Detection method and system for on-board equipment of locomotive

A vehicle-mounted equipment and detection method technology, applied in the direction of railway auxiliary equipment, railway signals and safety, etc., can solve the problems of low efficiency of production and operation of locomotive on-board equipment, low efficiency of detection operation, failure to discover and deal with equipment failures and hidden dangers, etc. To achieve the effect of improving the efficiency of production operations, reducing the workload of operations, and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

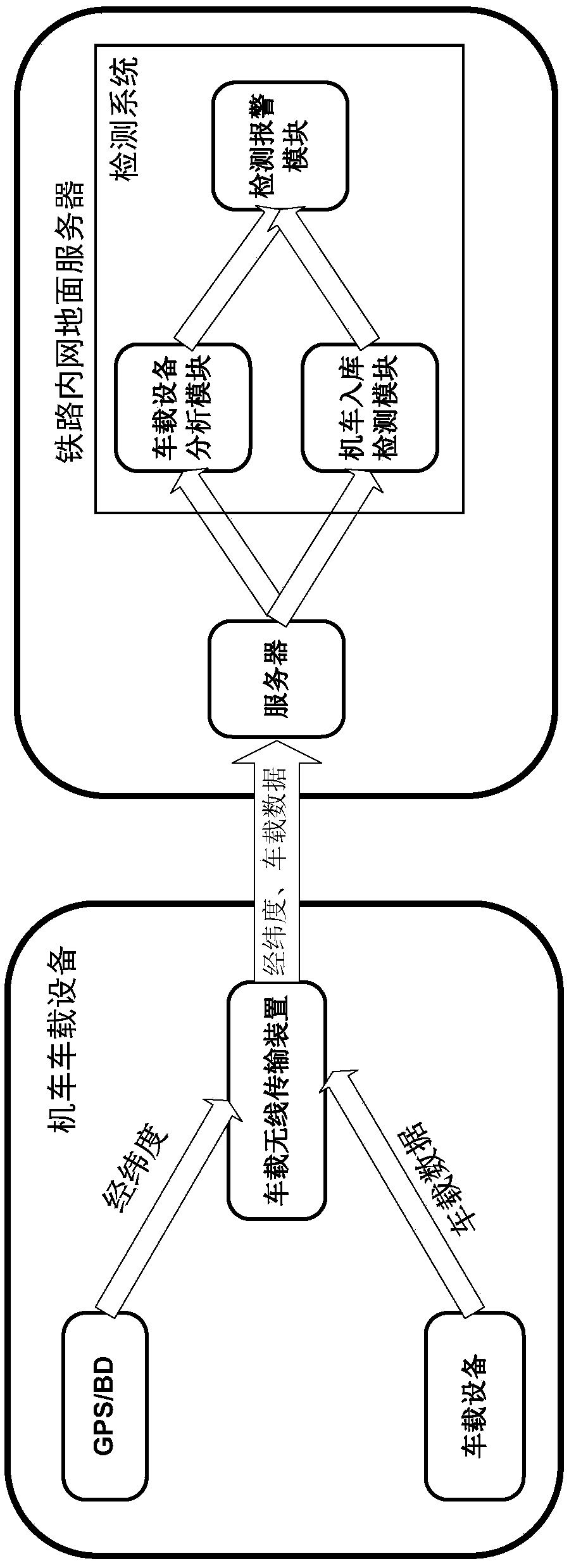

[0046] figure 1The structure of an embodiment of the detection system of the locomotive on-board equipment of the present invention is shown. In this embodiment, the detection system is deployed on the ground server of the railway intranet to receive data from the on-board equipment of the locomotive. In the locomotive on-board equipment, the GPS / BD module provides the geographic location information of the locomotive (such as latitude and longitude data), and the on-board equipment module provides on-board data. The on-board data and latitude and longitude data are transmitted to the ground of the railway intranet through the on-board wirele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com