Production method for tea-fragrant fish

A production method and technology for ayu, applied in the production field of ayu, can solve the problems of single tea flavor, inconsistent health concept, and high salt content, and achieve the effects of avoiding curling or deformation, improving sensory quality, and mild process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

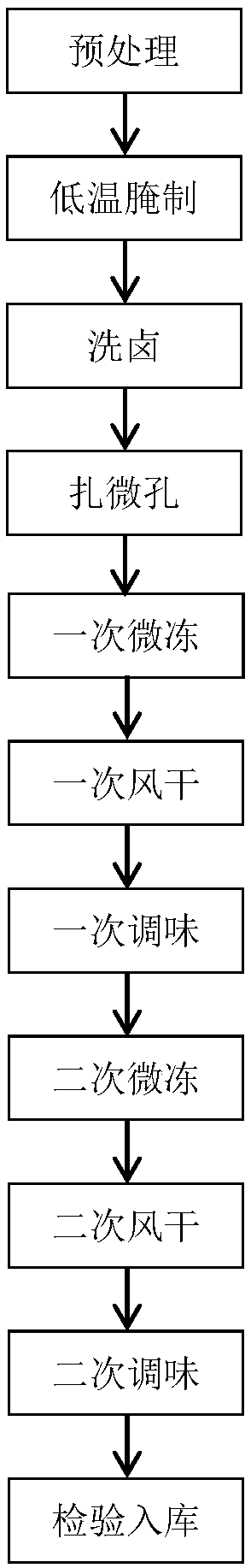

Image

Examples

Embodiment 1

[0033] A kind of production method of tea fragrant fish, comprises the steps:

[0034] (1) Pretreatment: Select fresh, live, pollution-free and disease-free raw fish, remove scales, gills, viscera and black film, wash with clean water, drain the surface water of the fish, and set aside;

[0035] (2) Low-temperature marinating: apply the marinade evenly on the surface of the fish body obtained in step (1), mix well, and marinate at a temperature of 2-10°C for 24-48 hours; For heavy objects, turn the tank up and down every 6-12 hours;

[0036] (3) Washing marinade: washing the fish body after low-temperature pickling with a mass concentration of 1% to 4% salt water, cleaning off the marinade on the surface, and then draining the surface water for subsequent use;

[0037] (4) Make microholes: the fish body obtained in step (3) is made into microholes with a diameter of 0.2 to 1 mm and a depth of 1 to 2 mm;

[0038] (5) One-time micro-freezing: place the belly of the fish body o...

Embodiment 2

[0046] A kind of production method of tea fragrant fish, comprises the steps:

[0047] (1) Pretreatment: Select fresh, live, pollution-free and disease-free raw fish, remove scales, gills, viscera and black film, wash with clean water, drain the surface water of the fish, and set aside;

[0048] The raw fish used in this example is Wuchang fish, with a size of 500-600g; mechanical scaling is used for descaling, and the stainless steel frame for collecting fish scales is put into the bottom of the scaling machine, the fish is put into the automatic descaling machine, and the machine is turned on. Then add an appropriate amount of water while rotating. The running time of the machine is about 30s. After the completion, open the door and throw all the fish bodies into the plastic basket; clean the fish bodies and remove the remaining fish scales with a wire brush, and then use Back-opening method, lay the fish body flat, with the back facing you, press the head with the left hand...

Embodiment 3

[0060] A kind of production method of tea fragrant fish, comprises the steps:

[0061] (1) Pretreatment: Select fresh, live, pollution-free and disease-free raw fish, remove scales, gills, viscera and black film, wash with clean water, drain the surface water of the fish, and set aside;

[0062] The raw fish used in this example is Wuchang fish, with a size of 500-600g; mechanical scaling is used for descaling, and the stainless steel frame for collecting fish scales is put into the bottom of the scaling machine, the fish is put into the automatic descaling machine, and the machine is turned on. Then add an appropriate amount of water while rotating. The running time of the machine is about 30s. After the completion, open the door and throw all the fish bodies into the plastic basket; clean the fish bodies and remove the remaining fish scales with a wire brush, and then use Back-opening method, lay the fish body flat, with the back facing you, press the head with the left hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com