Test tube shaking device

A test tube and driving seat technology, applied in the field of experimental equipment, can solve the problems of poor mixing effect, low efficiency, small shaking amplitude, etc., and achieve the effect of increasing the shaking amplitude, improving the shaking effect, and increasing the centrifugal force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

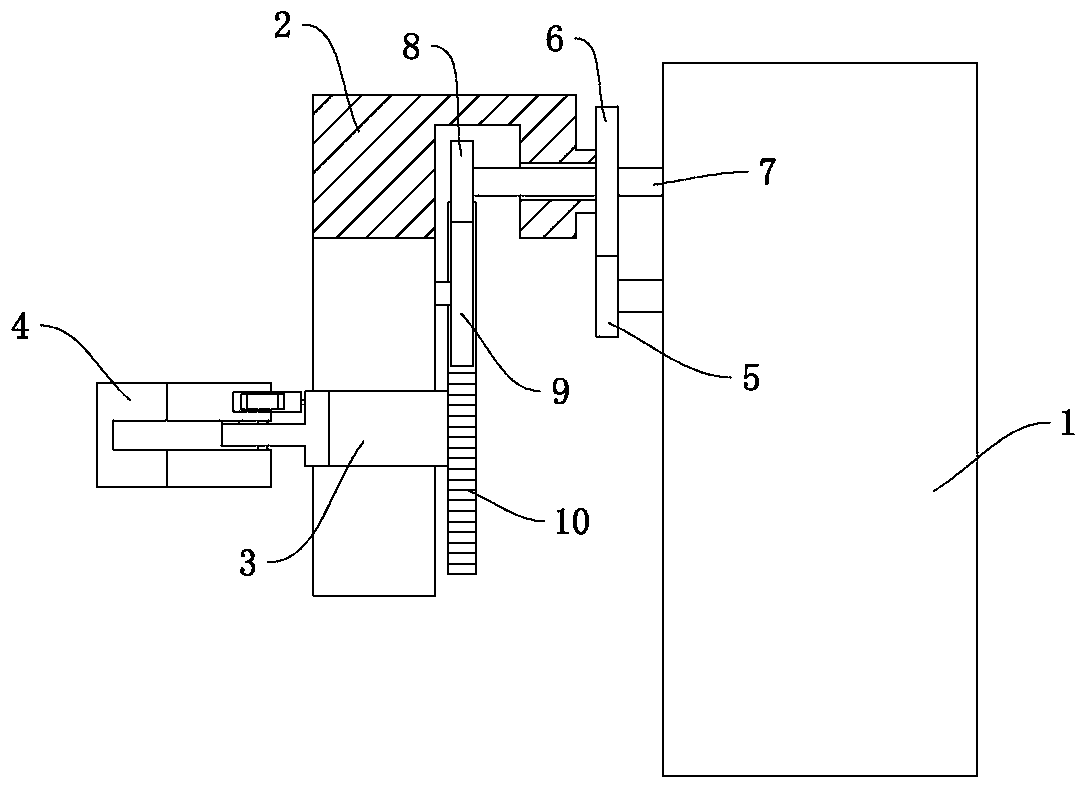

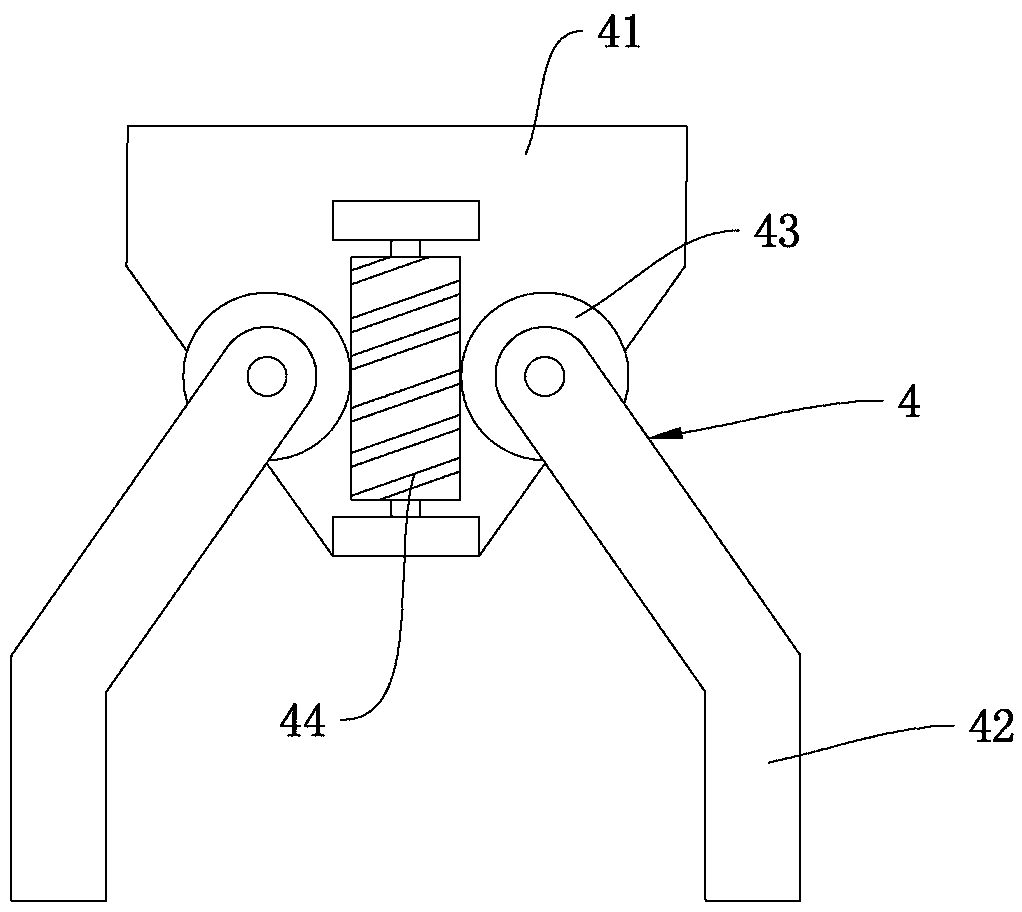

[0018] Example: such as figure 1 and figure 2 As shown, a test tube shaking device includes a supporting base 1, a driving base 2 and a clamping mechanism 4, the driving base 2 is rotatably mounted on the supporting base 1 through a fixed shaft 7, and the clamping mechanism 4 is arranged on the driving base 2 Rotate with driving seat 2 on. The drive base 2 is fixed with a transmission gear 6 , and the drive base 2 and the transmission gear 6 rotate synchronously relative to the fixed shaft 7 and the support base 1 . The supporting base 1 is provided with a driving gear 5 meshing with the transmission gear 6 and a driving mechanism for driving the driving gear 5 forward and reverse. The driving mechanism includes a reduction gear, a motor and a power supply arranged in the support base 1. Several reduction gears are meshed with each other for transmission. At least one reduction gear rotates coaxially with the driving gear 5. The motor adopts a servo motor, and the circuit a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com