Pipe fitting inner wall cleaning device

A technology for inner wall cleaning and pipe fittings, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of large labor consumption and low cutting efficiency, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

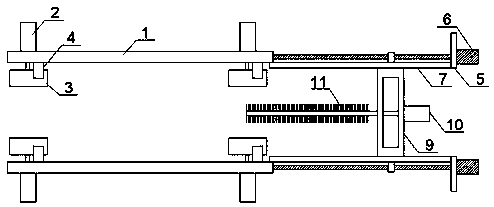

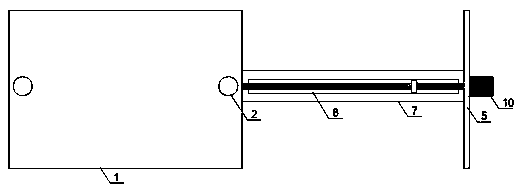

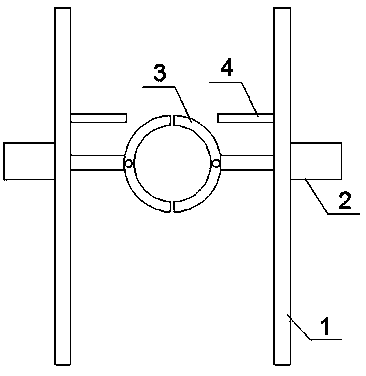

[0018] Such as Figure 1-4 As shown, the present invention discloses a cleaning device for the inner wall of pipe fittings, which includes a frame. The left and right ends of the front and rear planes of the frame 1 are respectively fixedly connected with a hydraulic cylinder 2, and the piston rod of the hydraulic cylinder 2 is connected to the center of the splint 3. Point rotation connection, four baffles 4 are fixedly connected to the inner wall of the frame 1 .

[0019] Preferably: it also includes a limiting plate 7 and a ball screw module 6, one end of the two limiting plates 7 is fixedly connected to the support plate 5, and the other end is fixedly connected to the frame 1; One end of the module 6 is connected with the support plate 5, and the other end is connected with the frame 1; the limit plate 7 is provided with a slide hole 8, and a slide plate 9 is slidably connected in the slide hole 8, and the front and back of the slide plate 9 The two ends are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com