Solenoid having inverse tapered armature for solenoid-actuated valve

A solenoid, armature technology, applied in the direction of electromagnets with armatures, valve operation/release devices, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

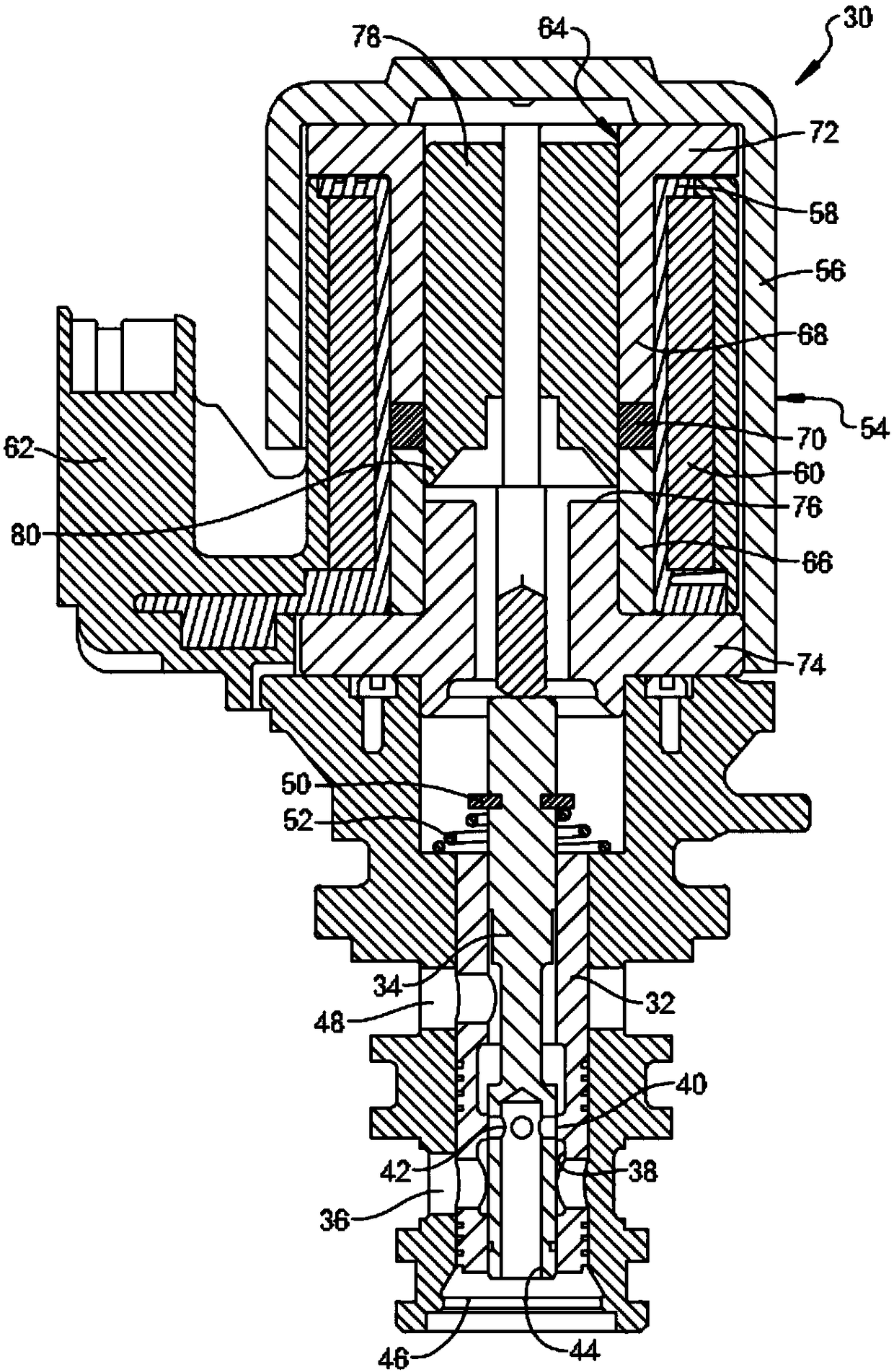

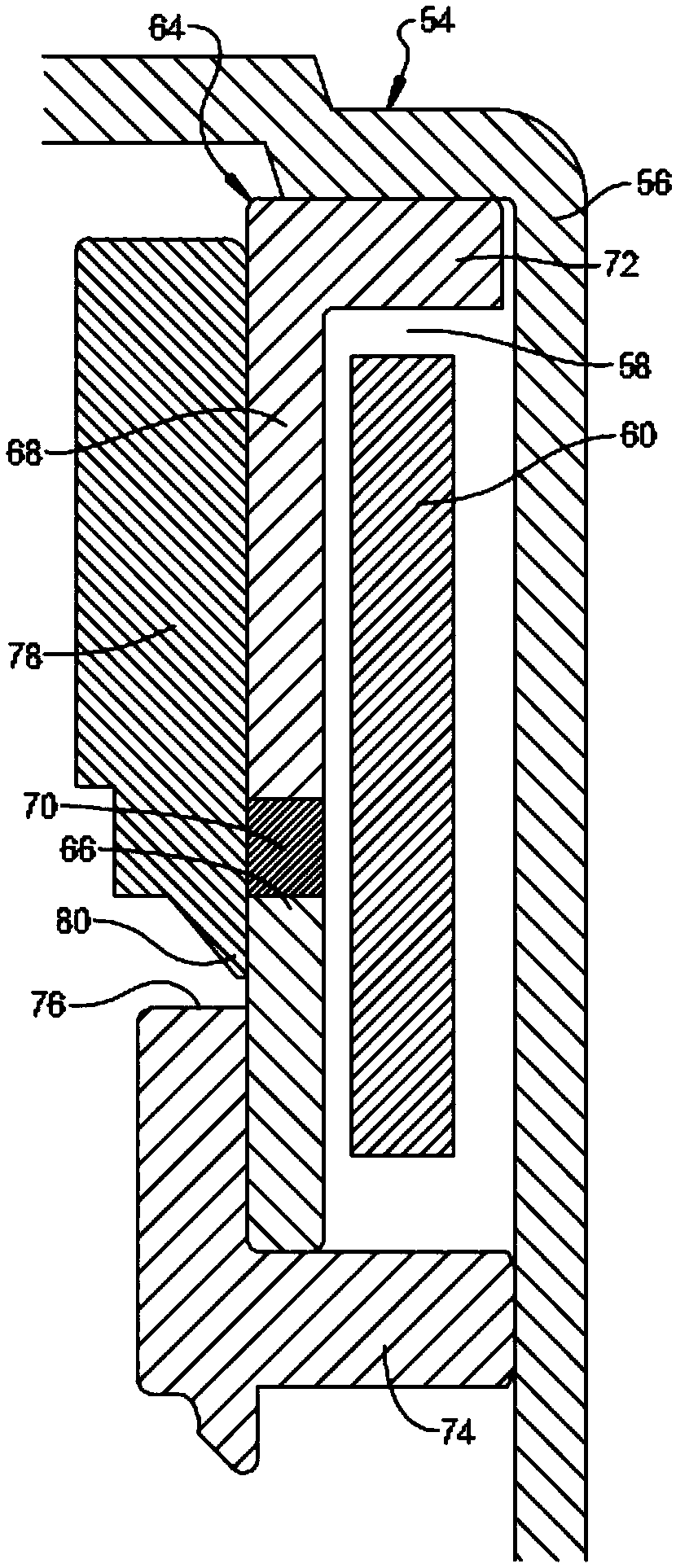

[0017] Referring now to the drawings, in which like reference numerals are used to refer to like structures unless otherwise indicated, a solenoid actuated valve 30 according to one embodiment of the present invention is figure 1 shown in , for use in conjunction with an automatic transmission (not shown) for a vehicle (not shown). The vehicle includes an engine (not shown) that cooperates with an automatic transmission. The engine produces rotational torque that is selectively transferred to an automatic transmission, which in turn transfers rotational torque to one or more wheels of the vehicle. It should be appreciated that the engine and / or automatic transmission may be of any suitable type, configured in any suitable manner sufficient to generate and transfer rotational torque to propel the vehicle, without departing from the scope of the present invention. It should also be appreciated that the solenoid actuated valve 30 may be used in any system such as a transfer case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com