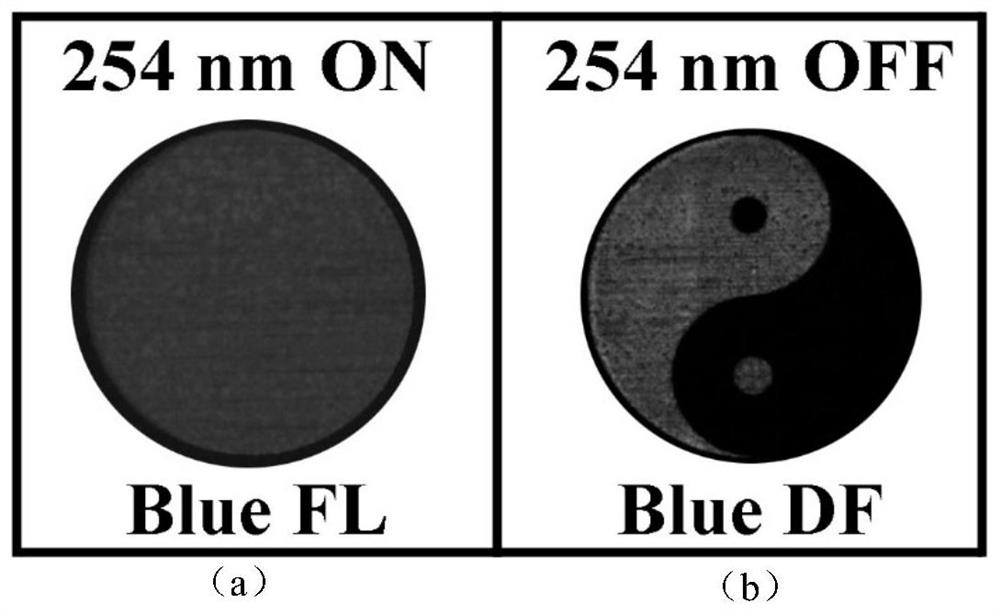

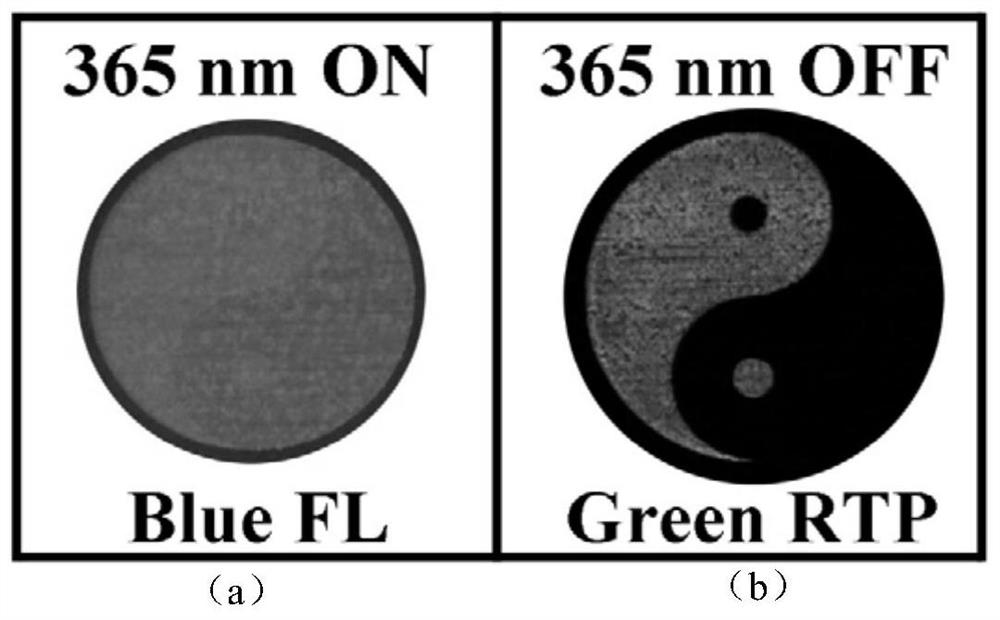

Triple optical anti-counterfeiting ink with fluorescence, delayed fluorescence and room temperature phosphorescence and anti-counterfeiting method and application

A technology of delayed fluorescence and room temperature phosphorescence, applied in inks, applications, household appliances, etc., can solve the problems of limited applications, achieve high encryption level, difficult forgery, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of carbon dot 1 (NCD1) and carbon dot 1 anti-counterfeiting ink with only fluorescence

[0028] Weigh 1g of folic acid and evenly disperse it in 30mL of toluene, transfer it to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, tighten the lid, and conduct a hydrothermal reaction at 290°C for 1h. Allow the reactor to cool down to room temperature naturally, and centrifuge for 5-10 minutes at a rotational speed of 8000 r / min to remove the supernatant. The precipitate was put into a vacuum drying oven, and dried under vacuum at 100° C. for 12 hours to obtain a solid powder of carbon dot 1 . Take 50 mg of carbon dot 1 solid powder and disperse it in 5 mL of deionized water to prepare 10 mg / mL carbon dot 1 anti-counterfeiting ink with only fluorescence.

[0029] Preparation of carbon dot 1 composite powder (NCD1-C)

[0030] Take 15mg of carbon dot 1 solid powder and disperse in 6mL of 1g / mL urea aqueous solution. The mixed solution was tra...

Embodiment 2

[0035] Preparation of carbon dots 2 (NCD2)

[0036] Weigh 1g of folic acid and evenly disperse it in 30mL of N,N-dimethylformamide, transfer it to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, tighten the lid of the kettle, and conduct a hydrothermal reaction at 290°C for 1h. Allow the reactor to cool down to room temperature naturally, and centrifuge for 5-10 minutes at a rotational speed of 8000 r / min to remove the supernatant. The precipitate was put into a vacuum drying oven, and dried under vacuum at 100° C. for 12 hours to obtain a solid powder of carbon dot 2 .

[0037] Preparation of carbon dots 2 composite powder (NCD2-C)

[0038] Take 15mg of carbon dot 2 solid powder and disperse in 6mL of 1g / mL urea aqueous solution. The mixed solution was transferred to a three-necked flask, and reacted in an oil bath at 180° C. until solids were precipitated. After natural cooling to room temperature, the carbon dots 2 composite powder containing nitro...

Embodiment 3

[0042] Preparation of carbon dots 3 (NCD3)

[0043] Weigh 1g of folic acid and evenly disperse it in 30mL of acetone, transfer it to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, tighten the lid of the kettle, and conduct a hydrothermal reaction at 290°C for 1h. Allow the reactor to cool down to room temperature naturally, and centrifuge for 5-10 minutes at a rotational speed of 8000 r / min to remove the supernatant. The precipitate was put into a vacuum drying oven, and dried under vacuum at 100° C. for 12 hours to obtain a solid powder of carbon dot 3 .

[0044] Preparation of carbon dot 3 composite powder (NCD3-C)

[0045] Take 15mg of carbon dot 3 solid powder and disperse in 6mL of 1g / mL urea aqueous solution. The mixed solution was transferred to a three-necked flask, and reacted in an oil bath at 180° C. until solids were precipitated. After natural cooling to room temperature, the carbon dots 3 composite powder containing nitrogen-doped carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com