A kind of marine silt composite curing agent

A composite curing agent and silt technology, applied in the engineering field, can solve the problems of high energy consumption and large cement consumption, and achieve the effects of reducing water content, good water absorption, and solving large cement consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

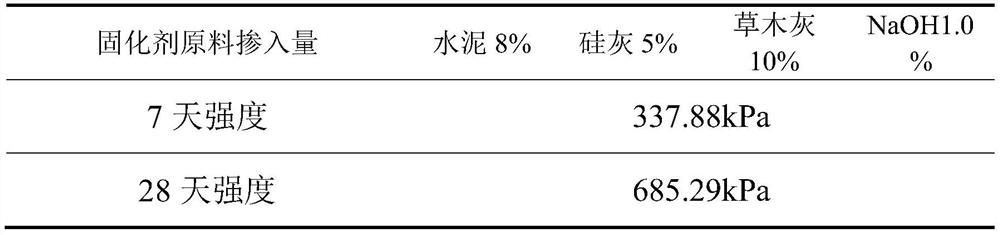

Embodiment 1

[0021] A marine silt solidifying agent, its raw materials include: 8% cement, 5% silica fume, 10% plant ash, and 1.0% NaOH in terms of mass fraction. Mix the weighed cement, silica fume, plant ash and dry soil evenly, then pour the weighed NaOH into the pre-weighed water and stir until it does not generate heat, then fully mix the solution with the previous dry soil mixture, Make 3 parallel samples and put them into a mold with a diameter of 3.91cm and a height of 8cm, and place them in a curing room with a temperature of (20±2)°C and a humidity greater than 90% for standard curing for 24 hours, then demould. Continue curing until 7 days and 28 days to measure its unconfined compressive strength. The measured intensities are shown in Table 1.

[0022] Table 17-day and 28-day strength tables

[0023]

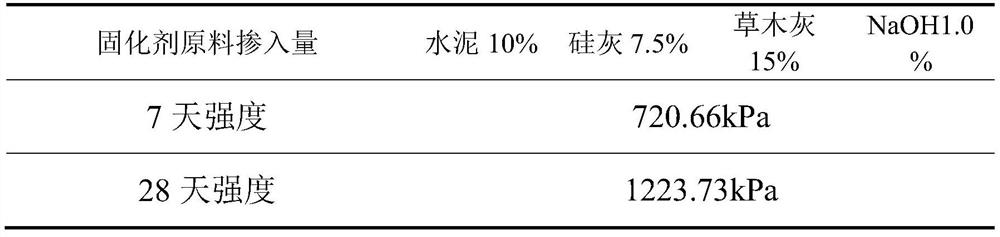

Embodiment 2

[0025] A marine silt solidifying agent, its raw materials include: 10% cement, 7.5% silica fume, 15% plant ash, and 1.0% NaOH in terms of mass fraction. Mix the weighed cement, silica fume, plant ash and dry soil evenly, then pour the weighed NaOH into the pre-weighed water and stir until it does not generate heat, then fully mix the solution with the previous dry soil mixture, Make 3 parallel samples and put them into a mold with a diameter of 3.91cm and a height of 8cm, and place them in a curing room with a temperature of (20±2)°C and a humidity greater than 90% for standard curing for 24 hours, then demould. Continue curing until 7 days and 28 days to measure its unconfined compressive strength. The measured intensities are shown in Table 2.

[0026] Table 27-day and 28-day strength tables

[0027]

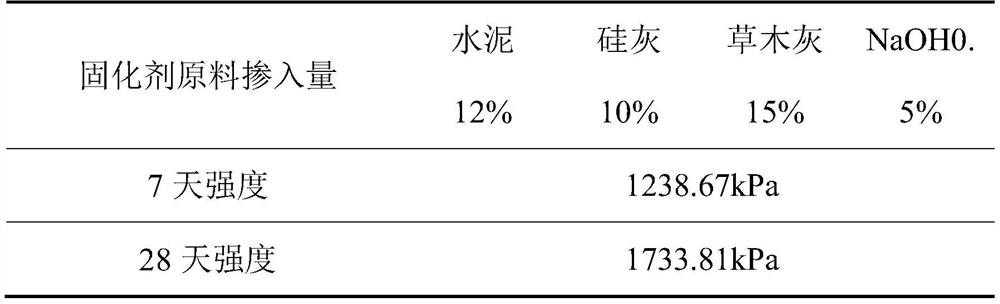

Embodiment 3

[0029] A marine sludge solidifying agent, its raw materials include: 12% cement, 10% silica fume, 15% plant ash, and NaOH: 0.5%. Mix the weighed cement, silica fume, plant ash and dry soil evenly, then pour the weighed NaOH into the pre-weighed water and stir until it does not generate heat, then fully mix the solution with the previous dry soil mixture, Make 3 parallel samples and put them into a mold with a diameter of 3.91cm and a height of 8cm, and place them in a curing room with a temperature of (20±2)°C and a humidity greater than 90% for standard curing for 24 hours, then demould. Continue curing until 7 days and 28 days to measure its unconfined compressive strength. The measured intensities are shown in Table 3.

[0030] Table 37-day and 28-day strength tables

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com