Power system of hybrid vehicle

A power system and hybrid vehicle technology, applied in hybrid vehicles, motor vehicles, power plants, etc., can solve problems affecting vehicle endurance performance, increase transmission size, complex clutch structure, etc., to improve performance and endurance, reduce The effect of overall quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

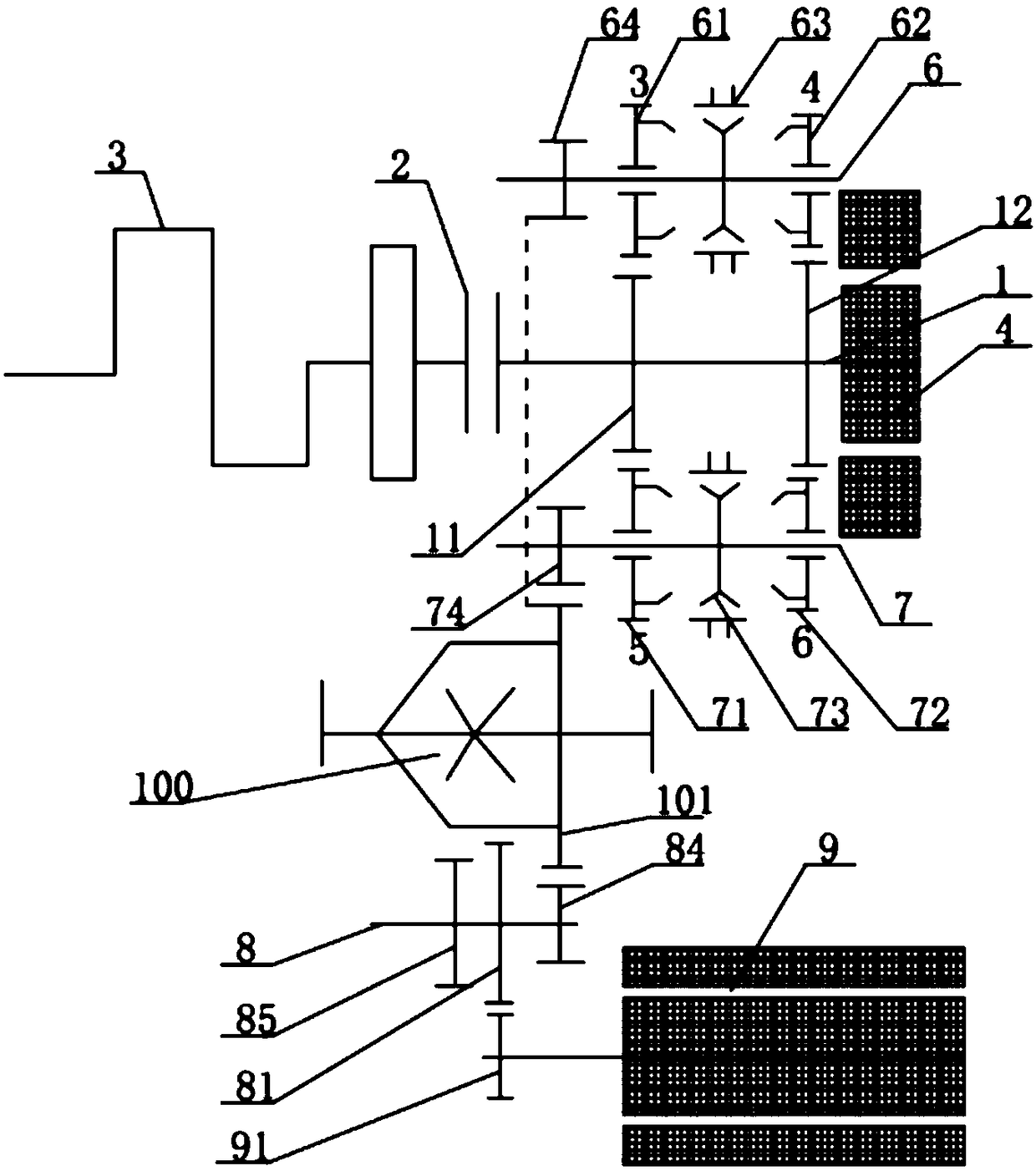

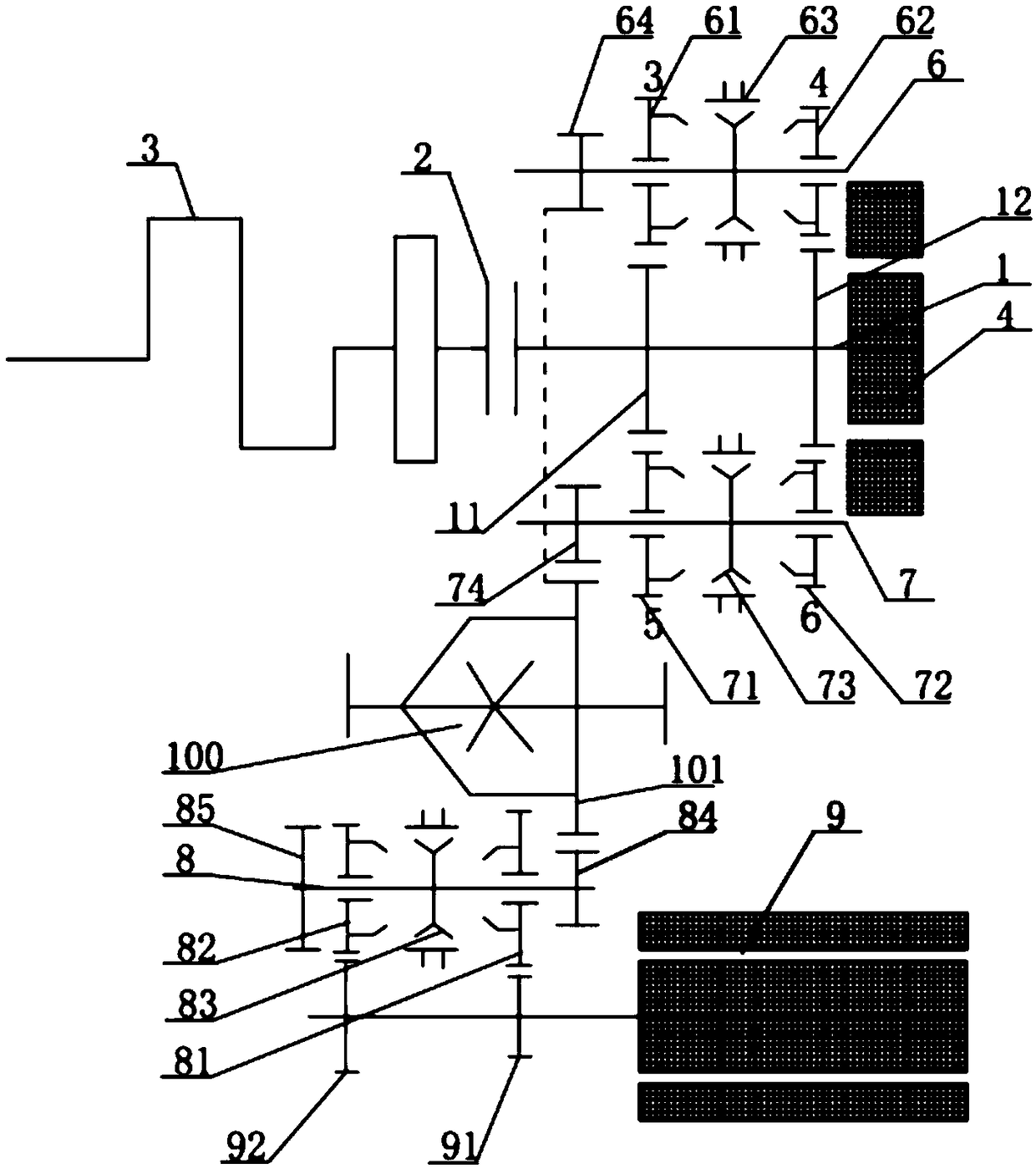

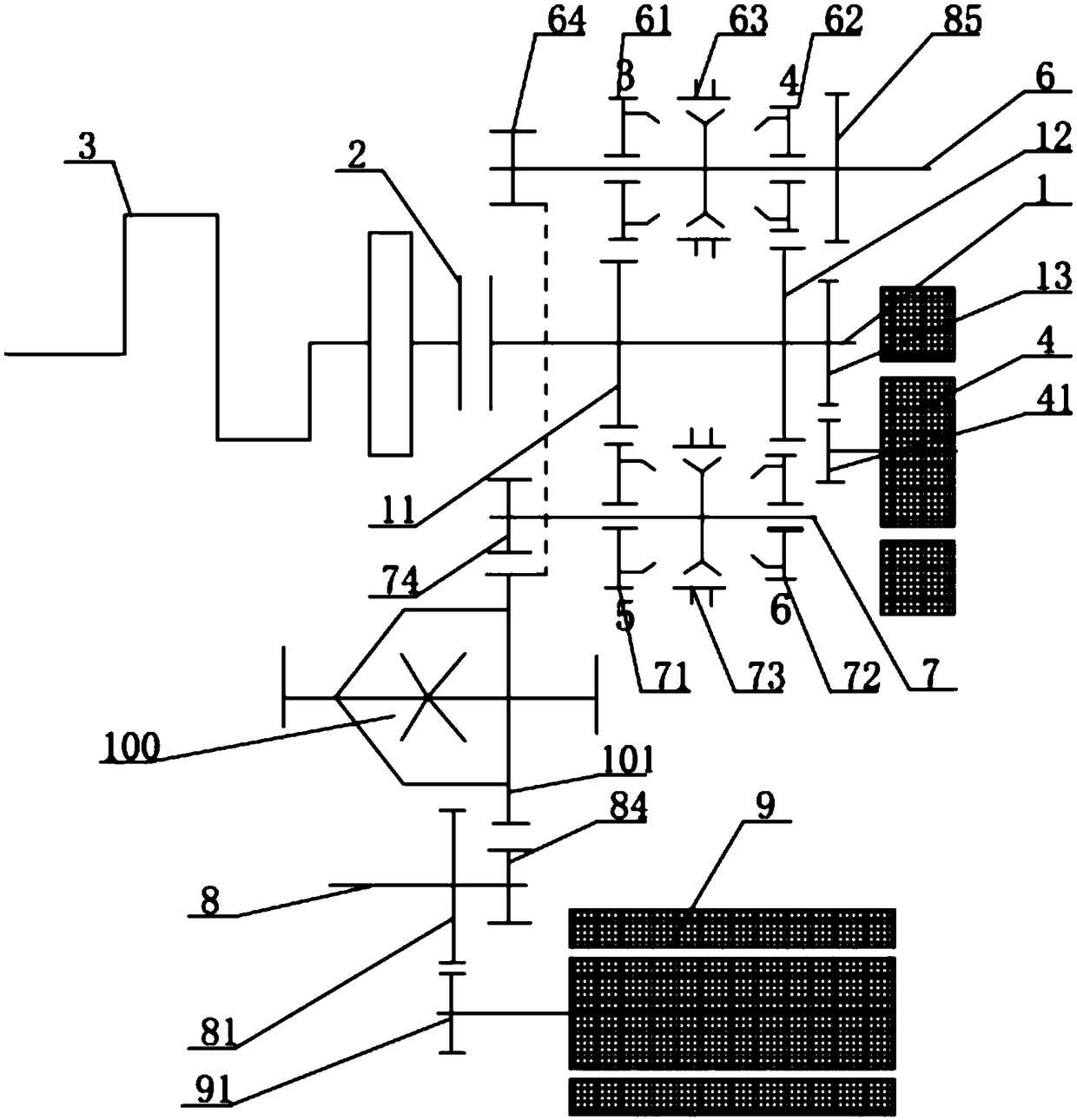

[0037] like figure 1As shown, the first embodiment of the present invention discloses a hybrid vehicle power system, including an input shaft 1 arranged in a gearbox housing, and one end of the input shaft 1 is fixedly connected to an engine 3 through a clutch 2 and a dual-mass flywheel , the dual mass flywheel can provide inertia and stable output for the engine. The other end of the input shaft 1 is connected to the auxiliary motor 4 that can control its rotation. Specifically, the rotor of the auxiliary motor 4 is fixed on the input shaft 1. At this time, the central axis of the auxiliary mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com