Ultrasonic nondestructive detection method of material mico-crack expanded size

A non-destructive testing and micro-crack technology, which is applied in the analysis of materials, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., to achieve high detection accuracy, low detection cost, and fast detection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

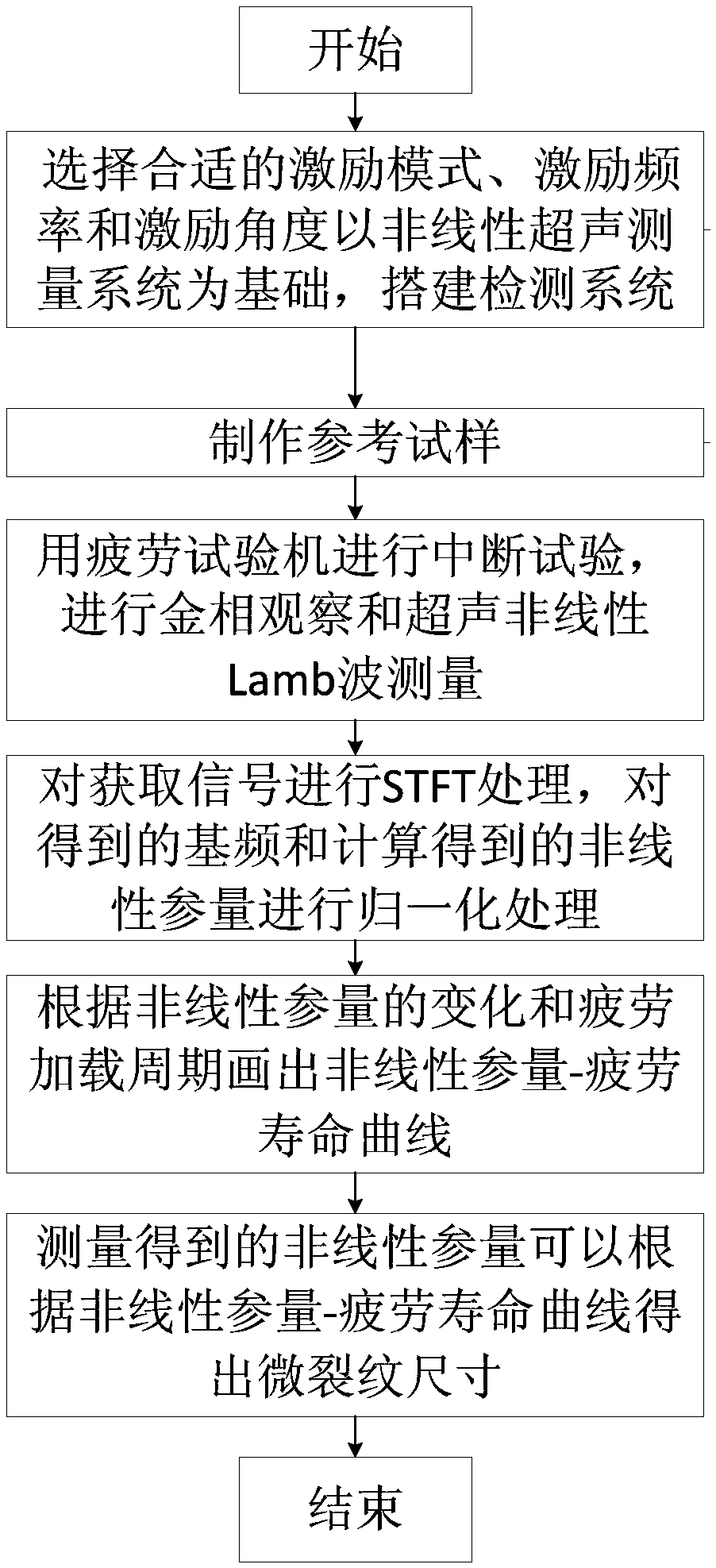

[0025] Such as figure 1As shown, the present invention provides a method for ultrasonic non-destructive testing of material microcrack extension size, the ultrasonic non-destructive testing method adopts such as figure 2 The shown nonlinear ultrasonic Lamb wave measurement system, and the method is used to measure a sample 32 to be tested, specifically comprising the following steps:

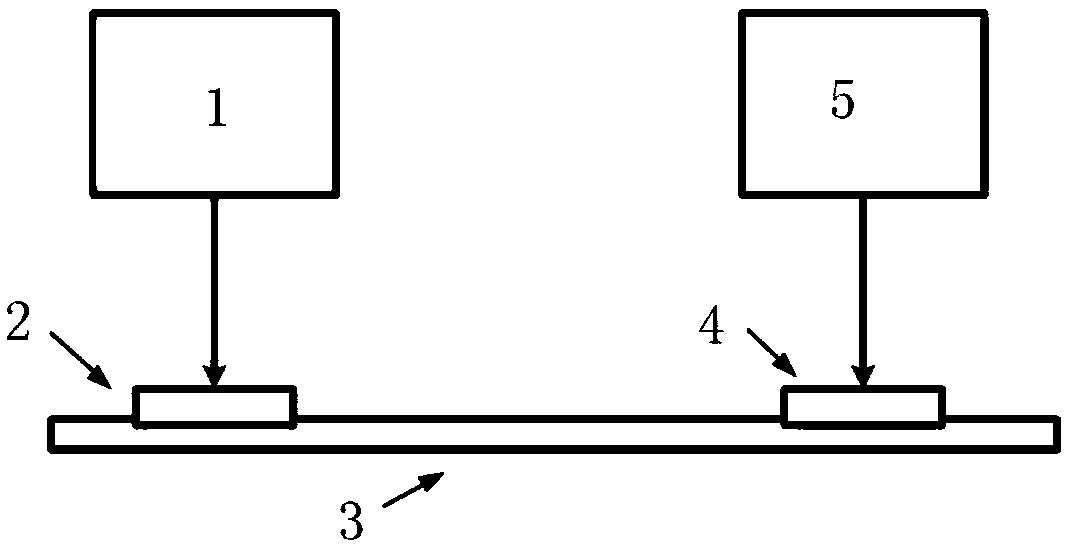

[0026] S1: Build a nonlinear ultrasonic Lamb wave measurement system, the measurement system includes a linear ultrasonic excitation system 1 and an excitation probe 2 electrically connected to each other, and a receiving probe 4 and an oscilloscope 5 electrically connected to each other, the excitation probe 2 and the receiving probe 4 Wedges are provided at the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com