Light weight and high strength balance bridge

A high-strength, lightweight technology, applied in the field of auto parts, can solve the problems of inconvenient maintenance and replacement, and achieve the effects of convenient disassembly, overall weight reduction, and convenient use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

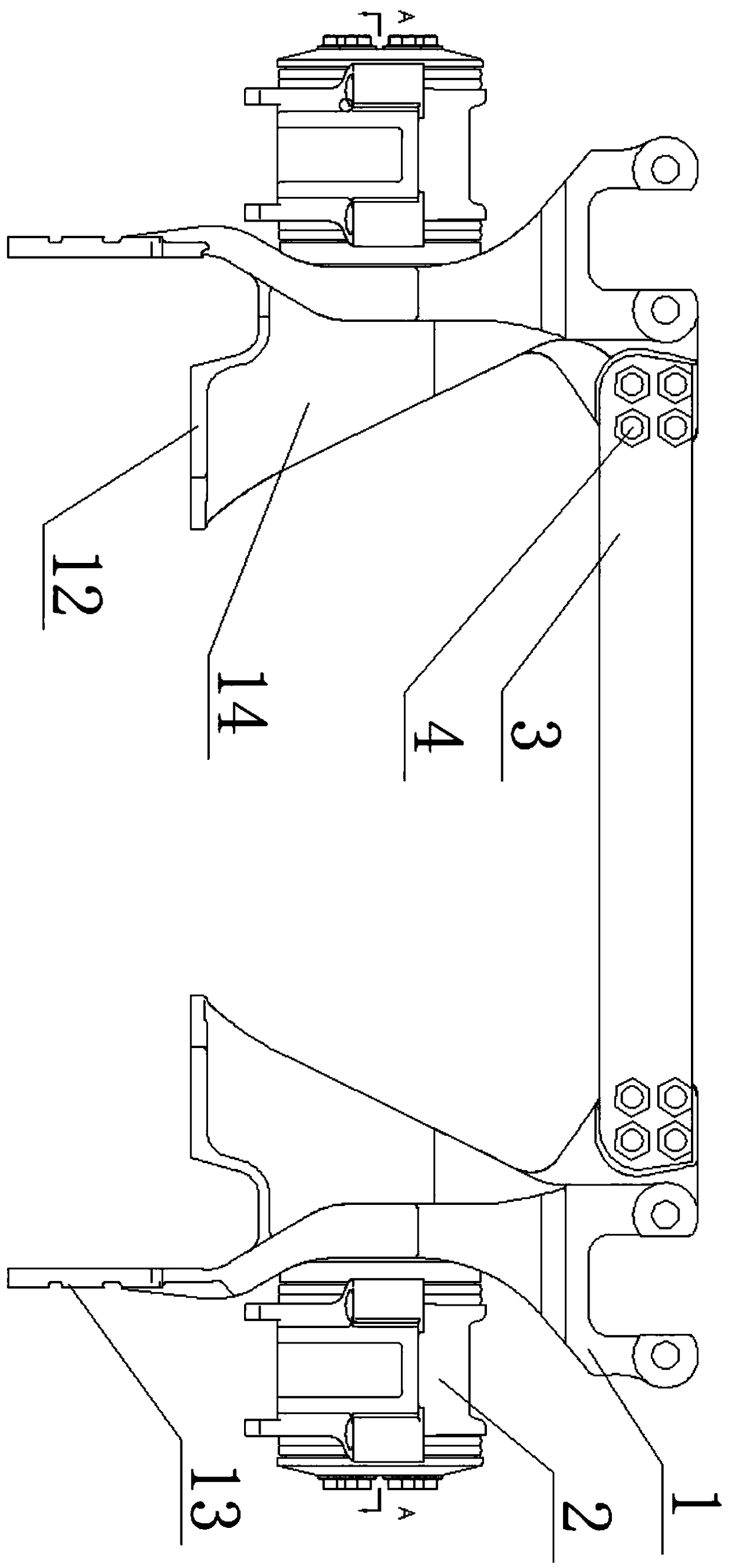

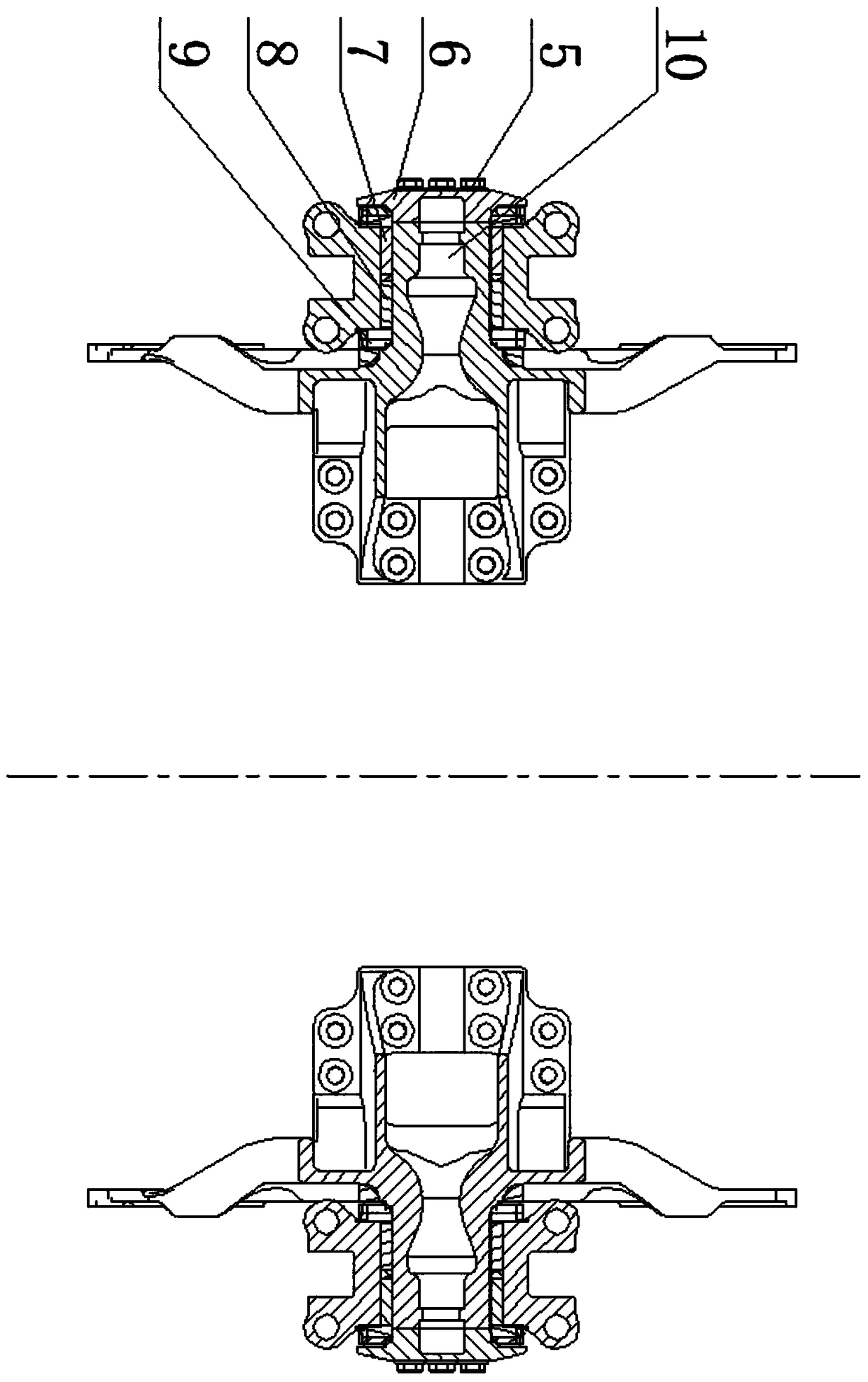

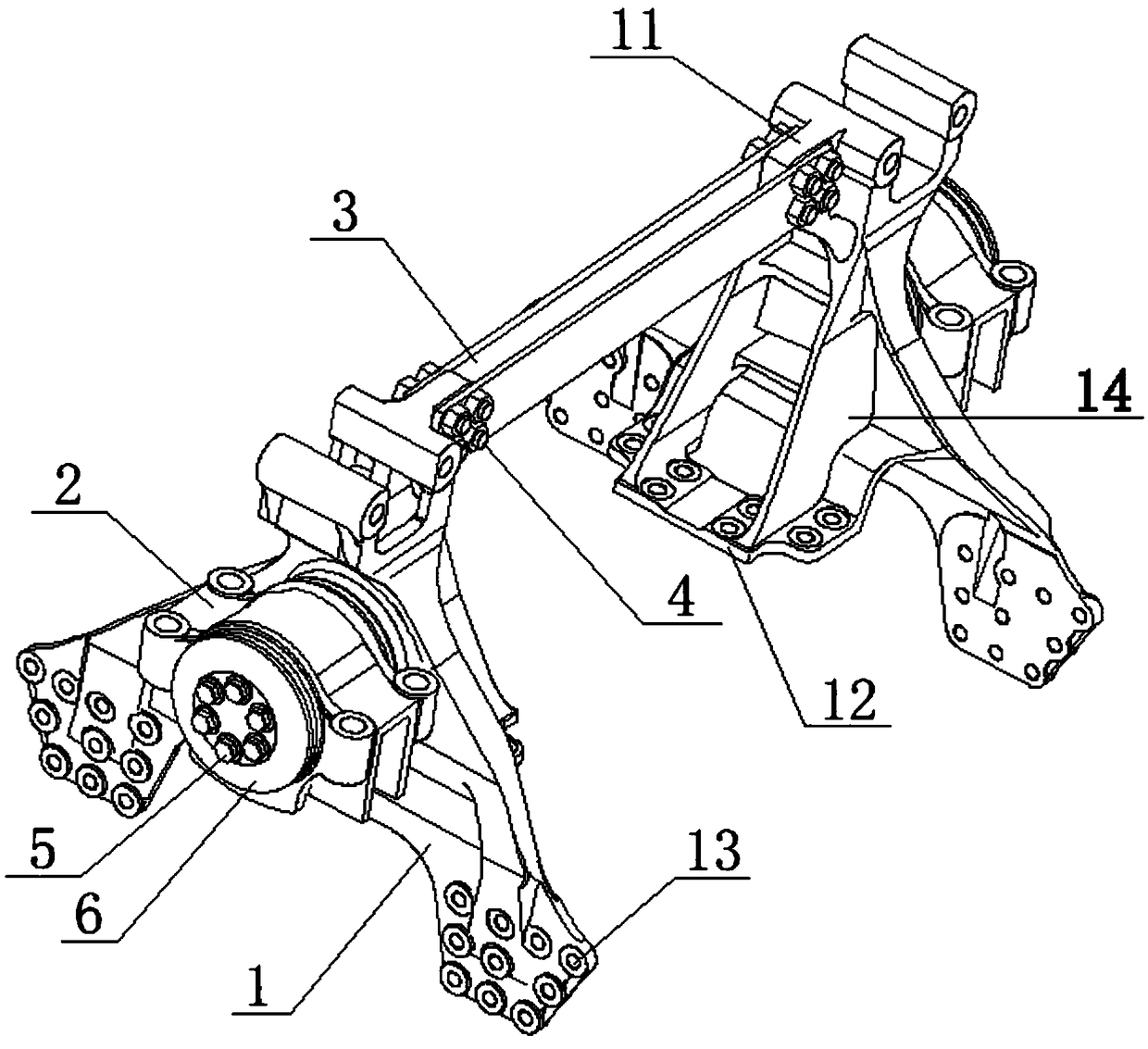

[0030] Such as Figure 1 to Figure 3 A light-weight and high-strength balance bridge is shown, including two connecting brackets 1, a balance shaft 10 that fits loosely with the connecting bracket 1, and an integral leaf spring seat 2 installed on the balancing shaft 10. The connecting bracket 1 is made of high-strength Made of castings, the integral leaf spring seat 2 is connected to the leaf spring through U-shaped bolts; the upper part of the connecting bracket 1 is connected to the thrust rod, and the upper ends of the two connecting brackets 1 are fixedly connected to the relative position of the bolt mounting plate 11, and the bolt mounting plate 11 A plurality of bolt holes are provided on the surface of the bolt mounting plate 11, and connecting bolts 4 are penetrated in the bolt holes of the bolt mounting plate 11, and the two ends of the connecting bolts 4 extend to the outer surfaces of the two connecting plates 3 and are screwed with nuts, and the connecting bolts 4...

Embodiment 2

[0034] Such as Figure 4 A lightweight high-strength balance bridge shown, the rest is the same as in Embodiment 1, the difference is that: the middle parts of the two connecting plates 3 are provided with protrusions, and both ends of the protrusions are excessively connected to the slope of the connecting plates Connection, which can increase the bending strength of the connecting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com