Heat dissipation enhancement packaging structure for frame-type products, and manufacturing method

A technology of packaging structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of low production efficiency in the packaging process, increase the thickness of the package body, etc., and achieve effective heat dissipation and firm connection relationship Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

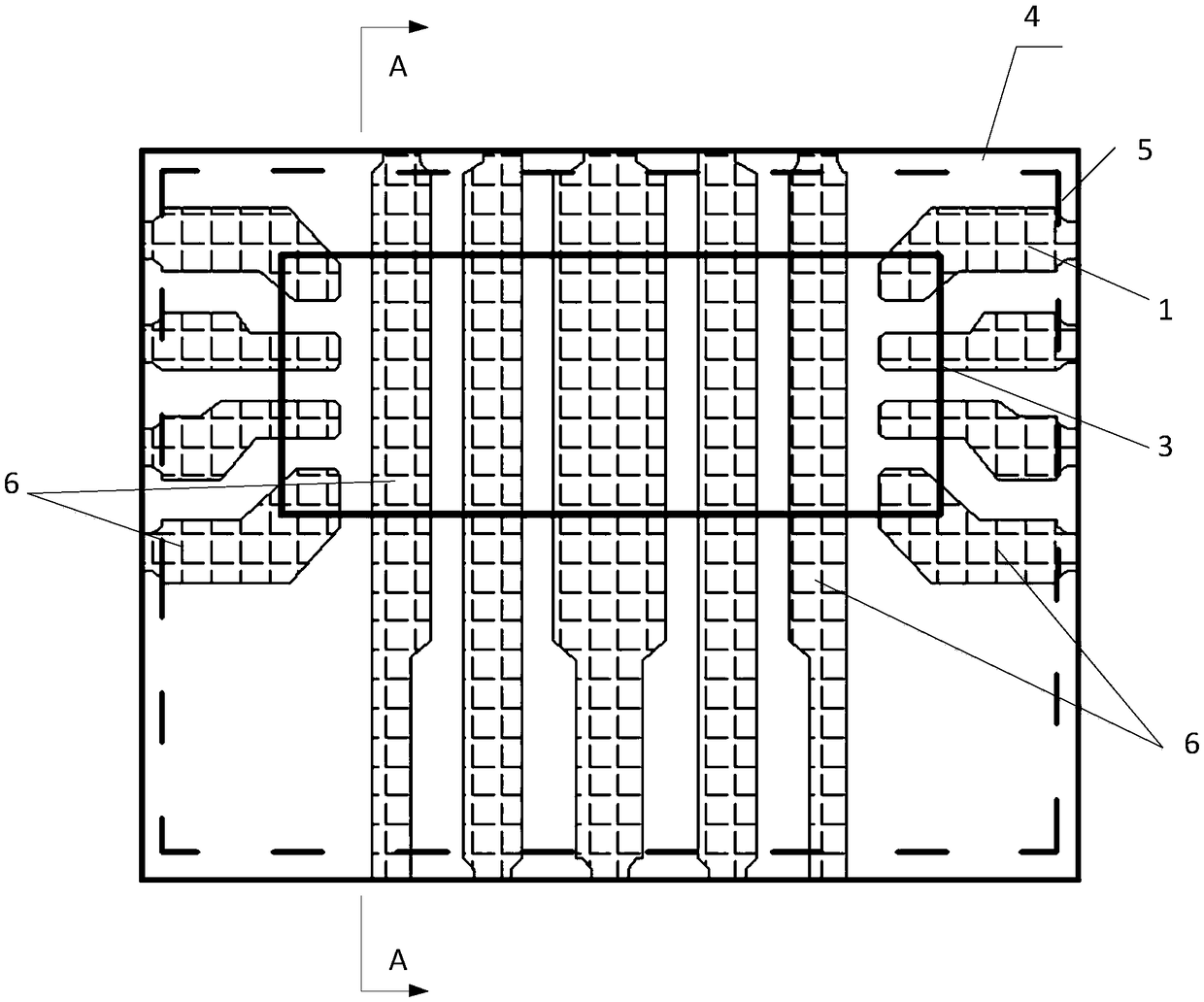

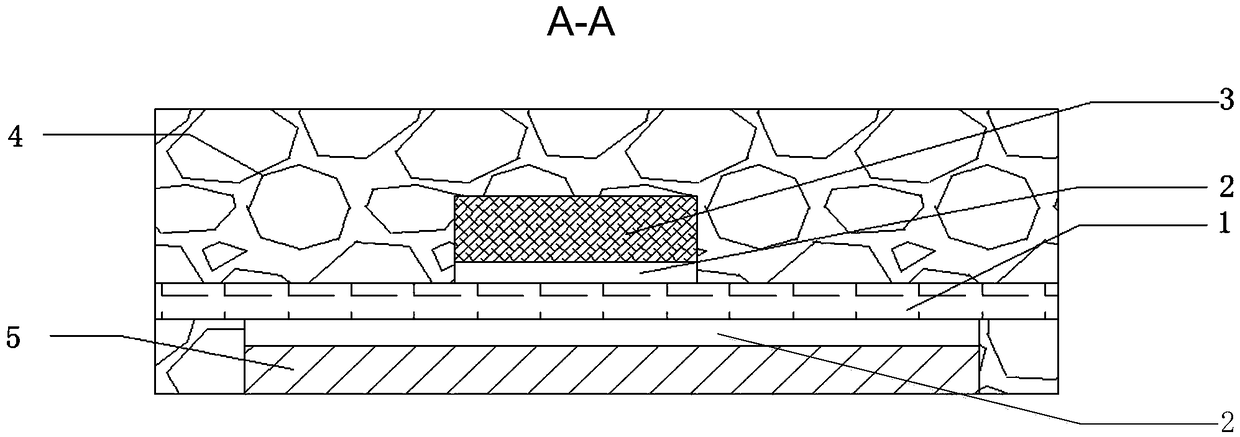

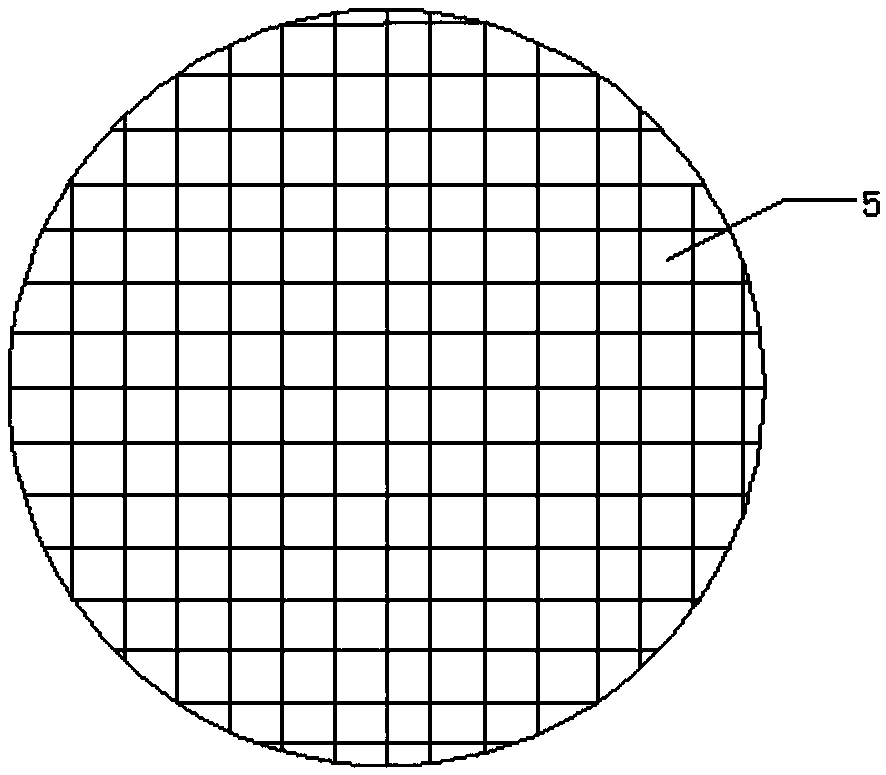

[0029] see figure 1 and figure 2 , the invention discloses a packaging structure and a manufacturing method for enhancing heat dissipation of frame products; The frame 1 is composed of several pins 6, and the arrangement of the pins 6 is not required, as long as no contact is required. The upper surface of the frame 1 is fixedly bonded with a chip 3 through the adhesive film 2, and the lower surface of the frame 1 is fixedly bonded with a heat sink 5 through the adhesive film 2; the chip 3 corresponds to the heat sink 5, that is, in the corresponding area of the heat sink 5, The chip 3 is fixedly connected on the upper surface of the frame 1 . The resin 4 wraps around the chip 3, the heat sink 5, and the frame 1; that is, the resin 4 fills each gap of the package structure, and the size of the chip 3 needs to ensure that the lower surface of the chip 3 is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com