Detecting device of vehicle wheel braking space

一种检测装置、空间的技术,应用在空间检测装置领域,能够解决效率低、检测效果差、不能适应自动化生产等问题,达到操作简单、性能稳定、结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

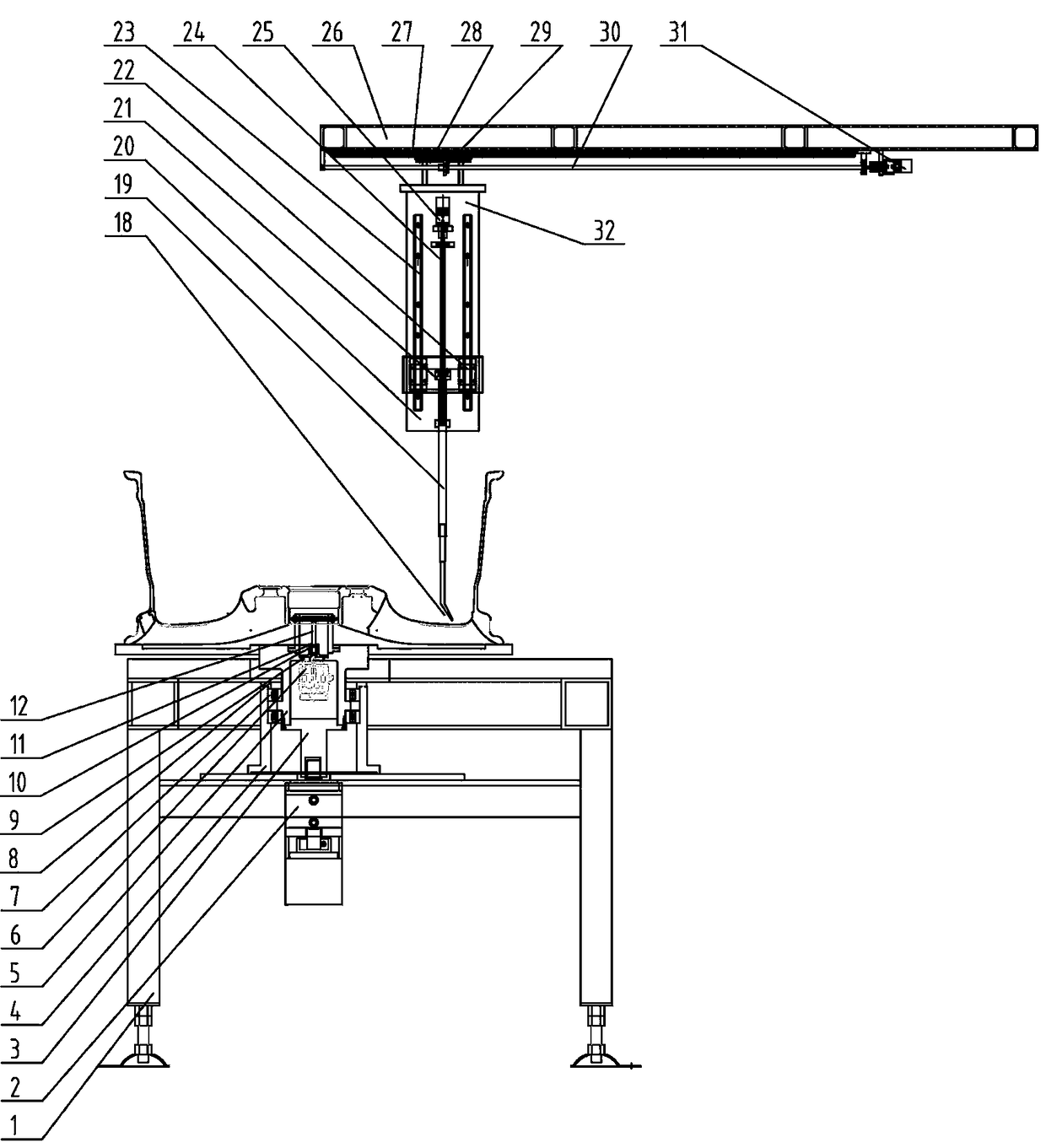

[0017] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

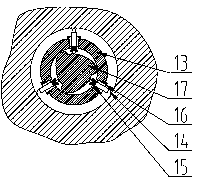

[0018] A wheel brake space detection device of the present invention consists of a frame 1, a servo motor A2, a connecting shaft 3, a base 4, a rotating shaft 5, a rotary oil cylinder 6, a bearing A7, a bearing end cover A8, a base 9, a bearing B10, and a bearing end Cover B11, shaft 12, shaft sleeve 13, contact 14, spring 15, linear bearing 16, synchronous cam 17, probe 18, probe bracket 19, sliding frame A20, screw nut A21, rail slide seat A22, linear guide rail A23, Ball screw A24, servo motor B25, suspension 26, linear guide rail B27, rail slider B28, screw nut B29, ball screw B30, servo motor C31, sliding frame B32.

[0019] The servo motor A2 and the base 4 are installed on the frame 1; the rotating shaft 5 is connected to the output shaft of the servo motor A2 through the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com