Double-side photovoltaic assembly

A photovoltaic module, double-sided technology, applied in the field of double-sided photovoltaic modules, can solve the problems of reducing the service life of components, hot spot effect, and reducing the service life of components, so as to reduce the impact of power generation, improve the power of the back side, and improve the use of The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present disclosure provides a double-sided photovoltaic module, including: at least one battery string group, a bypass diode connected in parallel with the corresponding battery string group, and a shield fixed on a backplane;

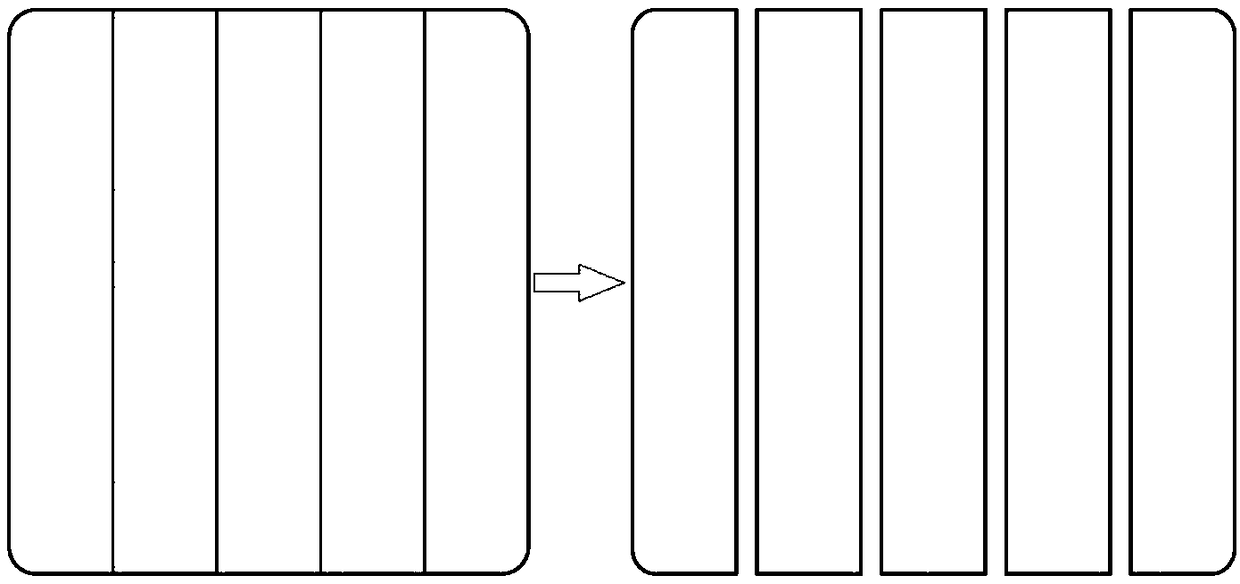

[0057] The battery string group is composed of battery strings connected in parallel, and the battery string is composed of battery pieces in series;

[0058] The battery slices that are at least partly shielded by the shielding object are shielded battery slices, and the battery string containing the shielded battery slices is the shielded battery string;

[0059] The number of shielded battery slices in each shielded battery string is greater than or equal to 2.

[0060] Preferably, the shaded area of each shaded cell is less than or equal to 50% of the total area of the back of the corresponding shaded cell. In this way, the shaded cells can still generate electricity, while avoiding all the shaded cells being blocked and becoming load power ...

Embodiment 2

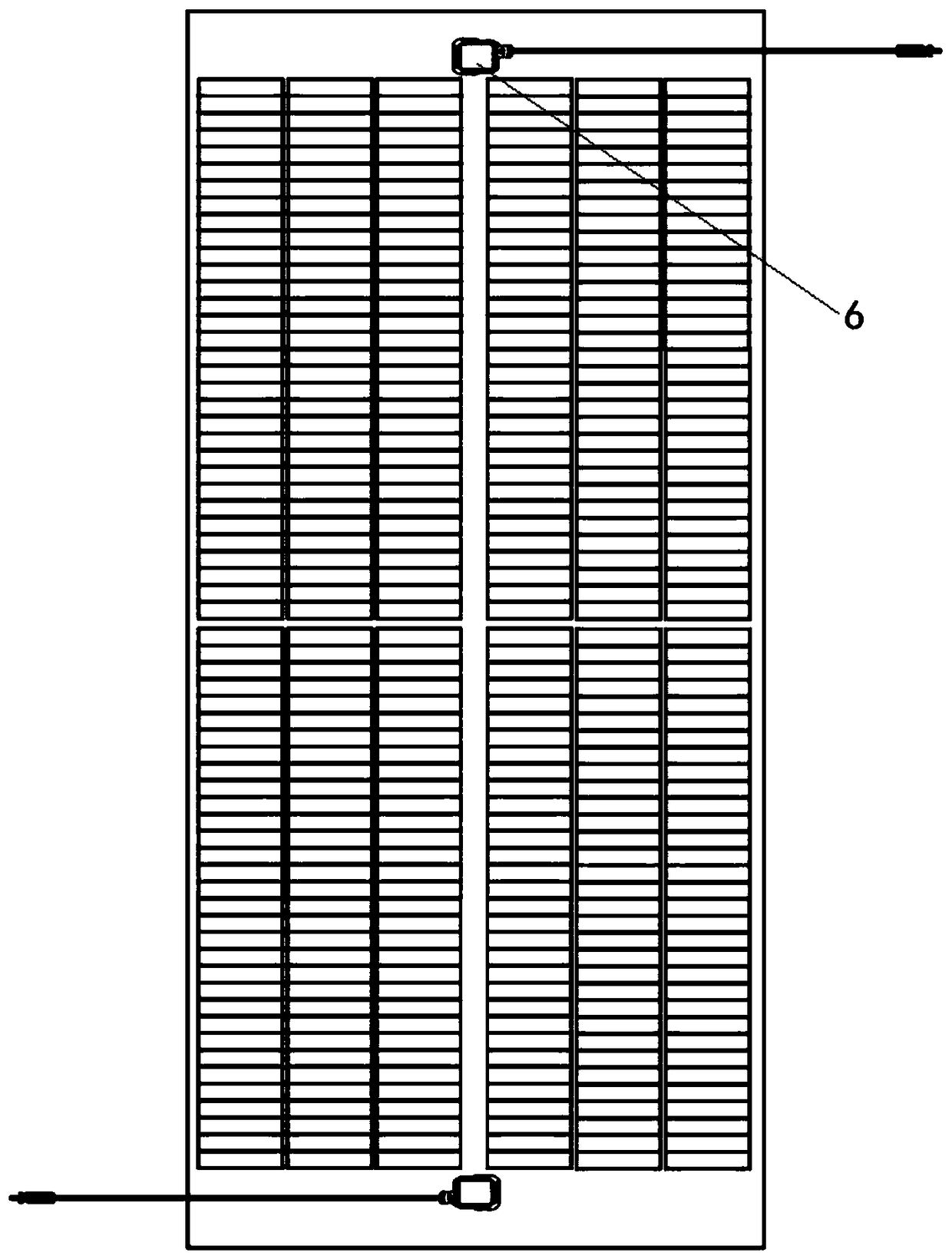

[0099] Based on the two-sided photovoltaic module described in the embodiment, a specific embodiment of the present disclosure is Picture 12 As shown, the double-sided photovoltaic module includes 6 battery strings, from left to right, A, B, C, D, E, F, each battery string is composed of 76 double-sided battery slices, each battery The length of the slice is 156.75mm, the width is 26.125mm, the shape of the battery slice is rectangle or rounded rectangle, and the rounded rectangle has rounded corners of 1, 2, 3 or 4. The overlapping distance of adjacent battery slices is 1 mm. The junction box 6 is installed at the dotted box,

[0100] The two ends of the long battery string ABCDEF are respectively connected to the bus bar 2 at both ends of the assembly through the welding ribbon 1; the bus bar 2 is connected to the bypass diode in the junction box 6 through the lead wire. The long battery string ABCDEF is composed of two short strings, and the short strings are connected by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com