Test tube capable of moving liquid at upper end and test tube assembly

A test tube and pipetting technology, applied in the field of laboratory containers, can solve the problems of cross-contamination, inconvenient use, etc., and achieve the effect of convenient pipetting, avoiding contamination, and low proficiency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing.

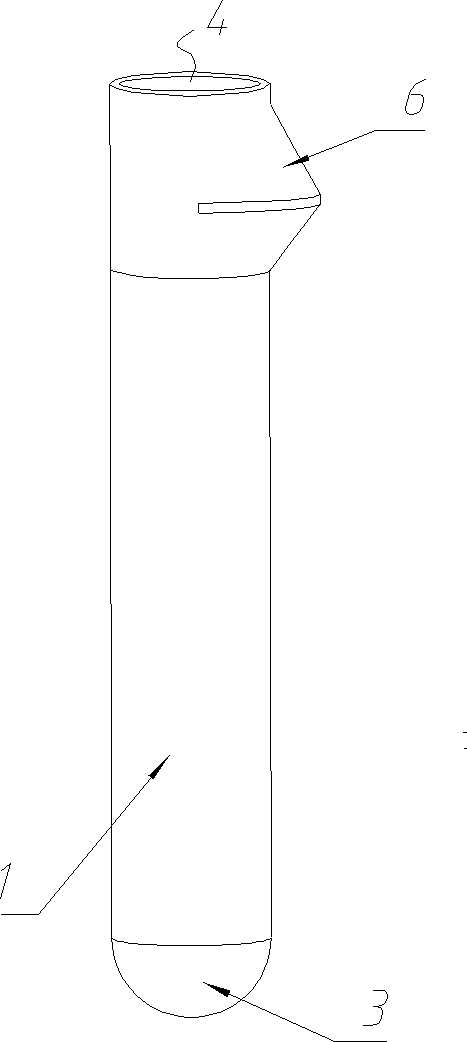

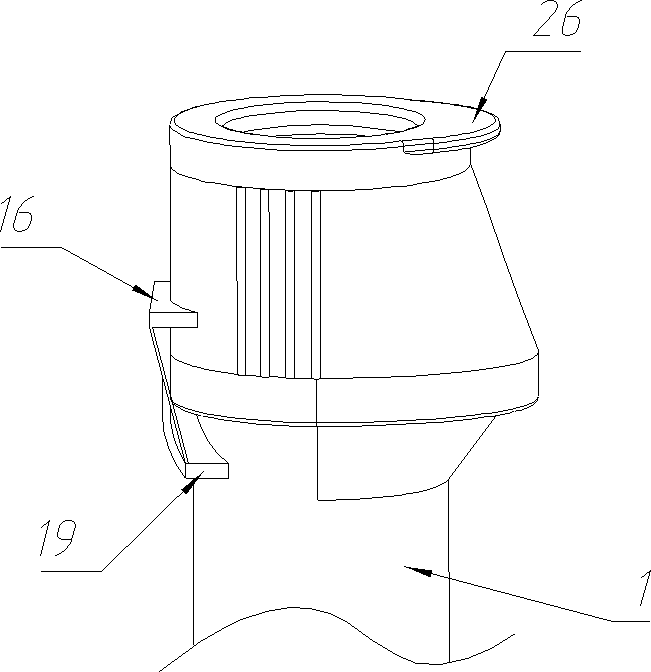

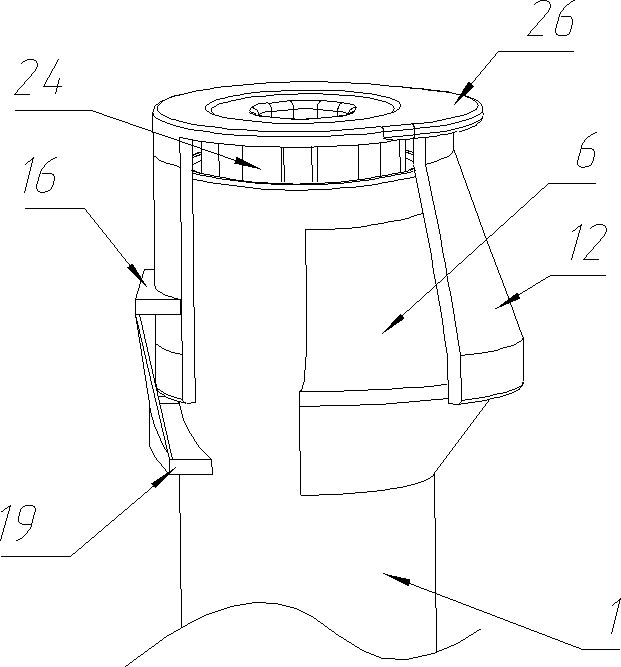

[0064] Embodiment 1 of the test tube that can be pipetted at the upper end in the present invention is as Figure 1-Figure 3 As shown, the lower part is a cylindrical tube body 1. The tube body 1 includes a tube side wall 2 and a round-bottomed tube bottom 3 closed at the lower end of the tube side wall 2. The upper end of the tube side wall 2 is provided with a nozzle 4. The upper part of the side wall 2 is provided with a wall bulge 6 that bulges toward the radial side of the pipe body 1 below the nozzle 4. The wall bulge 6 is a unidirectional wall bulge. The inner cavity surrounded by the side wall 2 forms a concave cavity 5 for the liquid inside the tube body 1 to flow into, and the concave cavity 5 is a single-sided concave cavity. In the axial direction of the tube body 1, the radial size of the wall bulge 6 gradually decreases from the middle to the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com