Sewage treatment apparatus for environmental engineering

A technology of sewage treatment equipment and environmental engineering, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, infiltration/dialysis water/sewage treatment, etc. The effect of large flow, high oil removal efficiency and high filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

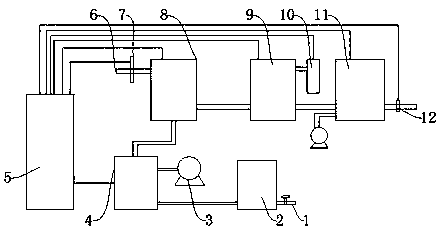

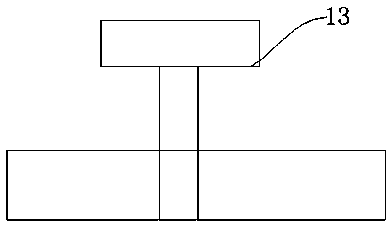

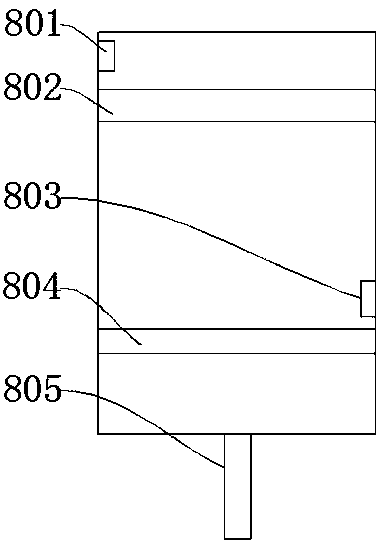

[0025] like Figure 1-Figure 4 As shown, a sewage treatment device for environmental engineering, comprising the sludge outlet 1, the heavy metal recovery box 2, the centrifugal mud pump 3, the sludge storage box 4, the sewage inlet 6, The electromagnetic control valve 7, the primary treatment tank 8, the heavy metal recovery tank 2 is arranged above the sludge outlet 1, the centrifugal dredge pump 3 is arranged above the heavy metal recovery tank 2, and the centrifugal pump 3 is arranged above the heavy metal recovery tank 2. The sludge storage box 4 is arranged above the sludge pump 3, the operation control box 5 is installed above the sludge storage box 4, and the sewage inlet 6 is installed above the operation control box 5. The electromagnetic control valve 7 is installed above the sewage inlet 6, the primary treatment box 8 is installed above the electromagnetic control valve 7, the secondary treatment box 9 is installed below the primary treatment box 8, and the seconda...

Embodiment 2

[0037] The general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, this embodiment does not have the pneumatic butterfly valve 1106, and the flow rate of purified water can be directly controlled by the electromagnetic control valve 7 , this method is simple in structure and saves cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com