Draw frame for cotton yarn production and processing

A drawing frame and cotton yarn technology, applied in textiles and papermaking, etc., can solve problems such as inconvenient adjustment, and achieve the effects of reducing the possibility of falling off, convenient adjustment, and convenient folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

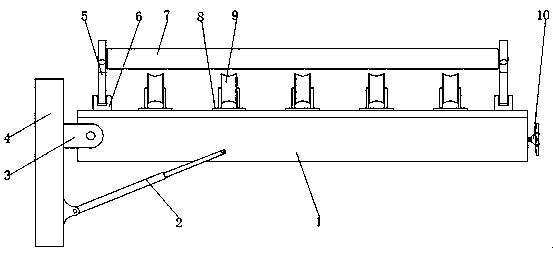

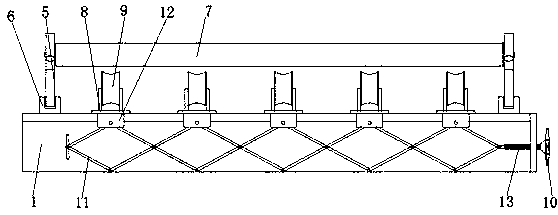

[0018] refer to Figure 1-2 , a drawing frame for cotton yarn production and processing, comprising a support base 4, a hinge block 3 is fixed at the top end of one side of the support base 4 by bolts, and a groove seat 1 is hinged on the side wall of the hinge block 3, and the inner wall of the groove seat 1 is The side thread is connected with a threaded rod 13, and one end of the threaded rod 13 passes through the groove seat 1 and is fixed with a rotating disk 10 by bolts, and one end of the threaded rod 13 is hinged with a universal joint, and the end of the universal joint away from the threaded rod 13 is movably connected with a scissor telescopic Frame 11, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com