A Fault Degradation State Prediction Method for Closed-loop Control System of Steam Turbine Bearings in Smart Power Plant

A closed-loop control, intelligent power plant technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve problems such as indistinguishability, and achieve the effect of timely adjustment and avoiding malignant failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

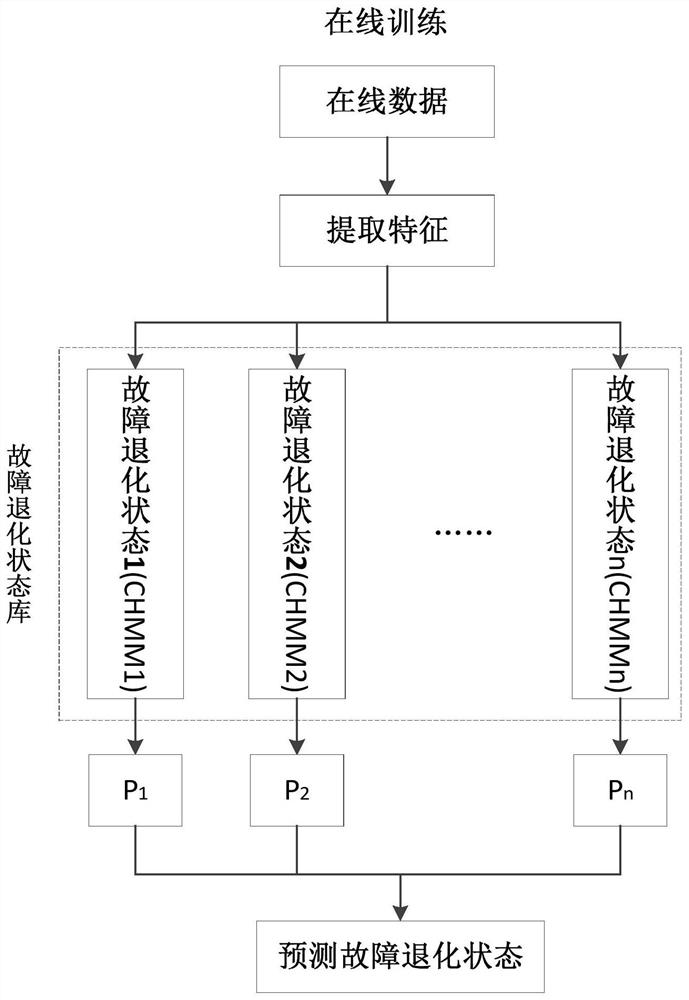

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

[0048] As one of the most important basic industries in the national economy, thermal power generation is an important indicator to measure a country's economic level and comprehensive national strength. There are a large number of closed-loop control systems in large-scale thermal power generating units, among which the closed-loop control system of steam turbine bearings plays a vital role in the healthy operation of large-scale thermal power generating units. Therefore, in the process of promoting the development of smart power plants, it is of great significance to study the prediction method of the fault degradation state of the closed-loop control system of the steam turbine bearing. The present invention takes No. 5 unit of Jiahua Thermal Power Plant as an example, and the power of this unit is 10000MW. The closed-loop control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com