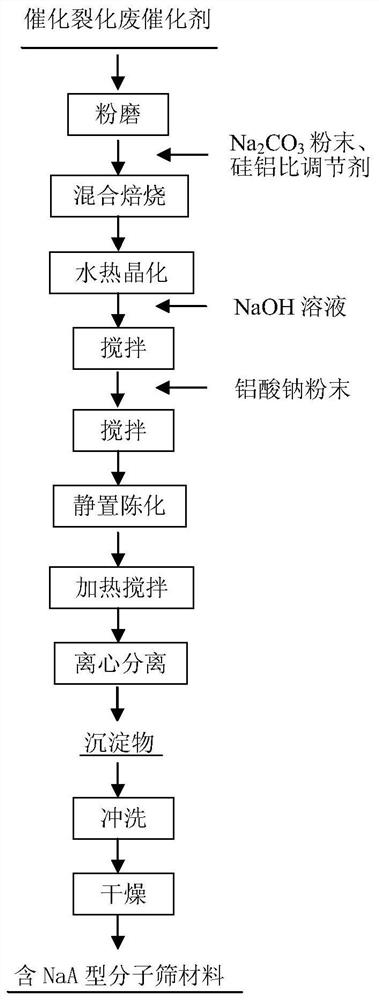

A method for synthesizing naa type molecular sieve material from catalytic cracking waste catalyst

A waste catalyst and catalytic cracking technology, which is applied in the field of resource utilization of solid waste, can solve the problems of unknown solidification effect of heavy metals such as nickel, various types of equipment, and complex composition of raw and auxiliary materials, so as to achieve resource utilization and simple material composition , the effect of easing the reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

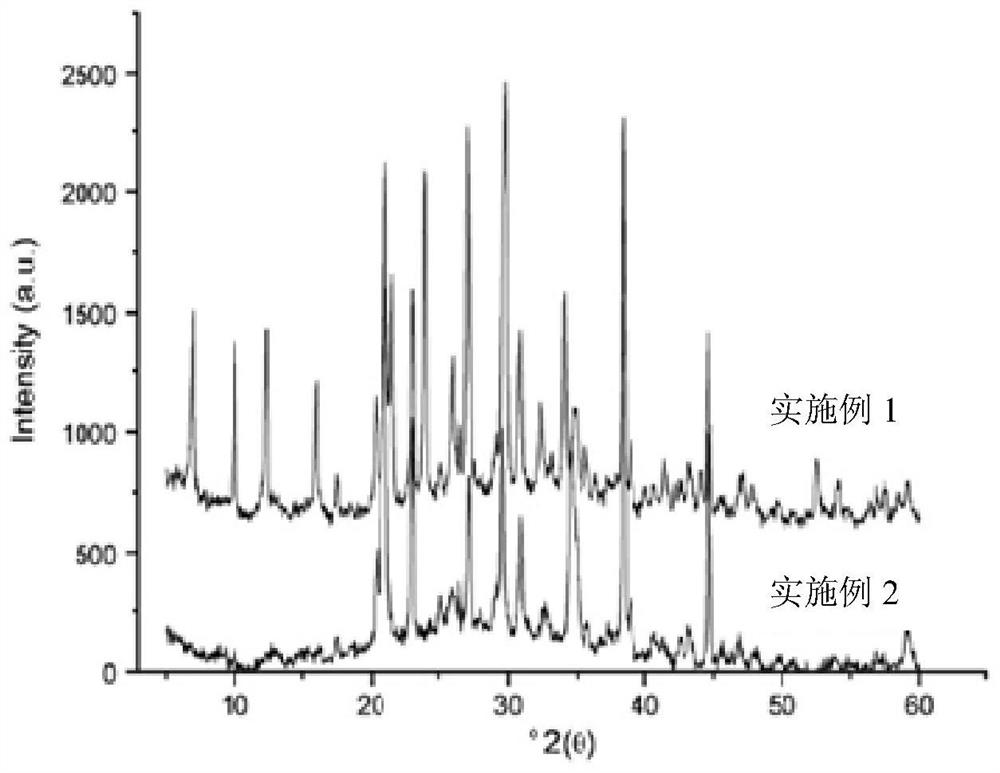

Embodiment 1

[0028] (1) The catalytic cracking waste catalyst is crushed, and the particle size of the catalytic cracking waste catalyst after crushing is 20-50 microns, 100 g of catalytic cracking scrap catalyst powder, 100g sodium carbonate and sodium silicate, high temperature roast 2 In the hour, the calcination temperature was 760 ° C, cooled to room temperature to obtain a solid melt;

[0029] (2) Put the splitter obtained by step (1) in a closed container, hot crystallization at a temperature of 95 ° C for 8 hours;

[0030] (3) The product obtained in step (2) is filtered, and the resulting filter material is added to 500 ml of 3.2 mol / L of sodium hydroxide solution, and stirred at room temperature for 1 hour; then add 77g aluminum Sodium sodium powder, after stirring for 1 hour, stand in an 18 hours;

[0031] (4) The aging mixture obtained by step (3) is heated to 80 ° C, and the temperature is stirred for 1.5 hours; the product is centrifuged, and the deionized water is flusted into...

Embodiment 2

[0034] (1) The catalytic cracking waste catalyst is crushed, and the particle size of the catalytic cracking waste catalyst after crushing is 20-50 microns, and 100 g of catalytic cracking scrap catalyst powder, 100 g sodium carbonate and 2g sodium silicate, high temperature roast 1 When the hour, the calcination temperature was 600 ° C, cooled to room temperature to obtain a solid melt;

[0035] (2) Place the splitter obtained by step (1) in a closed container, water crystallization at a temperature of 80 ° C for 3 hours;

[0036] (3) The product obtained in step (2) is filtered, and the resulting filter material is added to a sodium hydroxide solution of 500 ml of 3 mol / L, stirring at room temperature for 2 hours; then add 38.5 g of aluminum acid Sodium powder, continued to stir for 2 hours, static indulge in 24 hours;

[0037] (4) The aging mixture obtained by step (3) is heated to 60 ° C, and the temperature is stirred for 1 hour; the product is centrifuged, and the deionize...

Embodiment 3

[0039] (1) The catalytic cracking waste catalyst is crushed, and the particle diameter of the catalytic cracking waste catalyst after crushing is 20-50 microns, and 100 g of catalytic cracking scrap catalyst powder, 100 g sodium carbonate and 17.4 g of sodium silicate, high temperature calcination 3 hours, the calcination temperature was 900 ° C, cooled to room temperature to obtain a solid melt;

[0040] (2) Place the split body obtained by step (1) in a closed container, hot crystallization at a temperature of 110 ° C for 12 hours;

[0041] (3) The product obtained in step (2) is filtered, and the resulting filter material is added to 500 ml of 4 mol / L of sodium hydroxide solution, and stirred at room temperature for 2 hours; then 54.6 g of aluminum acid Sodium powder, continued to stir for 1 hour, stand for 12 hours;

[0042] (4) The aging mixture obtained by step (3) is heated to 90 ° C, and the temperature is stirred for 2 hours; the product is centrifuged, and the deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com