Sport ball and sport ball making method

A production method and technology of sports balls, which are applied to sports accessories, balls, inflatable hollow balls, etc., can solve the problems of weak interconnection, complicated manufacturing process, easy cracking and damage, etc., and achieve good economic value and suture The effect of precise connection and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings. In this embodiment, football is taken as an example to illustrate the technical solution of the present invention.

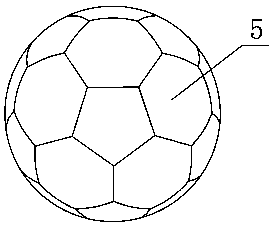

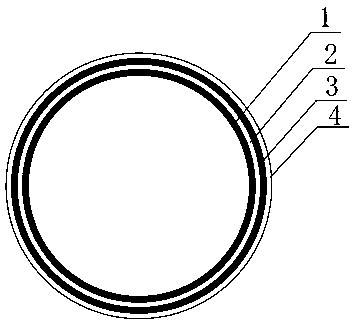

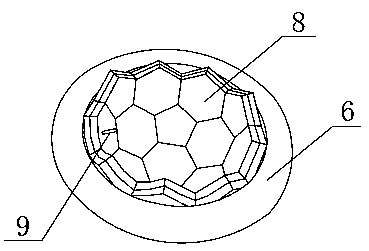

[0033] Such as figure 1 and figure 2 As shown, the sports ball of the present invention includes four layers of rubber inner container 1, yarn wrapping layer 2, glued layer 3 and leather layer 4. The rubber liner 1 is spherical and has a normally closed air vent. The yarn-wrapped layer 2 is distributed on the surface of the rubber liner 1, and the glued layer 3 is wrapped on the outside of the yarn-wound layer 2, and the glued layer 3 is vulcanized and glued to the outer leather layer 4. , leather layer 4 is made up of several skin sheets 5 that constitute football surface. The rubber liner 1 is the innermost structure of the sphere, which is made of natural rubber through vulcanization of the mould, and is used to store g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com