Oriented pyrolysis reactor based on ray heating

A technology of pyrolysis reactor and reactor, which is applied in the preparation of liquid hydrocarbon mixture, special carbonization, coking oven, etc., can solve the problems of uneven heat exchange, complex reactor structure, and easy blockage of pipelines, etc. Low ash content, fast and efficient pyrolysis, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

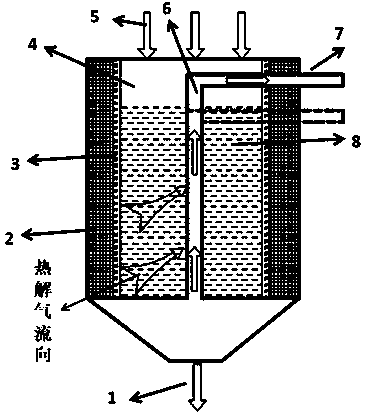

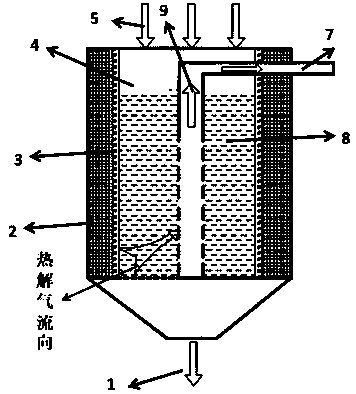

[0039] This embodiment is the intermittent pyrolysis of 5mm waste tire particles, such as figure 1As shown, the directional pyrolysis reactor includes a semi-coke discharge port 1, a thermal insulation and reflection layer 2, a ray emitting source 3, a ray heating chamber 4, a pyrolysis sample feed port 5 and a pyrolysis gas discharge port 7, wherein the The above-mentioned ray heating chamber 4 is also provided with a pyrolysis product channel 6, the wall of the pyrolysis product channel 6 is a plate structure with holes, and the ray emitting source 3 is an infrared emitter. 5mm waste tire particles are evenly filled around the pyrolysis product channel 6, and the upper part of the ray heating chamber 4 is sealed. Turn on the ray emitting source 3, the infrared ray quickly heats the external waste tire particles, and the pyrolysis reaction starts. The pyrolysis gas phase product enters the pyrolysis product channel 6 through the material bed 8, and finally collects into the ...

Embodiment 2

[0041] The present embodiment is the continuous pyrolysis of 5mm Fushun oil shale particles, such as figure 1 As shown, the directional pyrolysis reactor includes a semi-coke discharge port 1, a thermal insulation and reflection layer 2, a ray emitting source 3, a ray heating chamber 4, a pyrolysis sample feed port 5 and a pyrolysis gas discharge port 7, wherein the The above-mentioned ray heating chamber 4 is also provided with a pyrolysis product channel 6, the walls of the pyrolysis product channel 6 are parallel and spaced louver structures, and the ray emitting source 3 is a microwave emitter. The 5mm Fushun oil shale particles are continuously transported into the ray heating chamber 4 and evenly filled around the pyrolysis product channel 6 . Microwaves rapidly heat the oil shale particles, and the pyrolysis reaction begins. The pyrolysis gas phase product enters the pyrolysis product channel 6 through the material bed 8, and finally collects into the pyrolysis gas dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com