A kind of cyclic fermentation method of propionibacterium

A technology of propionibacterium and cyclic fermentation, which is applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of bacterial loss and other problems, and achieve the enhancement of bacterial metabolites, cost reduction, and product cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

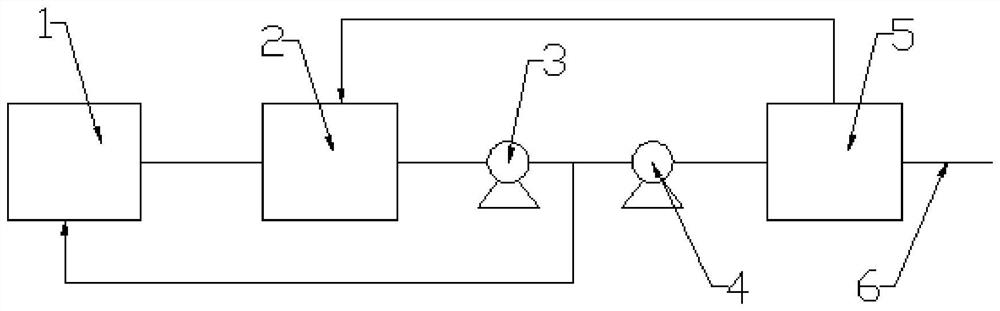

Image

Examples

Embodiment 1

[0029] A method for circulating fermentation of propionibacterium, comprising the following steps:

[0030] (1) The cultured propionibacterium thalline enters the fermenter containing the culture medium for fermentation to obtain a fermented liquid;

[0031] (2) The fermented liquid in step (1) is subjected to ceramic membrane circulation filtration to obtain the primary thalline concentrated solution, the volume of the primary thalline concentrated liquid is 25% of the total volume of the fermented liquid, and an equal volume is added to the primary thalline concentrated liquid The sterile pure water, and then continue to filter through the ceramic membrane to obtain the secondary cell concentrate, the volume of the secondary cell concentrate is the same as the volume of the primary cell concentrate, and the secondary cell concentrate is sent to the fermenter In the process, fresh culture medium is supplemented for fermentation, the volume ratio of the secondary bacterium con...

Embodiment 2

[0040] This embodiment is basically the same as Example 1, except that in step (2), the fermented liquid is circulated and filtered through a ceramic membrane to obtain a primary cell concentrate, and the volume of the primary cell concentrate is 24% of the total volume of the fermentation liquid , add an equal volume of sterile pure water to the primary cell concentrate, and then continue to perform ceramic membrane circulation filtration to obtain a secondary cell concentrate, the volume of the secondary cell concentrate is the same as that of the primary cell concentrate, Send the secondary bacterial cell concentrate to the fermenter, and add new medium, the volume ratio of the secondary bacterial cell concentrated liquid to the fresh medium is 1:2.5.

[0041] The medium of fermentation tank in the step (1): calcium carbonate 12g / L, yeast extract powder 10g / L, glucose 35g / L, pH value is natural; Along with carrying out in the fermentation tank, according to the variation of ...

Embodiment 3

[0044] This embodiment is basically the same as Example 1, except that in step (2), the fermented liquid is circulated and filtered through a ceramic membrane to obtain a primary cell concentrate, and the volume of the primary cell concentrate is 26% of the total volume of the fermented liquid , add an equal volume of sterile pure water to the primary cell concentrate, and then continue to perform ceramic membrane circulation filtration to obtain a secondary cell concentrate, the volume of the secondary cell concentrate is the same as that of the primary cell concentrate, The secondary bacterial cell concentrate is sent to the fermenter, and new medium is added, and the volume ratio of the secondary bacterial cell concentrated liquid to the fresh medium is 1:3.5.

[0045] The medium of fermentor in the step (1): calcium carbonate 15g / L, yeast extract powder 18g / L, glucose 40g / L, pH value is natural; Along with carrying out in fermentor, according to the change of fermented liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com