Breaker drive module

A technology for driving modules and circuit breakers, which is applied to contact drive mechanisms, protection switch operation/release mechanisms, etc., and can solve problems such as large influence, many detection positions, and incomplete gear meshing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

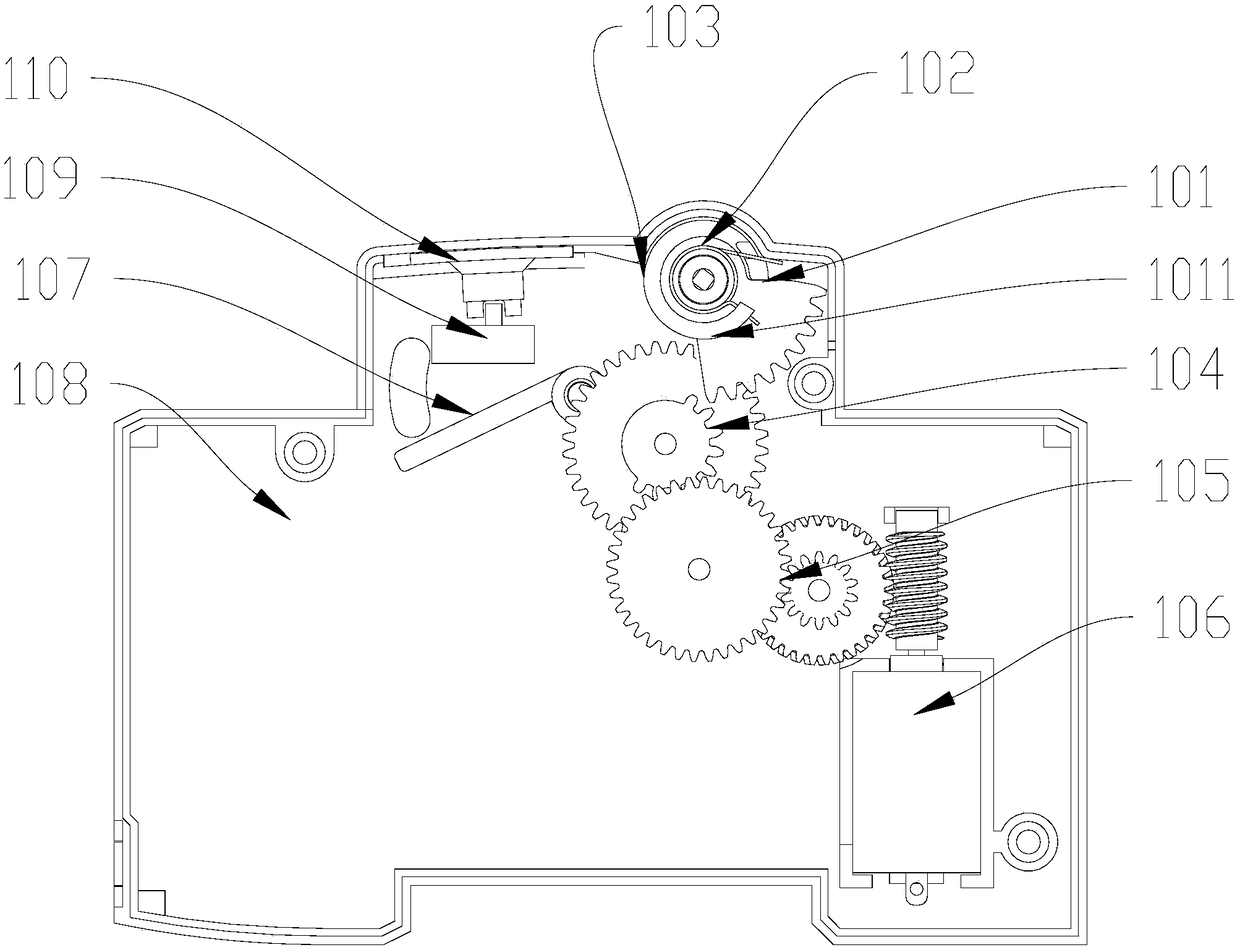

[0023] The following is attached Figures 1 to 7 The given examples further illustrate the specific implementation of the driving module of the circuit breaker created by the present invention. The driving module of the circuit breaker created by the present invention is not limited to the description of the following embodiments.

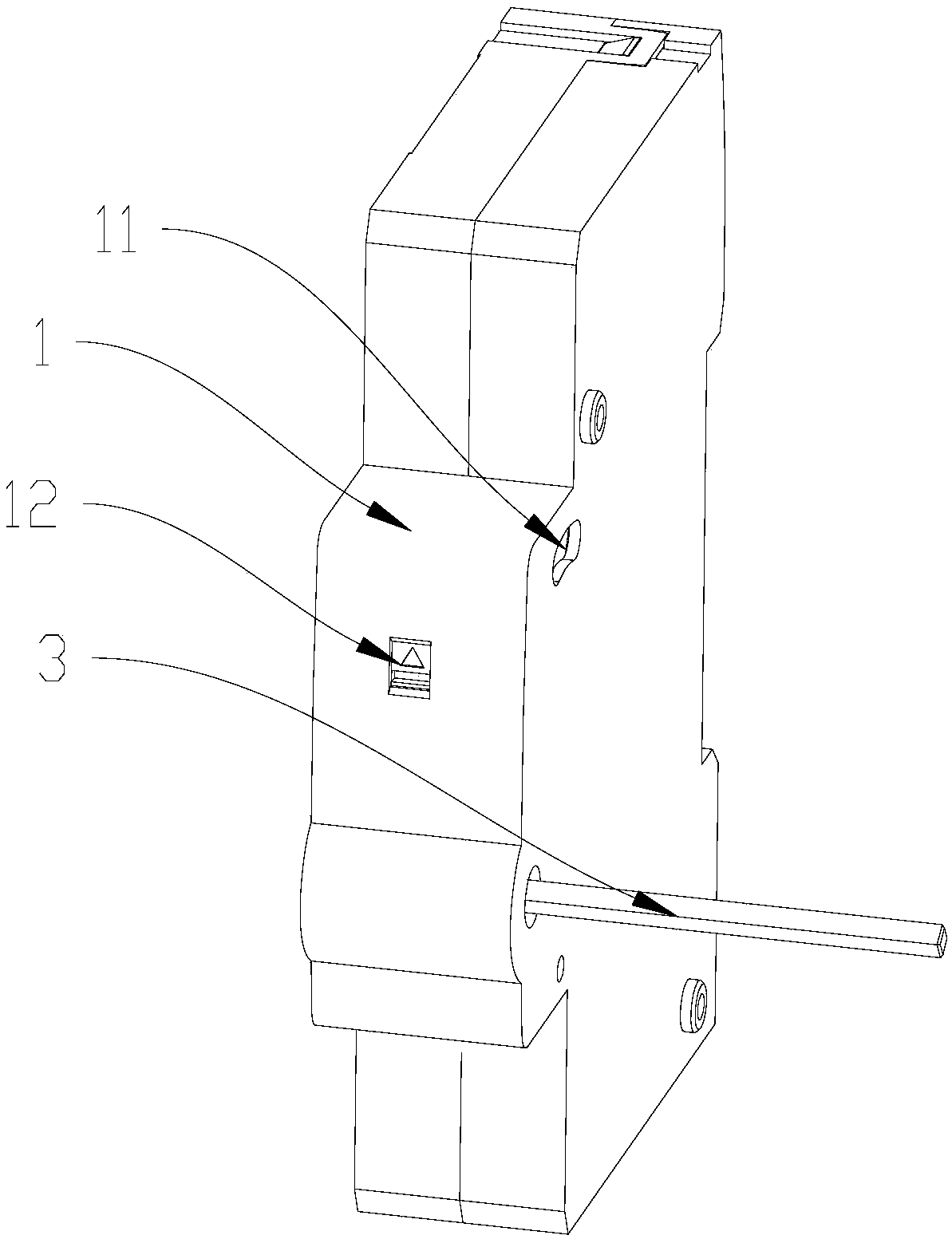

[0024] The drive module of the circuit breaker, used to connect with the circuit breaker, such as figure 1 In the embodiment of a drive module shown, the drive module 1 is arranged side by side with the circuit breaker, and is connected to the handle of the circuit breaker through the drive shaft 3, and the drive module 1 can drive the drive shaft 3 to rotate so as to drive the handle of the circuit breaker to close; A drive hole 11 corresponding to the operating mechanism of the circuit breaker is provided on the side wall of the drive module 1, and the drive module 1 can trigger the tripping of the circuit breaker through the drive rod extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com