Method and system for particulate filter regeneration

A particle filter, turbocharger technology, applied in the direction of membrane filter, chemical instruments and methods, transportation and packaging, etc., can solve the problem of insufficient heating of GPF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

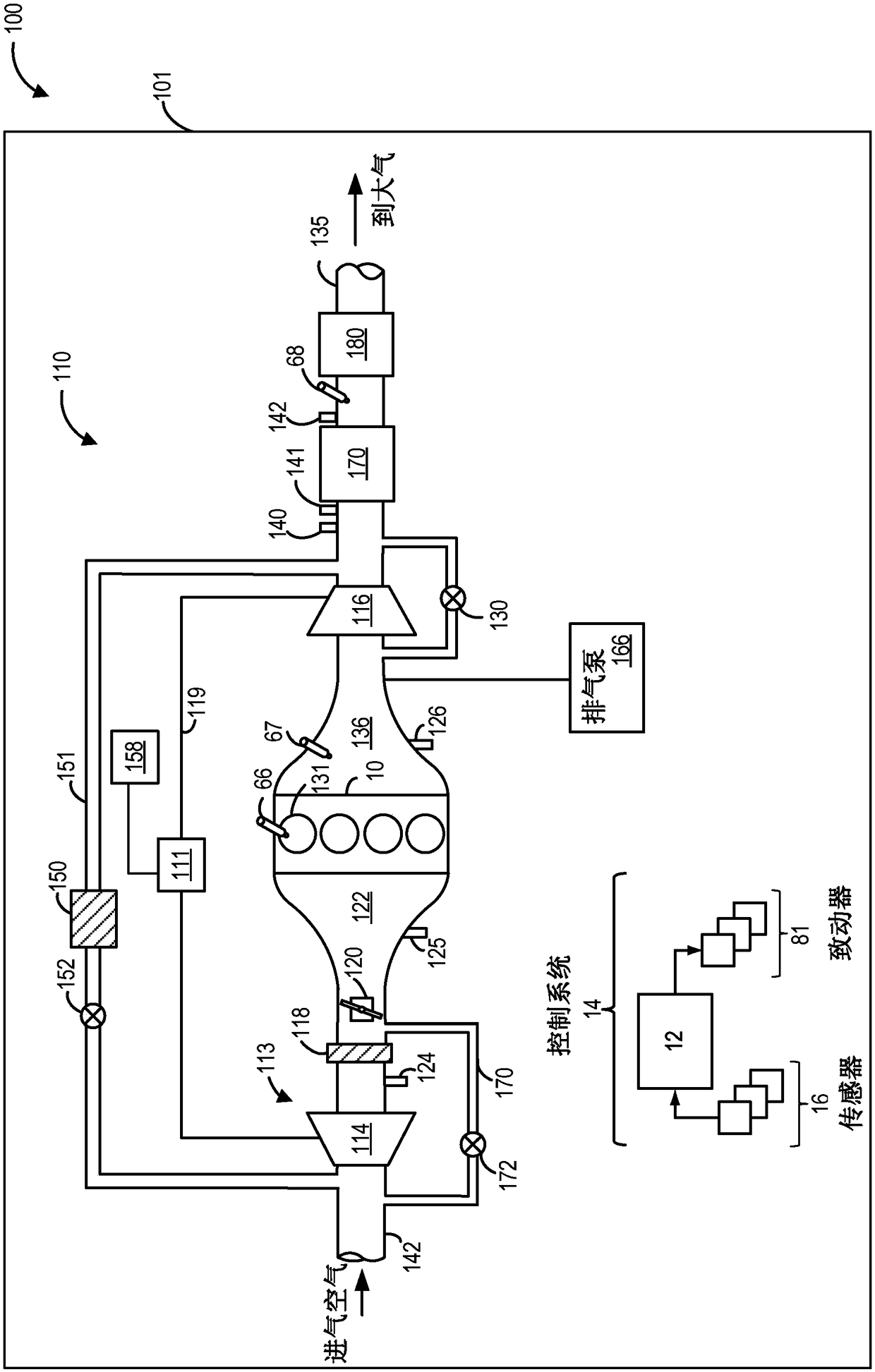

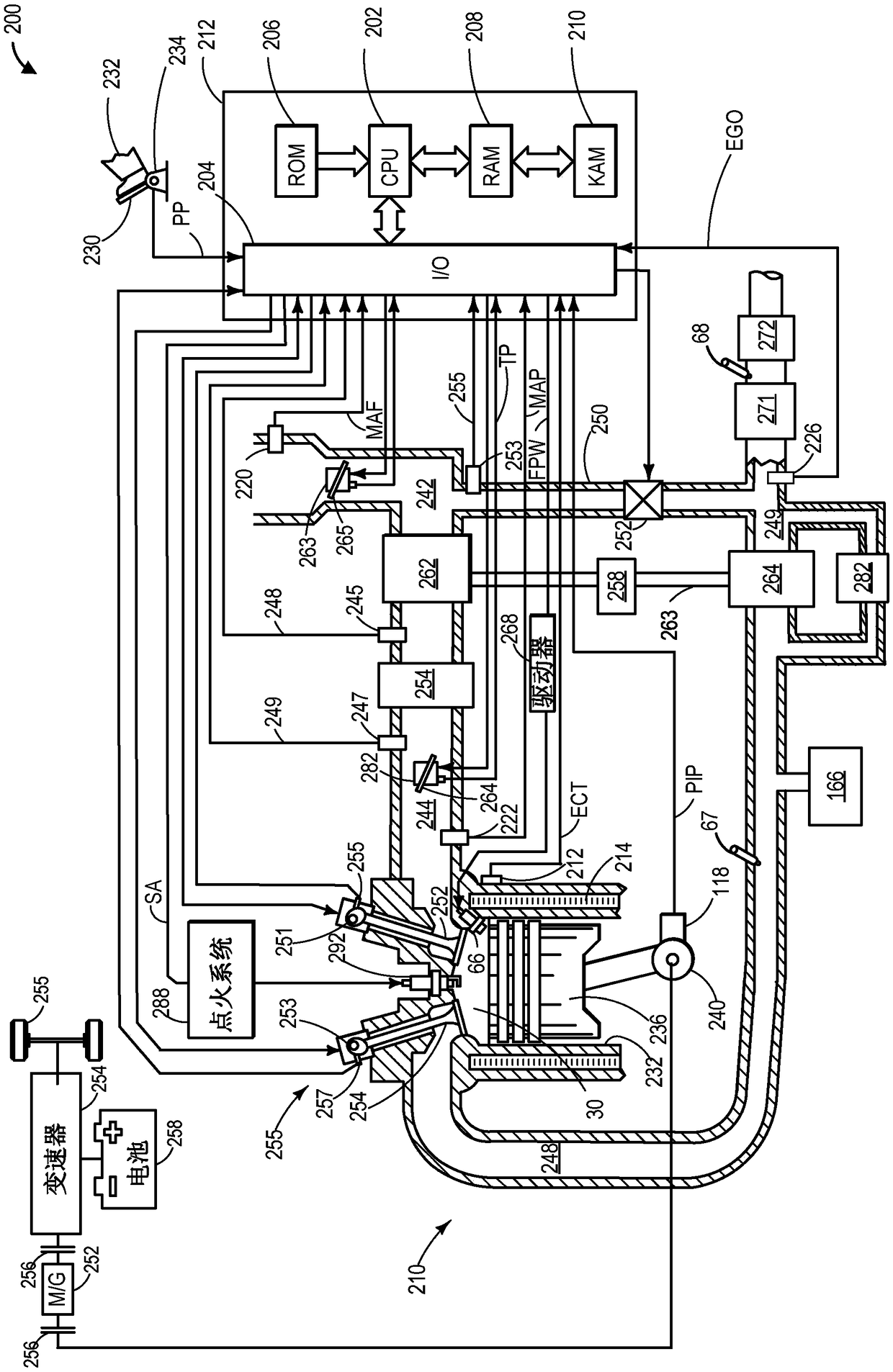

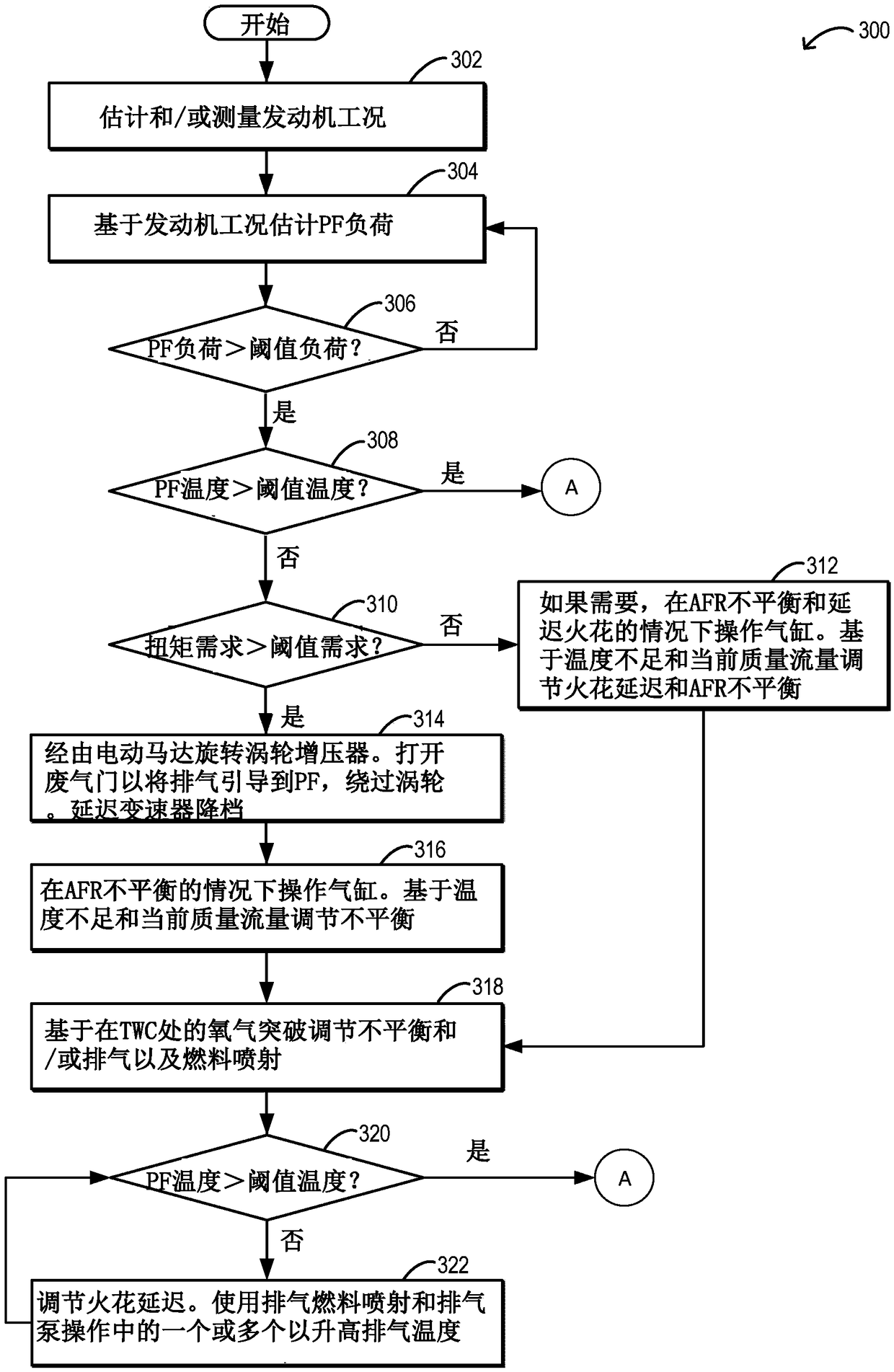

[0015] The following description relates to systems and methods for rapidly heating and frequently regenerating a gasoline particulate filter (GPF) coupled in a turbocharged engine system configured with electric assist, the turbocharged engine systems such as Figure 1-2 engine system. The engine system may further include an exhaust pump and an exhaust fuel injector so that the exhaust air-fuel ratio at the particulate filter can be adjusted differently from the combustion air-fuel ratio at the cylinder. The engine controller can be configured to execute control routines such as Figure 3-4 An example routine to expedite the heating of the particulate filter to an operating temperature where regeneration can be initiated. In particular, the controller may rely on the heat release generated via the cylinder air-fuel imbalance, which is enhanced using air flow regulation provided via the turbocharger. exist Figure 5 A prophetic example of coordinating electric turbocharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com