Torsional clamp used on tensile testing machine

A tensile testing machine and fixture technology, applied in the field of torsion fixtures, can solve problems such as coaxial connection of fixtures, no setting, and inability to rotate the machine chuck, so as to achieve the effects of stable experimental process, accurate experimental data, and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

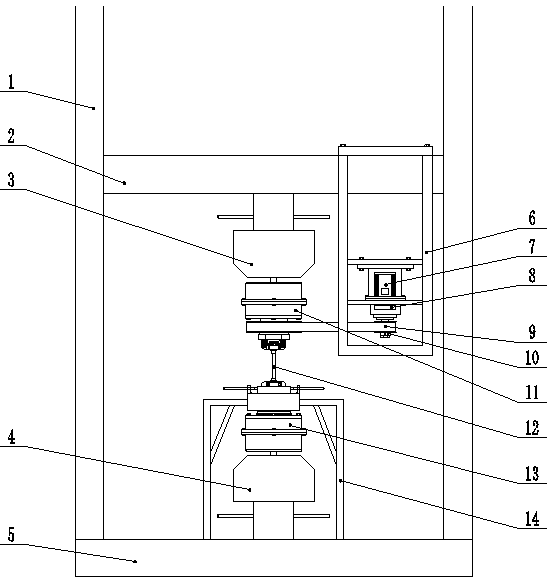

[0036] The present invention provides a torsion fixture used on a tensile testing machine, such as Figure 1 to Figure 12 shown. The torsional fixture used on the tensile testing machine includes a torsional power module, a clamping device module and a hydraulic push structure, and upper and lower coaxial corresponding fixture modules fixed on the machine chuck, defined as the upper fixture module 11 and The lower clamp module 13 ; the corresponding upper clamp 3 clamps the upper clamp module 11 , and the lower clamp 4 clamps the lower clamp module 13 .

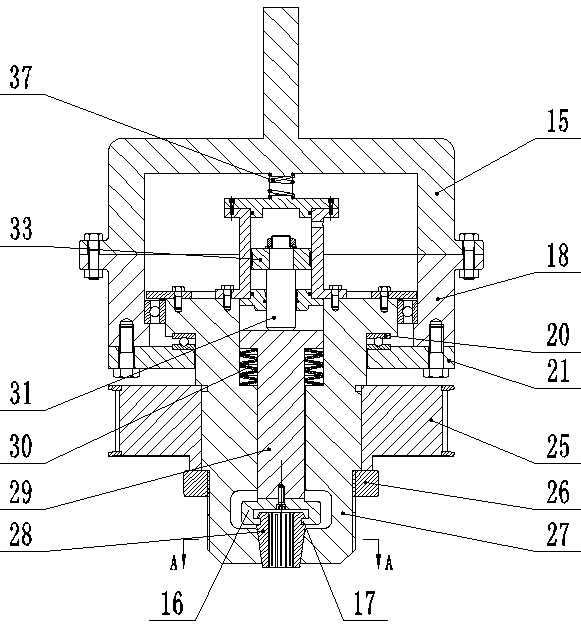

[0037] The clamp module includes a clamp body 27 arranged vertically, a collet push rod 29 arranged inside the clamp body, and a collet 28 for clamping the specim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com