A structure and design method of a double three-hole vertical Hall device

A vertical Hall and device structure technology, applied in the direction of Hall effect devices, electric solid state devices, semiconductor devices, etc., can solve the problems of large initial imbalance, asymmetric current flow path, and difficulty in quantifying and determining the overall influence of the device, achieving Effects of reducing initial offset, avoiding short-circuit effects, and optimizing distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

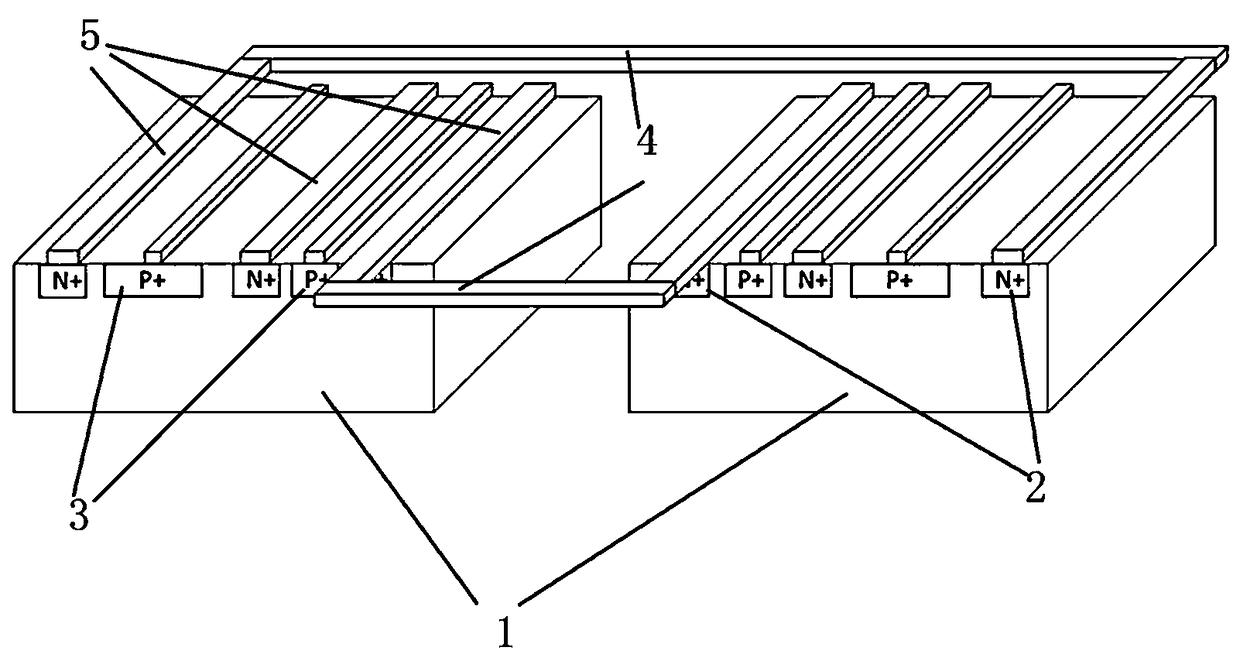

[0039] Such as Figure 1-5As shown, a double-three-hole vertical Hall device structure, the Hall device structure forms an axisymmetric structure with two identical three-hole vertical Hall devices 1 arranged side by side; There is an isolation structure between them; the N wells of the two three-hole vertical Hall devices are independent of each other and are located on the same level; the N wells are provided with three N+ regions 2 arranged in parallel in order to form a three-hole structure, and the three N+ regions Both are connected with contact electrodes 5; two three-hole vertical Hall devices are connected with contact electrodes at their edges via wires 4 to form an assembly.

[0040] The N+ is in the shape of a rectangular strip; on the N well of each three-hole vertical Hall device, the widths of the separation regions used to separate adjacent N+ regions are not equal.

[0041] A P+ region 3 is provided at each separation region; the P+ region is used to neutrali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com