Bearing stop pin shaft

A stop pin and stop technology, applied in the direction of pivot connection, etc., can solve the problems of structural weight and local stress corrosion of space thread parts, and achieve the effect of avoiding local structural corrosion and fatigue, reducing structural weight and saving structural space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

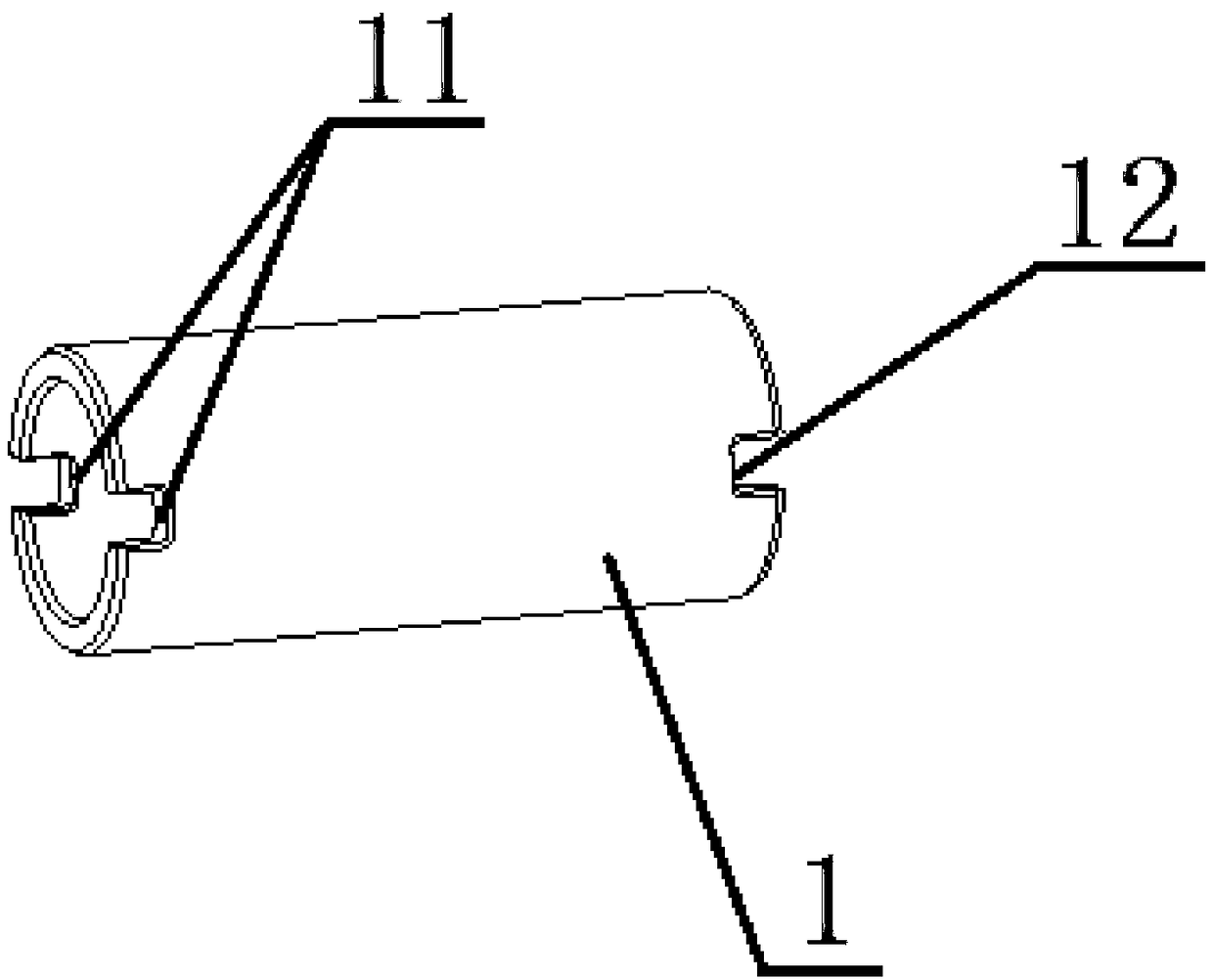

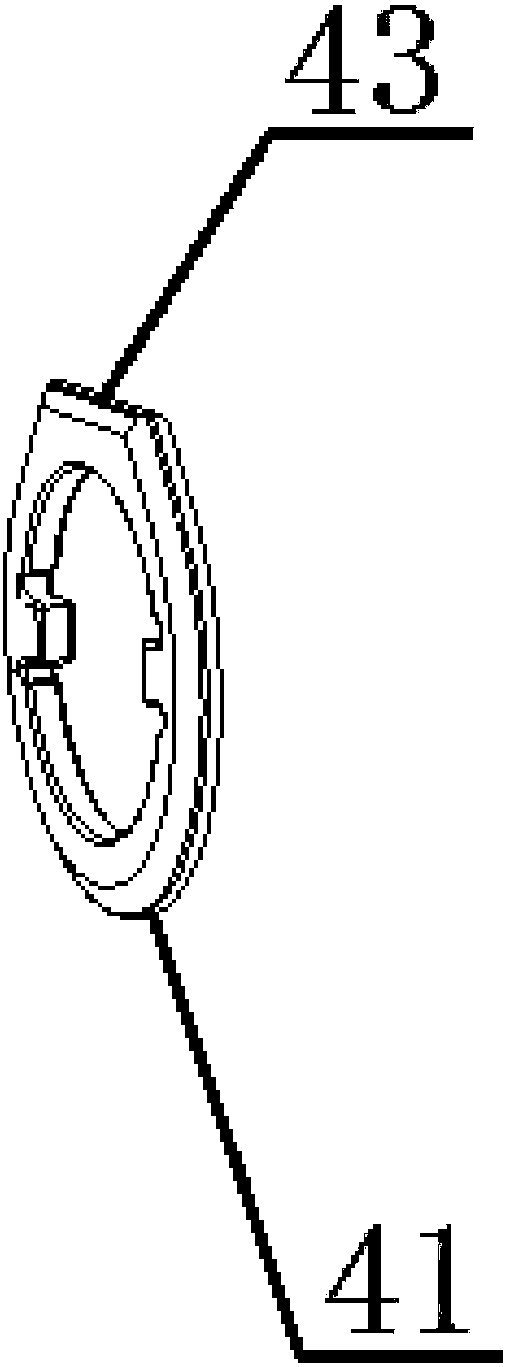

[0030] The bearing stop pin provided by the present invention is as figure 1 As shown, it is used for bearing and hinge between the first connecting piece 8 and the second connecting piece 9, the stopper pin includes a hollow pin 1, a stopper, a first retaining ring 2, a second retaining ring 3 and Transmission Parts.

[0031] The hollow pin shaft 1 runs through the first connecting piece 8 and the second connecting piece 9, the outer wall of the hollow pin shaft 1 is in contact with the first connecting piece 8 and the second connecting piece 9 respectively, and the first connecting piece is carried by the hollow pin shaft 1 Part 8 and the load of the second connecting part 9, such as figure 2 As shown, a groove A11 is formed on one end surface of the hollow pin shaft 1, and a groove B12 is formed on the other end surface of the hollow pin shaft 1. In this embodiment, the groove A11 is symmetrically arranged on both radial sides of the hollow pin shaft 1. , The groove B12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com