Impact test system based on integral Hopkinson rod PVDF sensor

A Hopkinson rod and impact test technology, which is applied in the direction of instruments, measuring devices, and measuring fluid pressure, etc., can solve the problems of uneven superimposition of pulse signals, short calibration range, etc., and achieve simple calculation, large calibration range, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

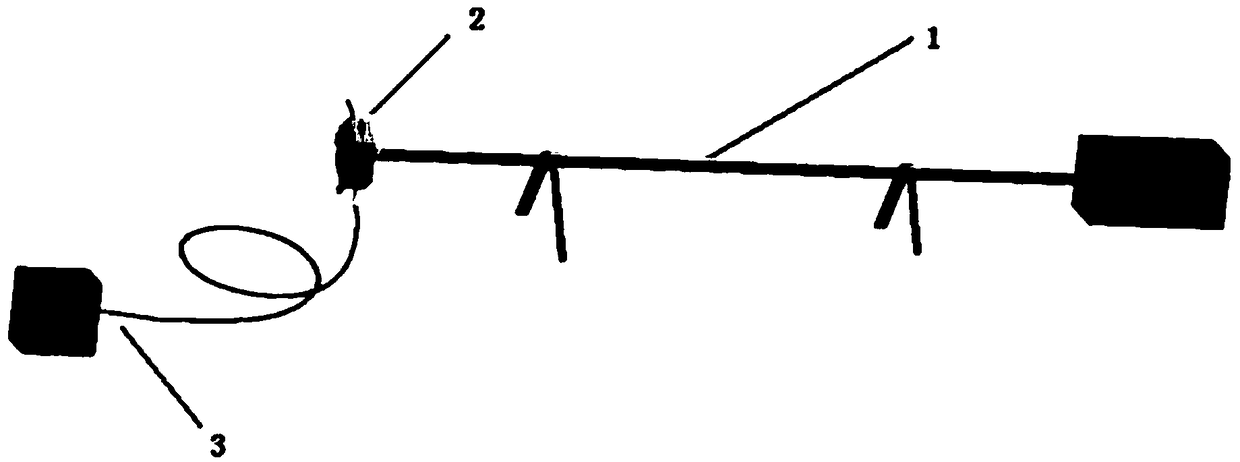

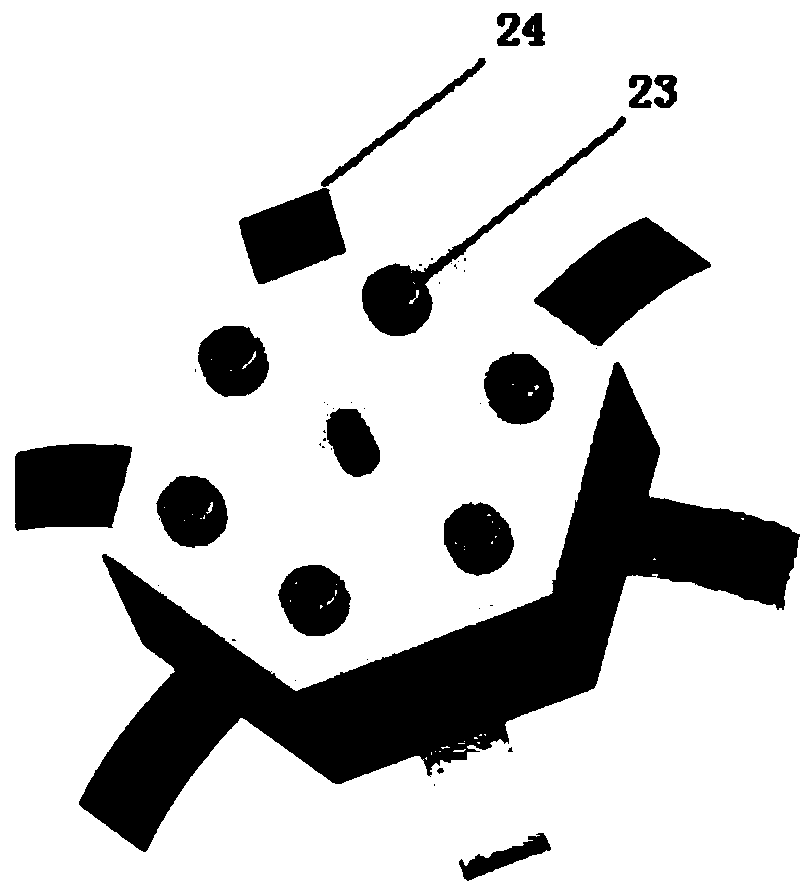

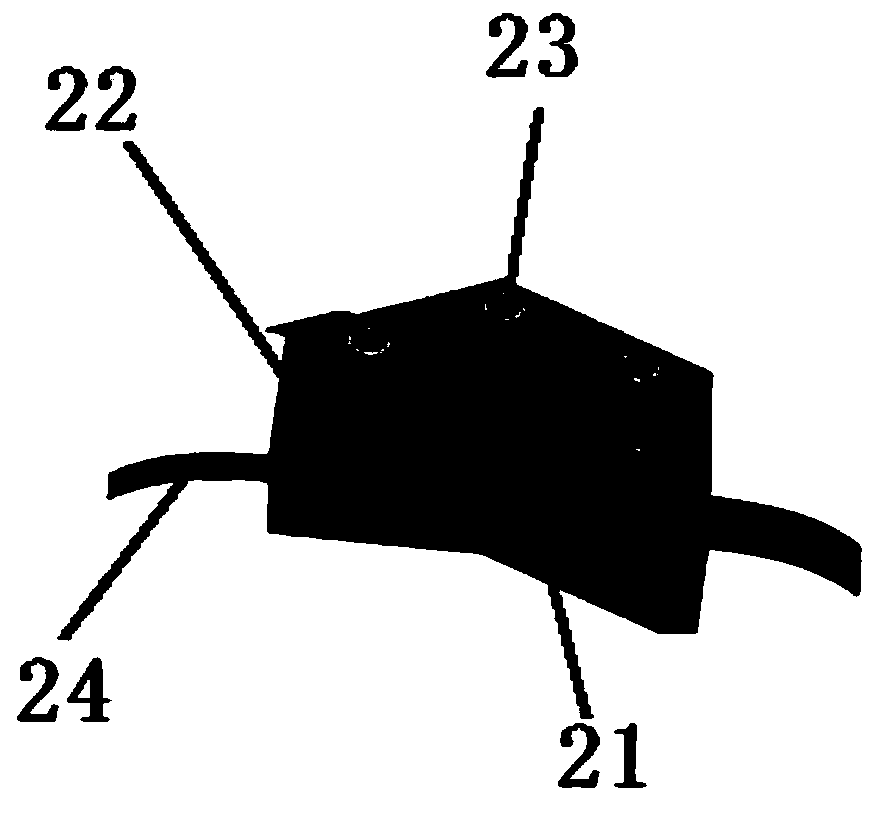

[0013] Specific implementation mode one: combine Figure 1 to Figure 5 Illustrate, a kind of impact test system based on integral type Hopkinson bar PVDF sensor of this embodiment is made up of integral type Hopkinson bar 1, PVDF sensor test assembly 2, signal acquisition system 3; Described integral type Hopkinson bar 1 Integral structure; the PVDF sensor test assembly 2 is fixed on the sample to be tested of the integral Hopkinson bar 1 by threads; It is composed of several PVDF sensors 24, the fixture upper cover 21 and the fixture base 22 are in a concave-convex tight fit and fixed by the fixture fixing screw 23, and the several PVDF sensors 24 are clamped between the fixture upper cover 21 and the fixture base 22 Between; described signal acquisition system 3 is made up of oscilloscope and charge amplifier; Described single PVDF sensor 24 is externally connected with testing wire, and one end of described testing wire is connected on the positive and negative pole of PVDF...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that: the contact surfaces of the PVDF sensor 24 , the fixture upper cover 21 and the fixture base 22 are coated with Vaseline. Others are the same as the first embodiment.

[0020] This embodiment can enhance shock pulse signal transmission.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the standard mechanical value measured by the standard sensor in the integral Hopkinson rod 1 is the acceleration. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com