Reversing valve

A reversing valve and axial technology, which is applied in the field of reversing valves, can solve the problems that parts are vulnerable to impact damage, etc., and achieve the effects of convenient assembly process, alleviating liquid impact force, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

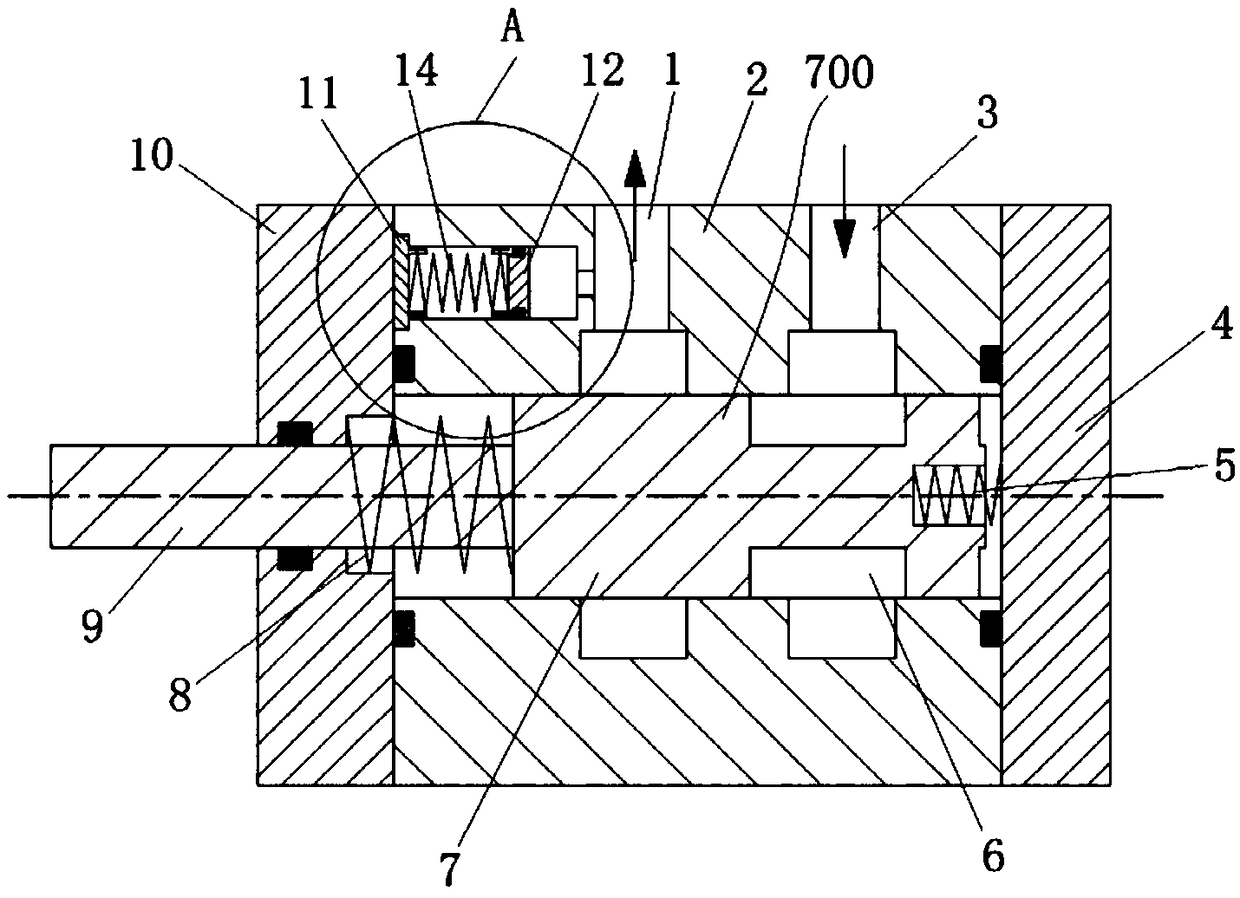

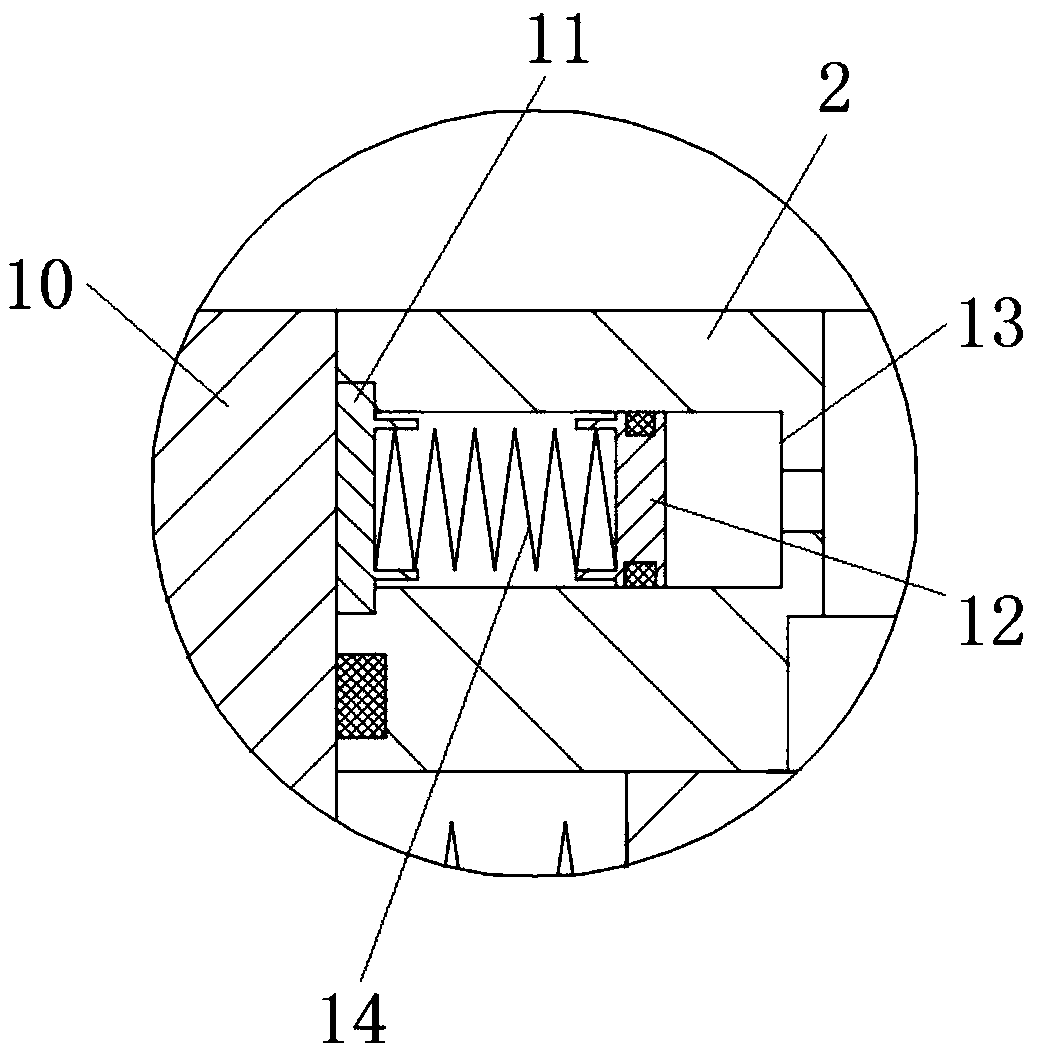

[0021] The specific embodiment of reversing valve of the present invention, as Figure 1 to Figure 2 As shown, the reversing valve in this embodiment is a two-position two-way solenoid valve.

[0022] The reversing valve includes a valve body 2, the center of the valve body 2 is provided with a through axial center hole, and the axial center hole is equipped with a valve core 700 moving along the left and right directions, and the left and right ends of the valve body 2 are respectively packaged with end caps. 10 and the bottom plate 4, the specific assembly method is bolt connection (of course, in other embodiments, other methods can be used for connection, such as press-fitting, etc.), in order to ensure the connection between the end cover 10 and the valve body 2, the bottom plate 4 and the valve body 2 are sealed and assembled to prevent oil from se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com