Nursery stock planting conveyor

A conveyor and seedling technology, applied in conveyors, planting methods, transplanting machinery, etc., can solve problems such as damage to seedlings, unfavorable root growth and water balance of seedlings, and inability to provide convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

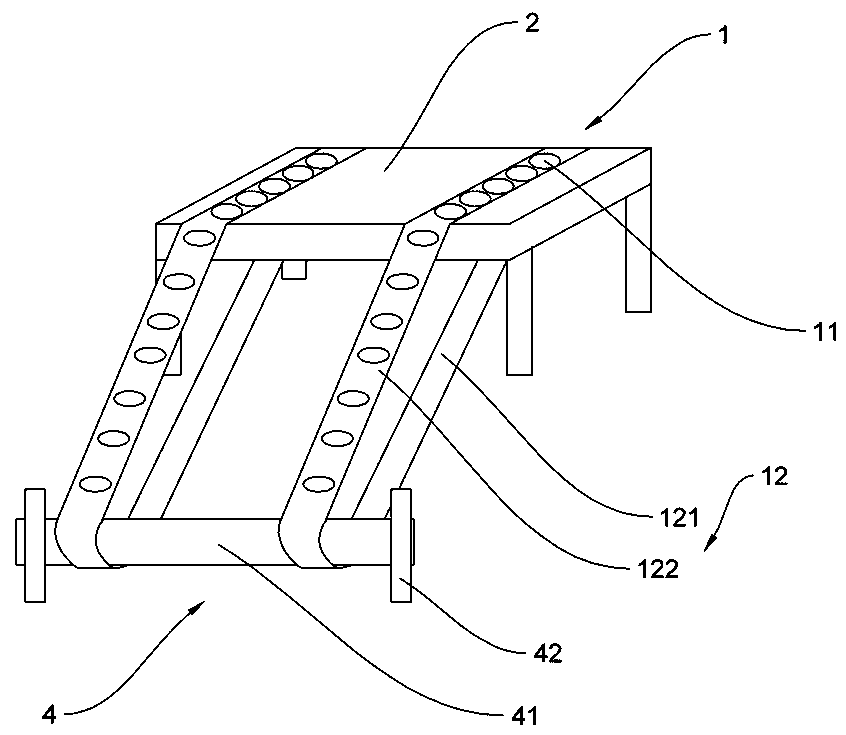

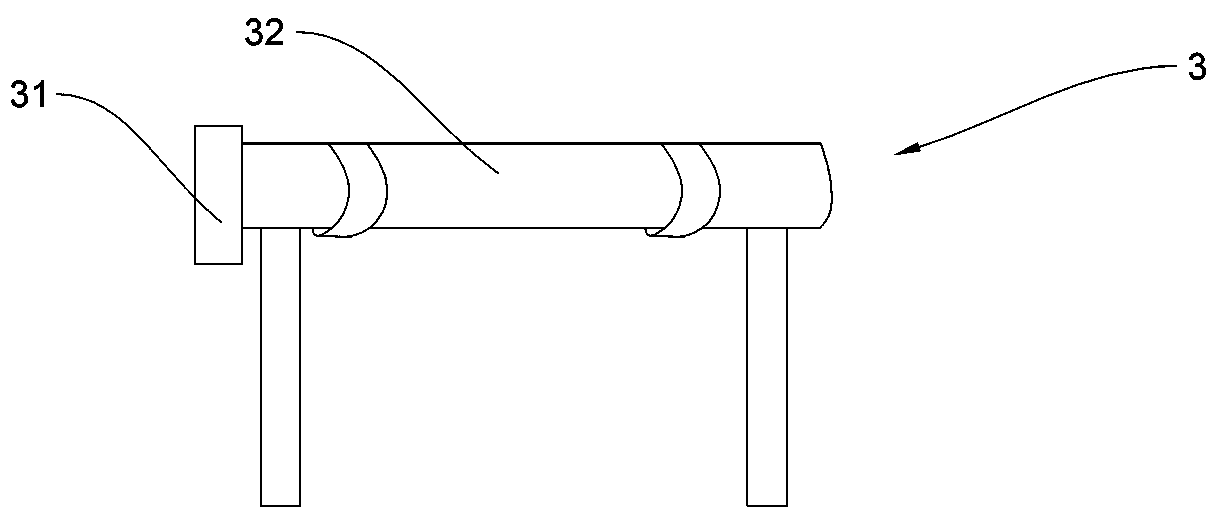

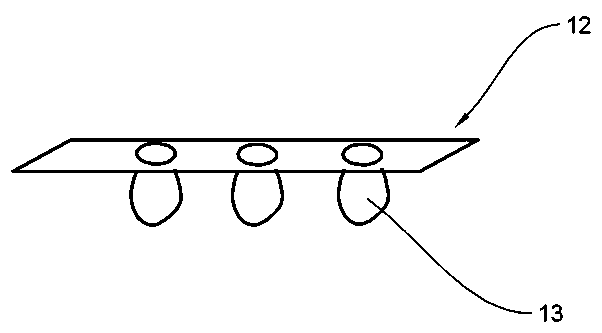

[0022] see figure 1 , figure 2 , image 3 , is a seedling planting conveyer, comprising a seedling conveying device 1, a seedling placement platform 2, the seedling conveying device 1 is placed on the seedling placing platform 2, and the seedling conveying device 1 includes a seedling The placement hole 11, the conveyor belt 12 that can rotate circularly so that the seedlings placed in the seedling placement hole 11 are delivered to the target position, the conveyor belt 12 includes an elastic part 121 whose length can be extended / compressed, and the elastic part 121 connected to the fixed portion 122, the seedling placement hole 11 is arranged on the fixed portion 122, the seedling placement hole 11 is affixed to the end of the fixing member 13 for holding the seedling, and also includes Pulling device 4 for stretching said conveyor belt 12 .

[0023] The conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com