Temperature control method and system for rack equipment

A temperature control method and equipment technology, applied in the field of communication, can solve the problems of unbalanced temperature adjustment, speed up fans, increase energy consumption, etc., and achieve the effects of reducing energy consumption, prolonging fan life, and simplifying the analysis and processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

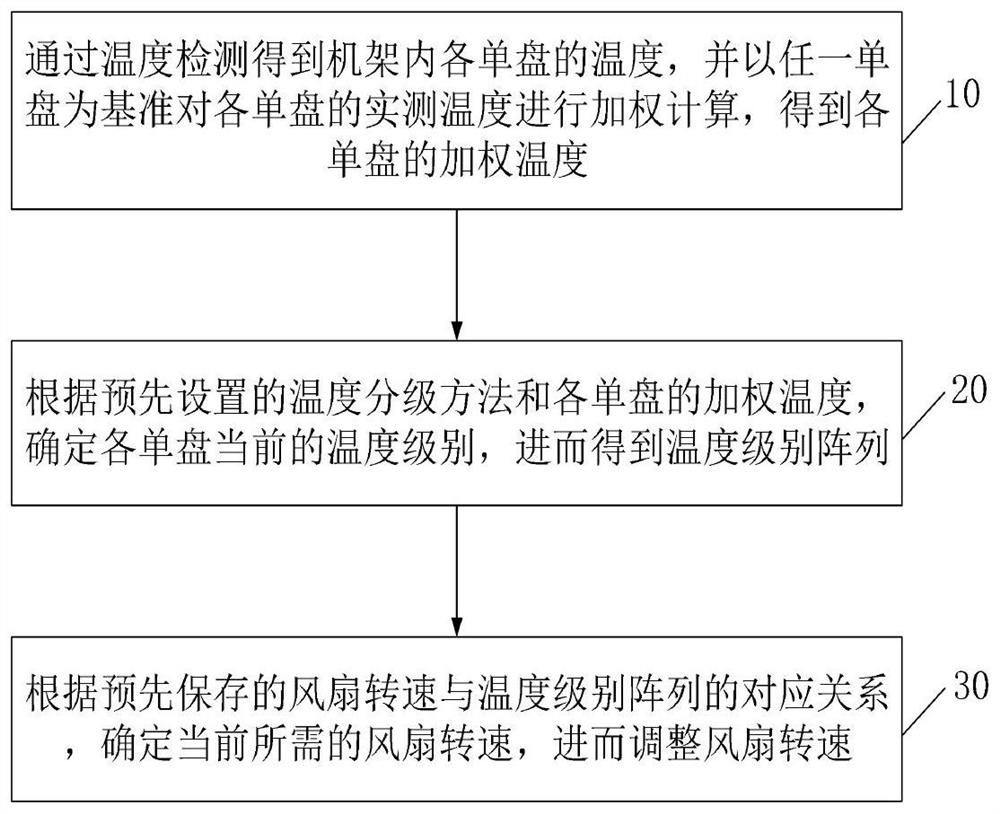

[0040]The embodiment of the present invention provides a temperature control method for rack equipment. There are usually multiple single disks in the rack, including power supply disks, main control disks and service disks, and multiple fan groups. The speed of the fan is adjusted to control the temperature of the single disk, such as figure 1 As shown, the temperature control method provided by the present invention specifically includes the following steps:

[0041] Step 10: Obtain the temperature of each single disk in the rack through temperature detection, and perform weighted calculation on the measured temperature of each single disk based on any single disk to obtain the weighted temperature of each single disk.

[0042] In the rack, each single disk has different requirements for working temperature, but each single disk corresponds to a limit temperature that can keep it working normally, that is, the maximum working temperature. If the temperature exceeds the maxim...

Embodiment 2

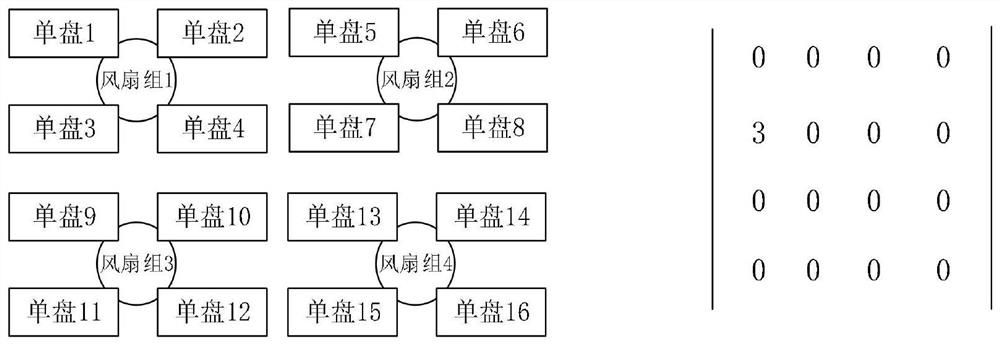

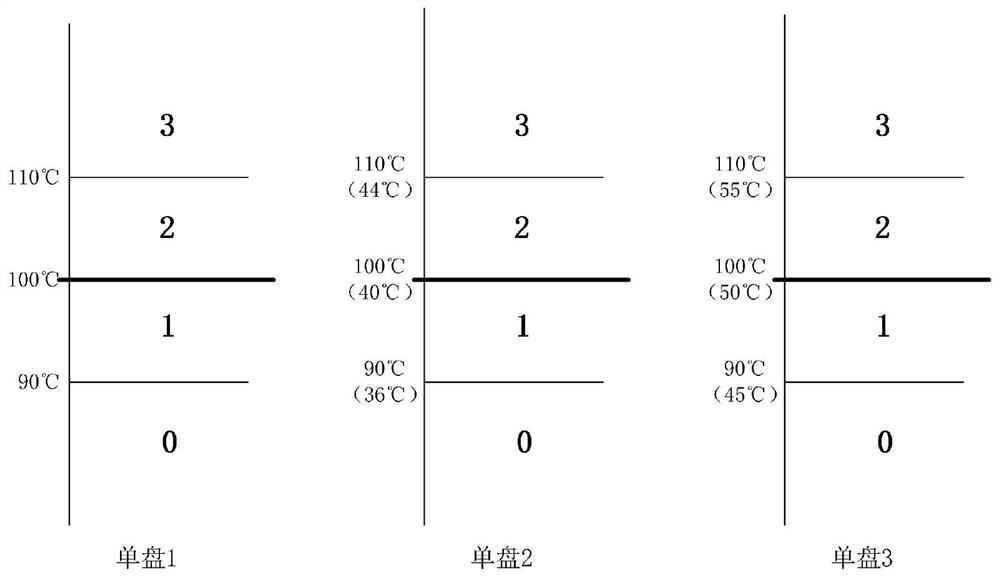

[0053] On the basis of Embodiment 1 above, the present invention also provides a specific embodiment of a temperature control method for rack equipment. In this specific embodiment, it is assumed that there are a total of 16 single disks in the rack, including single disk 1, single disk 2, single disk 3, single disk 4, ..., single disk 15 and single disk 16, and fans Group 1, fan group 2, fan group 3, and fan group 4 have a total of 4 fan groups, and the specific positions of each single disk and each fan group are as follows: figure 2 As shown in the figure on the left, each fan group includes at least one fan. If the maximum working temperature of single disk 1 is T 1max =100℃, the maximum working temperature of single plate 2 is T 2max =40℃, the maximum working temperature of single disc 3 is T 3max =50°C; and taking the maximum operating temperature of single disk 1 as the benchmark, then T max =T 1max = 100°C. Assume that the measured temperatures of single disk 1,...

Embodiment 3

[0059] On the basis of the above-mentioned embodiment 1 and embodiment 2, the embodiment of the present invention further provides a temperature control system for rack equipment, which is used to implement the temperature control method in embodiment 1 and embodiment 2. refer to Figure 5 , the system includes a rack backplane, a plurality of single disks and at least one fan disk, and a single disk can be divided into a power supply disk, a main control disk and a service disk according to functions, and a temperature detection unit and a management unit are arranged in the single disk and a control unit, the fan tray is provided with one or more fan groups, and a drive unit, each fan group includes at least one fan, and the temperature of a single disk is controlled by adjusting the speed of the fans in the fan group.

[0060] continue to refer Figure 5 In the accompanying drawings, there are 1 power supply panel, 1 main control panel, 2 fan panels (respectively denoted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com