Semiconductor structure and method of forming same

A semiconductor and wet etching technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problems that the performance of semiconductor devices needs to be improved, achieve the effect of improving performance and reliability, and avoiding the increase of process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It can be seen from the background art that the performance of semiconductor devices needs to be improved. Combining with a method of forming a semiconductor structure, the reason why its performance needs to be improved is analyzed.

[0019] Semiconductor devices are mainly divided into core (Core) devices and peripheral (I / O) devices (or called input / output devices) according to their functions. Usually, the operating voltage of peripheral devices is much higher than that of core devices. In order to prevent problems such as electrical breakdown, when the operating voltage of the device is higher, the thickness of the gate dielectric layer of the device is required to be thicker. Therefore, the thickness of the gate dielectric layer of peripheral devices is usually greater than that of the core device.

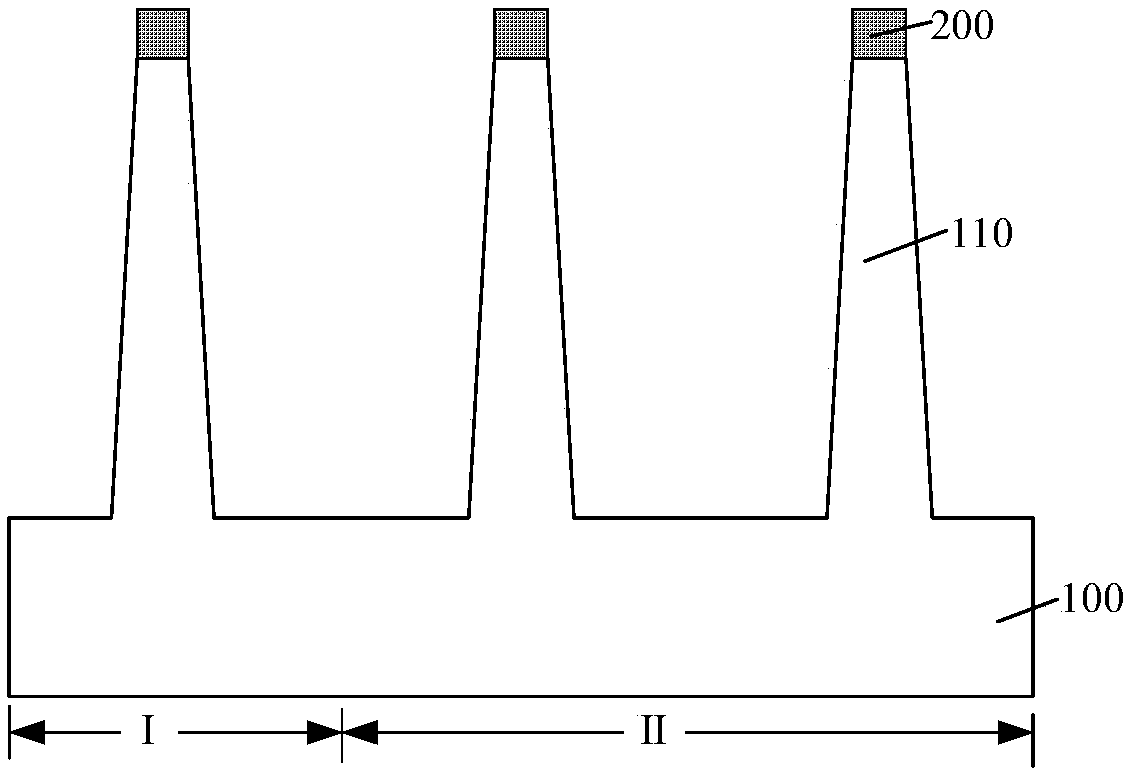

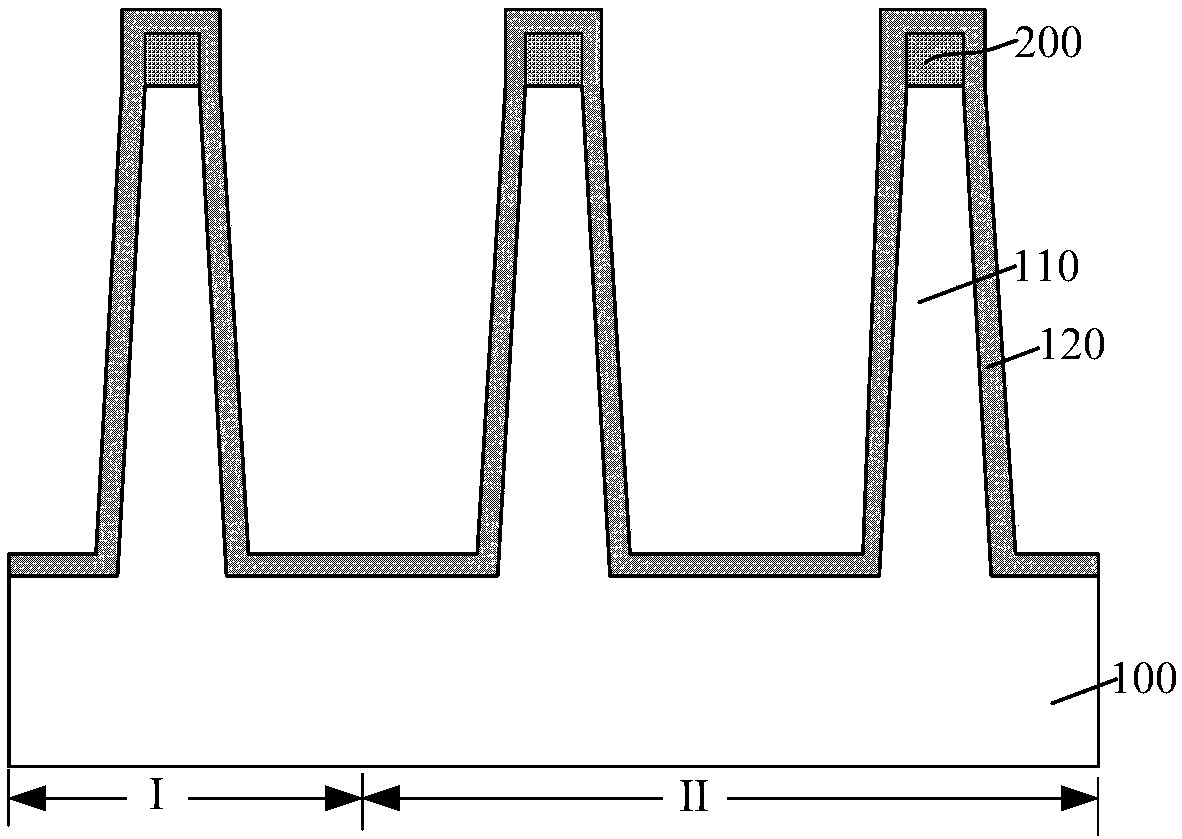

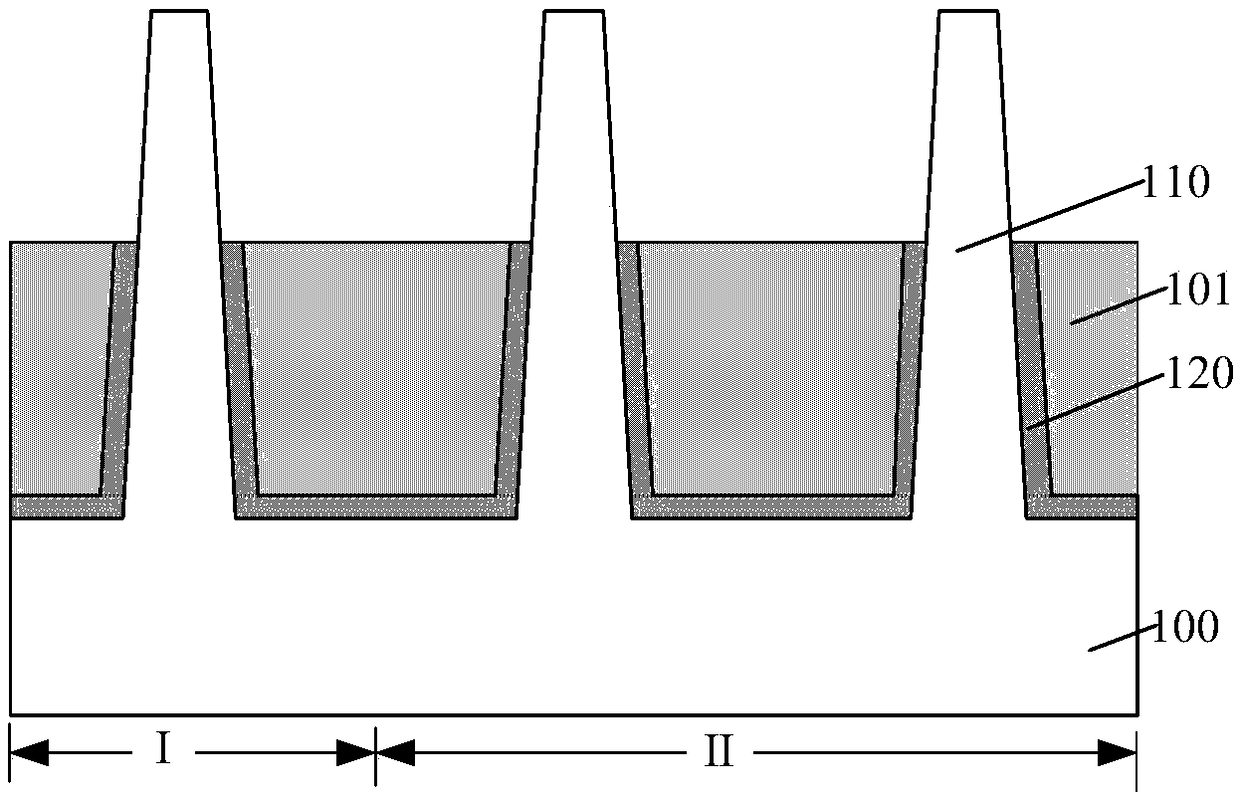

[0020] Therefore, a method for forming a semiconductor structure includes: providing a base, the base includes a substrate and discrete fins located on the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com