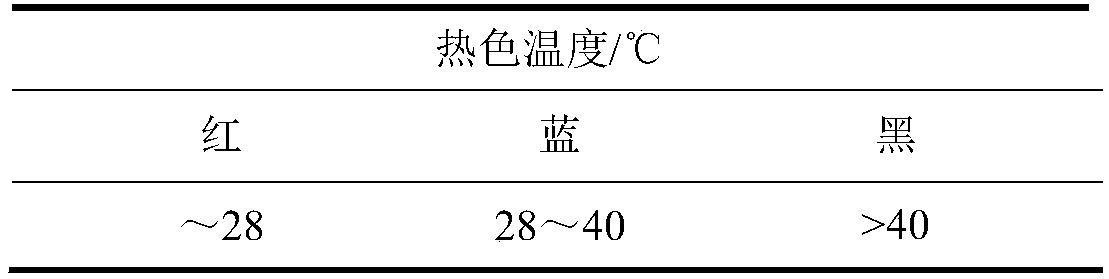

[0039] (1) Mix 3.8g of CB15 and 6.2g of E7 and heat until they are completely dissolved. After stirring at this temperature for 2 hours, cool down until the mixed liquid crystal appears color or turbid, then heat up to just transparent, stir at constant temperature for 4 hours, and add 0.05 g of carbon black modified with γ-glycidyl etheroxypropyltrimethoxysilane, and continued constant temperature stirring for 4 hours to obtain a liquid crystal mixture;

[0040] (2) Microencapsulation: Keep the liquid crystal mixture at a certain temperature and add it dropwise to the gum arabic and dispersant aqueous solution at the same temperature under mechanical stirring, emulsify at a high speed, and prepare a liquid crystal dispersion, then slowly add the gelatin aqueous solution dropwise to obtain Liquid crystal reaction system, wherein the liquid crystal mixture accounts for 10% of the mass fraction of the liquid crystal reaction system, gum arabic accounts for 5% of the mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com