Method, assistance system and 3d-printer for computer-aided design of objects for additive manufacturing

A 3D printer and additive manufacturing technology, applied in computer-aided design, general control systems, manufacturing aids, etc., can solve the problems of additional cost, not automatically including constraints, etc., to achieve the effect of interactive changes and less computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

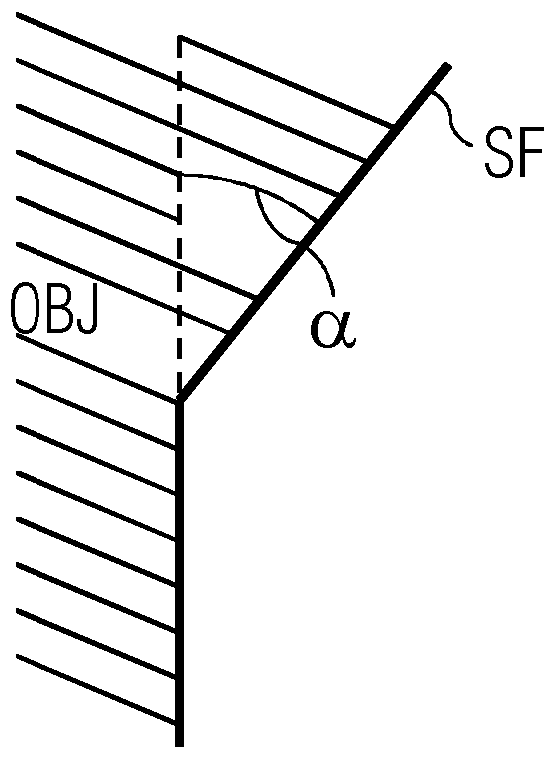

[0024] figure 1 An overhanging side SF of an object OBJ to be additively manufactured, for example to be printed by a 3D printer, is illustrated. Here, the angle with respect to the vertical line of the object surface SF is called an overhang angle α. As already mentioned above, if the overhang angle α is too large, it is possible to additionally install the support structure before printing and to remove the support structure again after printing. An overhang angle α of less than 45° is generally acceptable, while an overhang angle α greater than 45° may require the installation of additional support structures.

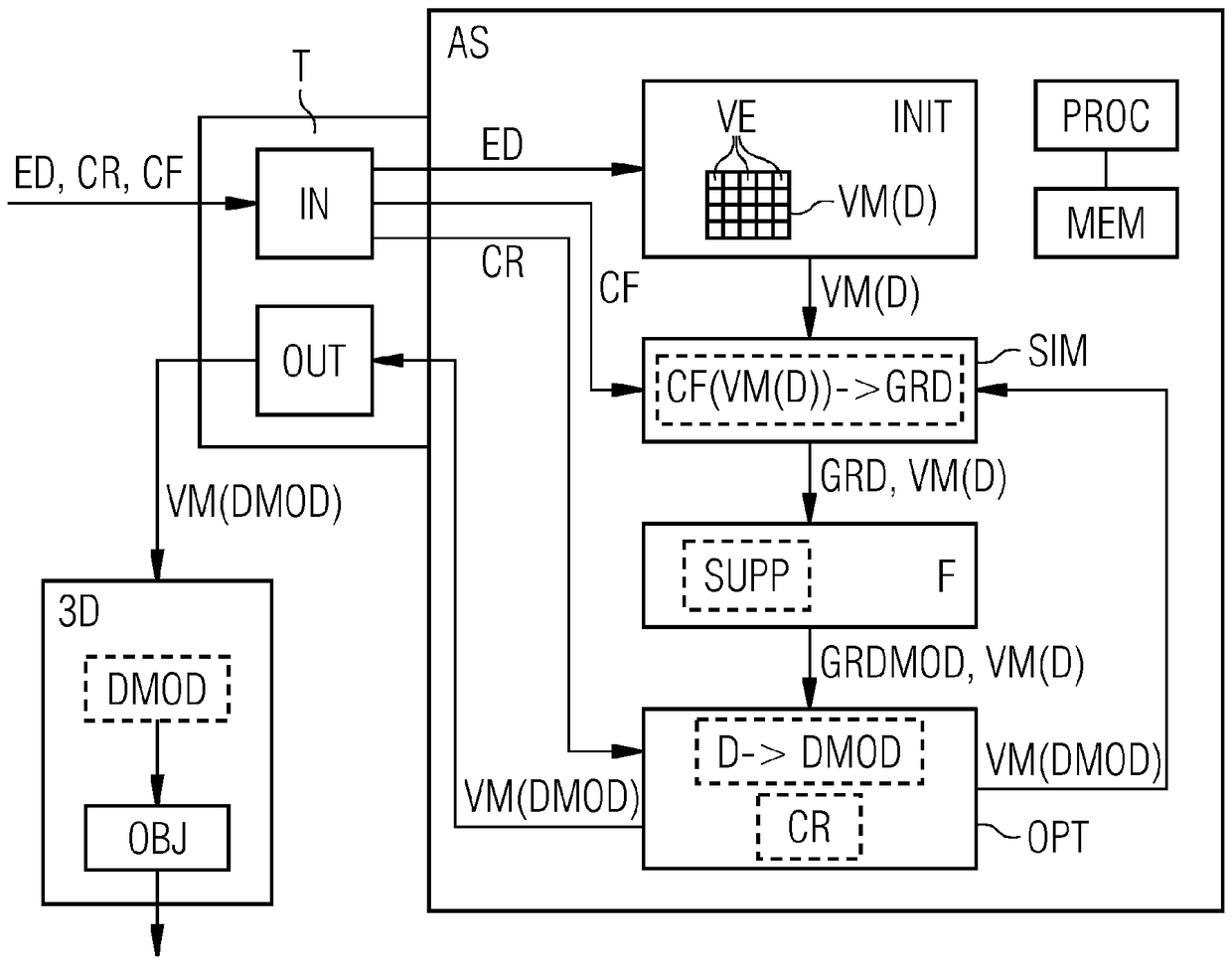

[0025] figure 2 An auxiliary system AS for designing an object OBJ to be additively manufactured and a 3D printer 3D for printing the designed object OBJ are shown. The assistance system AS has one or more processors PORC, which are configured to execute all method steps of the assistance system AS and / or to execute program commands for carrying out these method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com